Full name: Turning Cast Iron CBN inserts, Solid CBN inserts

Machining Hardness Range: HRC35-HRC68

Machining Materials: high chromium cast iron, nickel hard cast iron, high nickel chromium alloy, chilled cast iron, white cast iron, gray cast iron, etc.;

Machining Type: Grinding instead of Turning, Roughing, Semi-Finishing and Finishing

Continuous and interrupted processing possible

Recommend cast iron CBN inserts

|  |  |  |  |  |

RNMN/RNGN | SNMN/SNGN | CNMN/CNGN | RCMX-V | RCGX-Y | SCGN |

|  |  | |||

TNGA | CNGA | WNGA |

Performance advantages:

High hardness;

Good wear resistance and chipping resistance;

Excellent impact resistance and fracture resistance;

High cutting efficiency and long tool life;

Application fields

Materials: high chromium cast iron, nickel hard cast iron, high nickel chromium alloy, chilled cast iron, white cast iron, gray cast iron, etc.;

Industries: Metallurgical Rolls, Cement building materials machinery, Power Equipment, automotive industry, Mining machinery etc.;

Workpieces: Slurry pump, Impeller, Roll, Liner, Cone Crusher, brake discs, brake drums, pulleys, air-conditioning compressors, etc.

Cutting Parameters

Machining material | Recommended cutting parameters | CBN insert Grade | ||

Cutting speed VC(m/min) | Cutting Depth ap (mm) | Feed Rate Fr(mm/r) | ||

High hardness cast iron (HRC35-68) | 35-120(Roughing) | 1-10 | 0.15-0.8 | BN-K1 |

60-180(Finishing) | ≤1 | 0.05-0.35 | ||

Grey cast iron | 400-1200(Roughing) | 1-10 | 0.2-1 | BN-S30, BN-S300 |

600-2000(Finishing) | ≤1 | 0.05-0.3 | ||

300-1500(Finishing) | ≤1 | 0.05-0.3 | BN-K20, BNK30 | |

Application cases

| Workpiece: Slurry pump body | ||

Material: Cr26(Hardness HRC60) | |||

Insert Type: BN-K1 CNMN120712 | |||

Cutting parameters: Vc=75m/min, Fr=0.12mm/r, ap=2.5mm | |||

Processing method: dry cutting | |||

Insert grade | Tool Life/edge | Failure mode | |

Halnn BN-K1 CBN inserts | 85pcs | Normal wear | |

Some brand CBN | 35pcs | Damage rupture | |

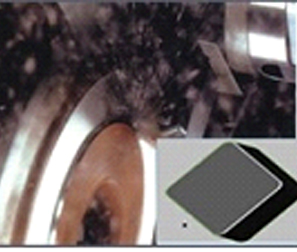

Workpiece: Slurry Pump impeller |  | ||

Materials: High chromium cast iron Cr26(Hardness HRC60) | |||

Insert Type:BN-K1 SNMN120712 | |||

Cutting parameters:Vc=75m/min, Fr=0.12mm/r, ap=2.5mm | |||

Processing method: Heavy Interrupt dry Turning | |||

Insert grade | Tool Life/edge | Failure mode | |

Halnn BN-K1 | 11pcs | Normal wear | |

Some brand CBN | 3pcs | Damage rupture | |

| Workpiece Material: High Chromium alloy cast iron | ||

Material: Cr26(Hardness HRC60) | |||

Insert Type: BN-K1 CNMN120712 | |||

Cutting parameters: Vc=75m/min, Fr=0.12mm/r, ap=2.5mm | |||

Processing method: dry cutting | |||

Insert grade | Cutting Width | Failure mode | |

Halnn BN-K1 | 500mm | Normal wear | |

Some brand CBN | 150mm | Damage rupture | |

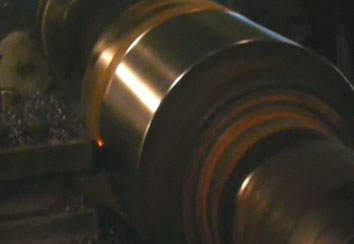

Workpiece: Rolls |  | ||

Materials: Chilled cast iron (Hardness HSD67) | |||

Insert Type:BN-K1 RNMN120400/CNMN1207 | |||

Cutting parameters:ap=2mm, Fr=0.5mm/r, Vc=66m/min | |||

Processing method: Dry Turning | |||

Insert grade | Efficiency | Life time | |

Halnn BN-K1 | Improved 2times | 3 times | |

Carbide Insert | / | / | |

| Workpiece: Brake drum | ||

Material: Gray cast iron | |||

Insert Type: BNK30 WNGA080408 | |||

Cutting parameters: Vc=650m/min, Fr=0.2mm/r, ap=0.5mm | |||

Processing method: dry cutting | |||

Insert grade | Tool Life/edge | Roughness | |

Halnn BNK30 | 120pcs | Ra1.6 | |

Some brand CBN | 70pcs | Ra2.0 | |

Workpiece: Bear of air conditioner compressor |  | ||

Material: Gray cast iron | |||

Insert Type: BNK30 WNGA080408 | |||

Cutting parameters: Vc=600m/min, Fr=0.25mm/r, ap=0.3mm | |||

Processing method: dry cutting | |||

Insert grade | Cutting Speed | Tool Life/edge | |

Halnn BNK30 | 600m/min | 500pcs | |

Coated carbide inserts | 330m/min | 80pcs | |

| Workpiece: Pulley | ||

Material: Gray cast iron | |||

Insert Type: BN-K20 CNGA120408 | |||

Cutting parameters: Vc=550-700m/min, Fr=0.25mm/r, ap=0.3mm | |||

Processing method: dry cutting | |||

Insert grade | Roughness | Tool Life/edge | |

Halnn BNK20 | Ra1.6 | 200pcs | |

Some brand CBN | Ra3.2 | 35pcs | |

Workpiece: Brake Disc |  | |||

Material: Gray cast iron | ||||

Insert Type: BN-S300 SCGN090408 | ||||

Cutting parameters: Vc=800m/min, Fr=0.2mm/r, ap=0.25mm | ||||

Processing method: dry cutting | ||||

Insert grade | Insert Type | Cutting Speed | Tool Life/edge | |

Halnn BN-S300 | SCGN090408 | 800m/min | 300pcs | |

Coated carbide inserts | CNMG120408 | 300m/min | 15pcs | |

| Workpiece: Brake Disc | |||

Material: Gray cast iron(HT250) | ||||

Hardness: HB170~210 | ||||

Insert Type: BN-S30 CNMN120712 | ||||

Cutting parameters: Vc=500m/min, Fr=0.55mm/r, ap=2mm | ||||

Processing method: dry cutting | ||||

Insert grade | Cutting Speed | Tool Life/edge | Efficiency | |

Halnn BN-S30 | 500m/min | 200pcs | Improved 1.8 times | |

Carbide Insert | 180m/min | 30pcs | ------ | |

Workpiece: Brake Drum |  | |||

Material: Gray cast iron(HT250) | ||||

Hardness: HB170~210 | ||||

Insert Type: BN-S30 CNMN120716 | ||||

Cutting parameters: Vc=380/min, Fr=0.65mm/r, ap=2.5mm | ||||

Processing method: dry cutting | ||||

Insert grade | Cutting Speed | Tool Life/edge | Efficiency | |

Halnn BN-S30 | 380m/min | 95pcs | Improved 1.5 times | |

Coated Carbide Insert | 150m/min | 15pcs | ------ | |

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone