Full name: Cast Iron Milling Carbide tools

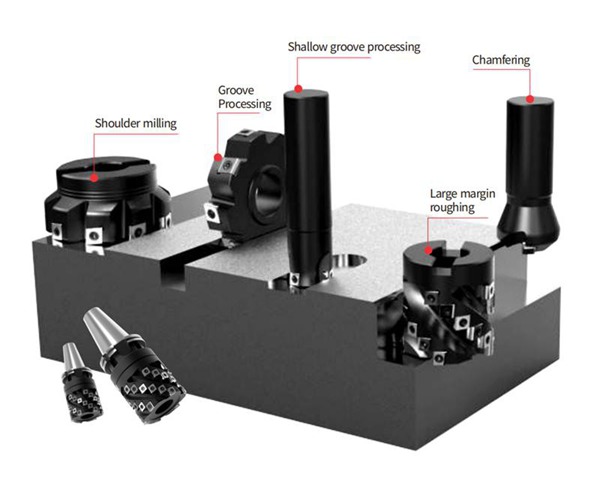

Product ranges: High-efficiency three-side milling tools, face milling cutter, corn milling cutter, etc.

Machining Type: Finishing, Semi-finishing, Roughing

In the realm of precision machining, selecting the right milling cutter is crucial to achieving optimal results. Cast iron, known for its durability and versatility, is a common material in manufacturing various components. Halnn, a leader in cutting tool technology, offers a comprehensive range of cast iron milling cutters designed to meet the high demands of modern machining processes.

Enhanced Precision and Surface Finish: Halnn’s milling cutters are designed to provide superior surface finishes and high dimensional accuracy, crucial for components requiring tight tolerances.

Increased Tool Life: The advanced materials and coatings used in Halnn’s cutters reduce wear and extend tool life, leading to lower tooling costs and fewer tool changes.

Improved Productivity: With high cutting speeds and efficient material removal rates, Halnn’s milling cutters enhance overall productivity and reduce machining time.

Versatility: Whether you’re dealing with pure cast iron or a combination of materials like cast iron and aluminum alloy, Halnn offers a milling cutter tailored to your specific needs.

1. Heavy-duty Milling: Halnn’s cast iron milling cutters are built to withstand the rigors of heavy-duty milling operations. They are designed with high strength and durability to handle the tough, abrasive nature of cast iron, ensuring long tool life and consistent performance.

2. High-efficiency Three-sided Milling Tool: Our high-efficiency three-sided milling tools are optimized for rapid material removal and high precision. These tools feature advanced geometries and coatings that reduce friction and heat buildup, allowing for faster cutting speeds and improved surface finishes.

3. Face Milling Cutter: Halnn’s face milling cutters are designed for superior surface finish and flatness. These cutters are ideal for large surface area machining, providing high metal removal rates and excellent dimensional accuracy.

4. Corn Milling Cutter: The corn milling cutter is another innovative solution from Halnn. Known for its unique cutting edge design, this cutter excels in high-speed machining applications, delivering high efficiency and reduced tool wear.

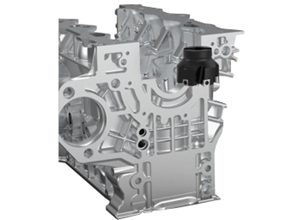

Workpiece: Cylinder block |  | |||

Material: Gray cast iron | ||||

Processing location: Bearing cap seat | ||||

In this application, Halnn's heavy-duty milling cutter was used to machine the bearing cap seat of a cylinder block. The cutter's robust design and advanced cutting technology ensured precise material removal and a superior surface finish, significantly enhancing the efficiency and accuracy of the machining process. | ||||

| Workpiece: Cylinder block | ||

Material: Cast iron + aluminum alloy | |||

Processing location: Camshaft cover opening | |||

For this case, a high-efficiency three-sided milling tool from Halnn was employed to machine the camshaft cover opening. The tool's ability to handle both cast iron and aluminum alloy materials with ease resulted in a seamless operation, achieving high precision and a clean finish across different material types. | |||

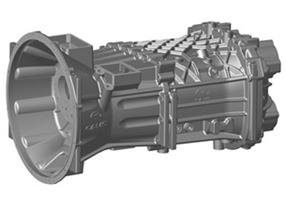

Workpiece: Gearbox housing |  | |||

Material: Cast iron | ||||

Processing location: Mounting surface | ||||

In this scenario, Halnn’s face milling cutter was utilized for machining the mounting surface of a gearbox housing. The cutter’s design ensured a flat, smooth surface with excellent dimensional accuracy. The high metal removal rate of the face milling cutter reduced cycle times and increased productivity. | ||||

Halnn's cast iron milling cutters are engineered to meet the highest standards of performance and reliability in the machining industry. By integrating our advanced milling cutters into your operations, you can achieve superior precision, increased efficiency, and extended tool life.

For more information about Halnn's cast iron milling cutters and how they can benefit your specific applications, please visit our website or contact our team of experts. Halnn is committed to providing cutting-edge solutions that drive the success of our customers in the competitive world of precision machining.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone