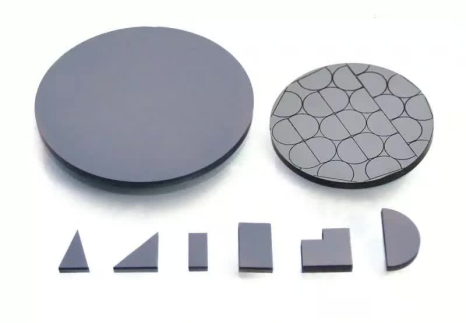

Full Name: PCBN blanks, Polycrystalline Cubic Boron Nitride blanks, PCBN Cutting Tool Blanks, CBN Blank, Round CBN blanks

Application field: Turning tools, milling tools, hard turning tools

Machining Materials: Hardened steel and cast iron etc. high hardness and hard processed ferrous materials (HRC45-65).

Machining workpiece: Brake discs, engine blocks, engine cylinder liners, brake drums, flywheels, valve seats and guides, gears, mold and die parts, etc.

Hardness is generally HV3000 ~ 5000;

Heat resistance is up to 1400 ~ 1500 °C;

And it has good red hardness and high oxidation resistance, so that no oxidation occurs at 1000°C; and no chemical reaction occurs at 1200 to 1300°C with iron-based materials;

High cost-effective, Easy Processing, Excellent performance, High wear resistance, strong stability;

The thermal conductivity of PCBN cutting tool is lower than that of diamond but much higher than that of cemented carbide, which is conducive to the improvement of workpiece processing precision and surface finish. The friction coefficient of PCBN tool processing of different materials is between 0.1 and 0.3, which is much lower than that of cemented carbide. The coefficient (0.4 ~ 0.6) makes it difficult for the CBN cutting tool to form a retained layer or built-up edge when cutting.

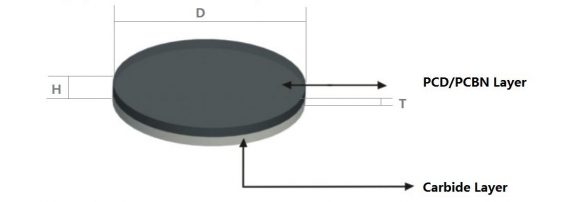

The Drawing:

Description:

PCBN Blank is characteristic of high hardness, high wear resistance and high thermal stability and is made by sintering micron CBN powder and various ceramic binders at a high temperature and pressure. BN series is composed of CBN layer and tungsten carbide base.

Halnn recommend cutting condition

CBN Concent(%) | Granularity(µm) | Characteristic | Typical Application | |

1 | 93 | 8-10 | High content CBN, large granularity and high thermal conductivity; meanwhile, the overall structure is of high hardness and wear resistance | Suitable for high-speed roughing of various ferrous metals with excellent processing performance |

2 | 85 | 6-8 | Good abrasion and impact resistance, excellent chemical wear resistance, fine grain structure and high toughness | Suitable for processing various types of materials, continuous and Semi-interrupt cutting of cast iron, hardened steel |

3 | 75 | 6-8 | Good abrasion and impact resistance, excellent chemical wear resistance, fine grain structure and high toughness | Suitable for processing a variety of powder metallurgy materials, suitable for the efficient processing of hardened steel with hardness above HRC45 (suitable for continuous, intermittent processing, and Roughing and Finishing can be used) |

4 | 50 | 1-2 | Low content CBN, small granularity, good abrasion resistance, impact resistance and chemical stability | When the ferrous metal material is continuously finished, it has good edge stability. Due to its high tool life and workpiece quality, it is suitable for all kinds of hard cutting and has excellent effects on continuous and semi-intermittent cutting. It is recommended for processing hardened steel |

In general, high content PCBN is used in cast iron applications while low content PCBN is used in hardened steel applications.

How to order?

Blank Specification | Diameter (D) | |

Thickness of Abrasive Layer (T) | ||

Total Height (H) | ||

Granularity(µm) | ||

Workpiece Info | Material | |

Request Finish(Ra/Rz) | ||

Cutting condition | Continuous/Intermittent | |

Large Feed/Small Feed |

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone