CBN Grinding Wheel is suitable for precise and high-speed grinding the camshaft, crankshatf, gear shaft and crankpin, main journal, flange neck, thrust face and end face.

CBN Grinding Wheel is suitable for precise and high-speed grinding the camshaft, crankshatf, gear shaft and crankpin, main journal, flange neck, thrust face and end face.

| Models | Spec. | |

| 1A1 | 1A1-D-T-H-X | |

| D | 200-750 | |

| T | 15-70 | |

| X | 3-10 | |

| 3A1 | 3A1-D*T*H*X | |

| D | 300-950 | |

| T | 5-10 | |

| X | 10-500 | |

| 14A1 | 14A1-D*T*H*X | |

| D | 300-950 | |

| T | 5-10 | |

| X | 10-500 | |

| We can also produce drawings according to customer requirement | ||

Why Choose Halnn's CBN Grinding Wheels?

Made from cubic boron nitride (CBN), our grinding wheels excel at machining hardened steel and cast iron, maintaining their cutting edge over prolonged use.

Halnn’s CBN grinding wheels ensure high accuracy, perfect surface finishes, and tight tolerances, essential for machining critical parts like camshafts and crankshafts.

Our grinding wheels are designed to resist thermal damage, ensuring stable performance during high-speed grinding operations.

The superior wear resistance of Halnn’s CBN wheels reduces tool replacement frequency, minimizing downtime and lowering operational costs.

We offer a range of wheel shapes, sizes, and specifications tailored to meet the specific needs of your camshaft and crankshaft grinding applications.

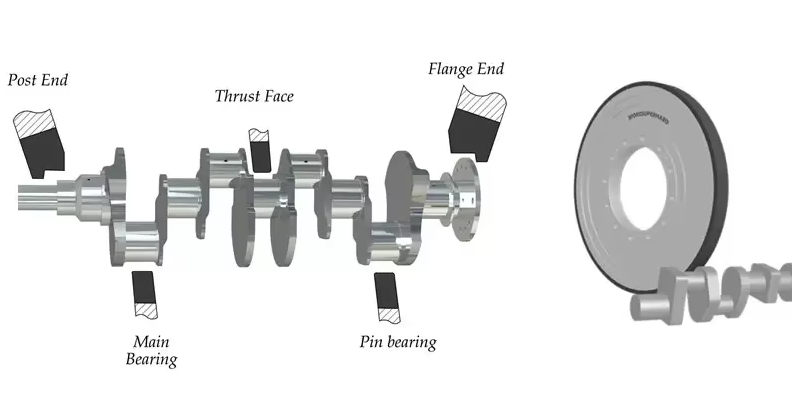

The main parts of the crankshaft to grind and regrind, include

► Main Bearing

► Rod Journals / Crankpin Journals

► Flywheel Flange End

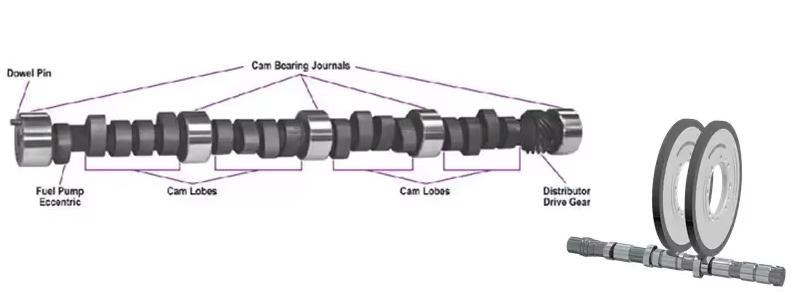

The main parts of the camshaft to grind and regrind, include

► Camshaft main journals

► Cam (fixed on shaft)

► Cams (single)

► Camshaft tube

Halnn’s CBN grinding wheels are specifically optimized for:

·Camshaft Grinding: Delivering precise profiles and superior surface finishes for performance-critical components.

·Crankshaft Grinding: Ensuring smooth, accurate machining of journals and main shafts to meet exacting industry standards.

·Automotive Industry: High-efficiency grinding of hardened steel components for engines and powertrains.

·General Engineering: Precision grinding of cast iron and alloy steel components.

Ready to enhance your grinding efficiency? Discover the unparalleled performance of Halnn’s CBN grinding wheels for camshaft and crankshaft machining. Contact us for technical support or to request a custom solution tailored to your specific needs.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone