Full Name: Mill Rolls Special Diamond inserts, Mill Roller CBN inserts

Machining Materials: Tungsten Carbide Inserts

Recommend Tools: PCD Notching Tools. PCD Engraving Tools, Arbor, Block, RCGX Solid CBN Inserts, RCGX PCD Inserts

Tungsten carbide Mill Rolls special PCD Tools

Tungsten Carbide Mill rolls ring (WC / TC Mill Rolls). The hardness can reach HRA78~95.

The process methods of Tungsten carbide Mill rolls are mainly turning and grinding, crescent milling (etching ribs), lettering.

For Turning,we recommend two materials tools to machining it. If the hardness of arbide rolls which hardness ≤ HRA88, use Solid CBN inserts is better.

If the hardness of Tungsten carbide tools > HRA 88, the PCD Tools is better.

The following are mainly the PCD inserts RCGX, PCD Notchining Tools, PCD Engraving tools, and Alock, Block. The CBN Inserts and other products please refer: https://www.halnn-group.com/Solution_mill_rolls_industry/

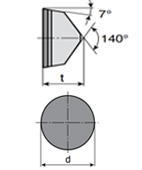

PCD Tools - RCGX V / Y type

Drawing | Type | Dimension | Picture | |||

L(mm) | φI.C(mm) | S(mm) | r(mm) | |||

| RCGX060300 V / Y | 6.35 | 3.18 |

| ||

RCGX060400 V / Y | 6.35 | 4.76 | ||||

RCGX060500 V / Y | 6.35 | 5.56 | ||||

RCGX060600 V / Y | 6.35 | 6.35 | ||||

RCGX090300 V / Y | 9.525 | 3.18 | ||||

RCGX090700 V / Y | 9.525 | 7.94 | ||||

RCGX120400 V / Y | 12.7 | 4.76 | ||||

RCGX120700 V / Y | 12.7 | 7.94 | ||||

RCGX151000 V / Y | 15.875 | 10 | ||||

RCGX191000 V / Y | 19.05 | 10 | ||||

PCD Notching Tools

Drawing | Order No. | Dimension(mm) | Picture | |||

φD | c | L | α | |||

| φ2*0.4*4.06*80° | 2 | 0.4 | 4.06 | 80 |

|

φ2.5*0.5*5.2*80° | 2.5 | 0.5 | 5.2 | 80 | ||

φ3.0*0.6*5.5*80° | 3 | 0.6 | 5.5 | 80 | ||

φ3.2*0.6*6.2*85° | 3.2 | 0.6 | 6.2 | 85 | ||

φ4.0*0.6*7.53*80° | 4 | 0.6 | 7.53 | 80 | ||

φ4.0*0.7*7.83*70° | 4 | 0.7 | 7.83 | 70 | ||

φ4.0*0.8*9.55*80° | 4 | 0.8 | 9.55 | 80 | ||

| φ4.0*0.7*7.98*80° | 4 | 0.7 | 7.98 | 80 |

|

φ4.0*0.8*9.68*80° | 4 | 0.8 | 9.68 | 80 | ||

φ4.0*0.9*10.8*80° | 4 | 0.9 | 10.8 | 80 | ||

φ5.0*0.7*7.5*80° | 5 | 0.7 | 7.5 | 80 | ||

φ6.0*0.9*9.0*80° | 6 | 0.8 | 9 | 80 | ||

φ7.0*0.8*11.0*80° | 7 | 0.8 | 11 | 80 | ||

φ8.0*0.8*12.0*80° | 8 | 0.8 | 12 | 80 | ||

PCD Engraving Tools

Drawing | Order No. | Shank D/ d1h7 | Length/ L | Angle/ Er | Width /B | Picture |

| φ6.0*50*70°*0.3 | 6 | 50 | 70 | 0.3 |

|

φ6.0*50*70°*0.5 | 6 | 50 | 70 | 0.5 | ||

φ6.0*50*90°*0.3 | 6 | 50 | 90 | 0.3 | ||

φ6.0*50*90°*0.5 | 6 | 50 | 90 | 0.5 | ||

φ8.0*50*70°*0.3 | 8 | 50 | 70 | 0.3 | ||

φ8.0*50*70°*0.5 | 8 | 50 | 70 | 0.5 | ||

φ8.0*50*90°*0.3 | 8 | 50 | 90 | 0.3 | ||

φ8.0*50*90°*0.5 | 8 | 50 | 90 | 0.5 |

Arbor / Holder / Spindle

Drawing | Order No. | Dimension(mm) | Picture | ||||

D1 | D2 | D3 | L1 | L2 | |||

| N4 | 4 | 2 | 16 | 4.06 | 35 |

|

N6 | 4.5 | 2.5 | 16 | 5.22 | 35 | ||

N8 | 5 | 3 | 16 | 5.5 | 37 | ||

N9 | 6 | 3 | 16 | 6 | 37 | ||

N10 | 6 | 3.2 | 16 | 6.8 | 41 | ||

N12 | 7.3 | 4 | 16 | 8 | 56 | ||

N13 | 8 | 4.5 | 16 | 9 | 56 | ||

N14 | 8.8 | 5 | 16 | 9.5 | 56 | ||

N16 | 10.4 | 5 | 18 | 11 | 65 | ||

N18 | 12 | 6 | 18 | 12 | 65 | ||

N20 | 13.5 | 6 | 18 | 14 | 65 | ||

N22 | 15.2 | 6 | 20 | 16 | 66 | ||

Block

Drawing | Type | R1 | R2 | R3 | R4 | Picture |

| 6# | 1.9 | 1.8 | 1.9 | 1.8 |

|

8# | 2.5 | 2.25 | 2.5 | 2.25 | ||

10# | 3 | 3 | 3 | 3.1 | ||

12# | 3.75 | 3.8 | 3.5 | 4.3 | ||

14# | 4.5 | 4.5 | 4.5 | 4.3 | ||

16# | 5 | 5.05 | 5 | 5.05 | ||

18# | 6 | 6 | 6 | 6 | ||

20# | 6.9 | 6.9 | 6.9 | 6.9 | ||

22# | 7.6 | 7.6 | 7.6 | 7.6 | ||

25# | 8.8 | 8.8 | 8.8 | 9 | ||

28# | 10.15 | 10.15 | 10.15 | 10.15 | ||

32# | 11.6 | 11.6 | 11.6 | 11.6 | ||

36# | 13.15 | 13 | 13.15 | 13.15 | ||

40# | 14.5 | 14.5 | 14.5 | 14.5 | ||

50# | 18.6 | 18.6 | 18.6 | 18.6 |

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone