The wind power and construction machinery industries demand exceptional precision, durability, and reliability in the machining of large-scale, high-strength components. These sectors require cutting tools that can handle complex structures, hardened materials, and high-volume production. Halnn, as a leading manufacturer of superhard cutting tools, offers comprehensive and customized machining solutions for key parts such as gears, bearings, shafts, planetary carriers, hydraulic valves, hubs, and blades. We help manufacturers achieve higher efficiency, longer tool life, and reduced production costs.

Bearings | Gears | Drive Shafts | Main Shafts |

|  |  |  |

Hubs | Planetary Carriers | Blades | Hydraulic Valves |

|  |  |  |

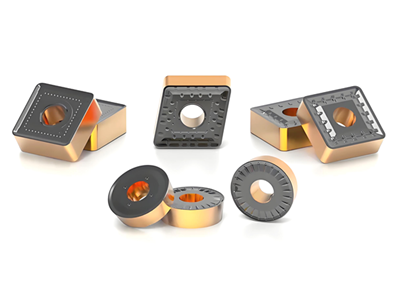

Pre-Heat Turning |  | Carbide inserts are used for rough machining of gear end faces, bearing inner/outer diameters, and shafts, supporting deep cuts and high productivity. |

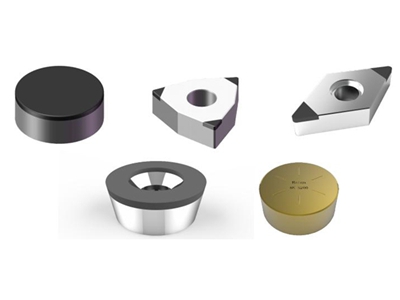

Post-Heat Hard Turning |  | CBN inserts are ideal for hardened components (HRC60+), offering outstanding wear resistance, dimensional stability, and surface quality. |

Gear Profile Milling |  | Rough and pre-grind milling cutters for high-accuracy gear profiles. Long tool life and consistent performance. |

High-Speed Gear Hobbing |  | Suitable for modules M5–M38 with optimized tooth arrangements for rough and semi-finishing of external teeth. |

Gear Shaper Cutters |  | Designed for small-module (M3.5–M10) and internal gears. Indexable design, no regrinding required. |

Planet Carrier Milling |  | Anti-vibration three-edge cutters engineered for large overhangs and deep cuts, reducing chatter and improving efficiency. |

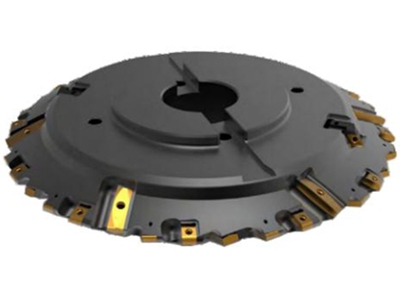

Hub Milling |  | Multi-edged double-sided inserts with extremely high material removal rates. |

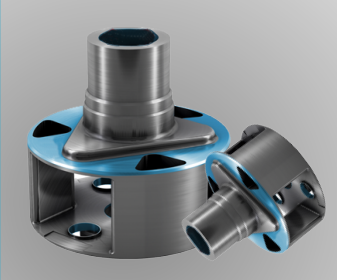

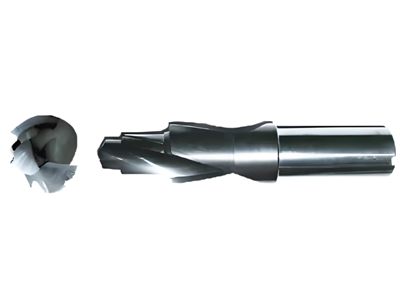

Crown Drill |  | Quick-change design, internal cooling, and excellent chip evacuation for complex deep-hole drilling in hubs and bearings. |

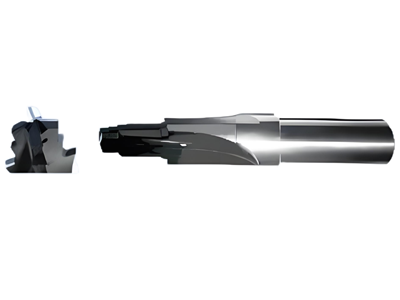

Gun Drills |  | Available in brazed, solid carbide, and indexable designs, suitable for Ra <2 finish. Custom depths supported. |

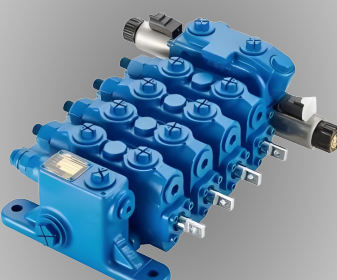

Hydraulic Valve Drilling |  | Composite drills, reamers, and T-slot cutters ensure Ra0.4–Ra0.8 surface finish and high alignment precision. |

Blade Machining |  | PCD inserts minimize burrs and delamination when drilling composite materials. |

Staggered Tooth Thread Mills |  | For large-diameter internal threads (M30–M64), high-speed cutting with internal cooling and lower tooling cost. |

Thread Taps |  | TIN-coated HSS taps for high-hardness materials (HB280–330), offering excellent chip control and guidance. |

Damping Boring Tools |  | Designed for large overhangs with low-vibration performance to ensure excellent surface finishes. |

CMR / CMB Rough and Finish Boring Tools |  | Standard and non-standard solutions for high-precision hole machining in hubs and planetary carriers. |

Composite Forming Reamers |  | Used in hydraulic valve machining, achieving Ra0.4 surface roughness for sealing and assembly accuracy. |

Comprehensive Tool Range: CBN, PCD, carbide, and composite tools available

High Performance: Long tool life, stable machining, and high cutting speeds

Custom Solutions: Tailored non-standard tools to match customer requirements

Technical Expertise: Support for process optimization and tool application

Industry Experience: Proven success across wind energy, construction, and heavy industries

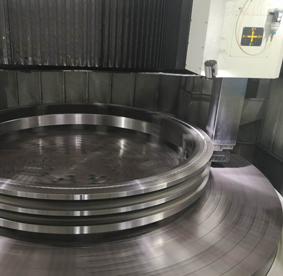

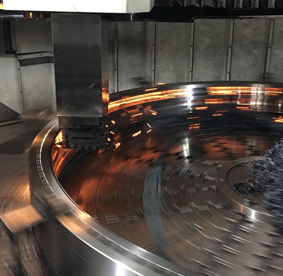

Processing part: Wind power bearing, Inner Ring Rib |  |

Processing size: 2750mm | |

Material: 42CrMo4 | |

Hardness of Bearing: 58-63 HRC | |

Surface Roughing: Ra 0.4 | |

Inserts Type:BN-H200 RNGN090300 | |

Machining way:Roughing | |

Machining parameter:Vc=190m/min Fr=0.32mm/r, Ap=0.6-0.7mm | |

Machining way: Finishing | |

Machining parameter:Vc=215m/min,Fr=0.2mm/r,ap=0.2mm |

| Processing part: Wind power bearing, Outer Ring Raceway |

Processing size: 2750mm | |

Material: 42CrMo4 | |

Hardness of Bearing: 58-63 HRC | |

Inserts Type:BN-H200 RNGN090300 | |

Machining way:Roughing | |

Machining parameter:Vc=190m/min, Fr=0.43mm/r, Ap=1mm | |

Machining way: Finishing | |

Machining parameter:Vc=260m/min,Fr=0.2mm/r,ap=0.1mm |

Part: Reducer gear Processing site:Inner tooth apex Size:φ1300 Other solid CBN: RNMN090400 Machining parameter:Vc=80m/min Fr=0.3 Ap=0.3 Difficulties:One insert cannot complete processing and breakdown Halnn PCBN BN-H200: RNMN090300 Machining parameter: Vc=100m/min Fr=0.3 Ap=0.3 Tool life: Machining 2 PCS with one cutting edge |

|

Part: Gear for Wind Power Reducer Rough turning end face and inner hole Original CBN insert, CNGA120412 Original parameters: VC=120m/min, f=0.2, ap=0.7, diameter D=509 Lifespan: 2 products for a single cutting edge Improved CBN insert, Halnn RNGN060300 Processing parameters: VC=119m/min, f=0.3, ap=0.7, diameter D=509 Lifespan: 2 products for a single cutting edge With the same parameters, under the hard conditions of ensuring a minimum lifespan of 2 PCS, circular blades exhibit more stable performance in complex working conditions. |

|

Part: Gear for Wind Power Reducer Fine turning end face and inner hole Original CBN insert, DNGA150412 Original parameters: VC=130m/min, f=0.1, ap=0.2, diameter D=509 Lifespan: 1 product for a single cutting edge Improved CBN insert, Halnn WNGA080408-WH with wiper Processing parameters: VC=150m/min, f=0.3, ap=0.2, diameter D=509 Lifespan: 1 product for a single cutting edge For the inner hole of the large diameter gear ring, the roughness of the workpiece can still be controlled within 0.6 after the deep inner hole machining of the Halnn BN-H200. The processing time of a single piece has been reduced from 24 minutes to 8 minutes, and the processing efficiency has been increased by three times. |

|

Heat-treated bearings, such as wind turbine bearings, metallurgical bearings, and wheel hub bearing units, generally have a hardness above HRC50, which puts high demands on the wear resistance and life of the tool.

Large-scale bearings, such as wind turbine bearings, have large diameters. After heat treatment, the machining allowance is 2-6mm, and the machining allowance is uneven. Moreover, there are oil holes in the lunar groove of the outer ring raceway of the machining part. The tool needs good impact resistance and toughness. It will break easily. At the same time, bearings have higher requirements for accuracy and surface roughness. For example, the accuracy tolerance of the raceway radian of the wind turbine bearing is 0.08, and the surface roughness of the raceway is Ra0.4.

With the continuous development of the modern tool industry, the cubic boron nitride (CBN) tool BN-H200 material developed by the superhard material industry effectively solves the problem of difficult bearing machining and can meet the requirements of high quality, high efficiency and low cost at the same time.

Get in Touch for Tailored Machining Solutions

Asia: asia@halnn-group.com

Europe: europe@halnn-group.com

Americas: americas@halnn-group.com

At Halnn, we are committed to delivering efficient, stable, and customized cutting tool solutions for the wind power and construction machinery industries.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone