Full Name: Bearing Special CBN/PCD Inserts

Using Inserts type: RNGN, RNMN, RCGX, TNGA, CNGA, DNGA,WNGA

Processing hardness: Above HRC45

Processing Material: Hardened steel, Bearing steel

Processing Way: Roughing, finishing

Continuous and Intermittent Cutting

hard Turning Slewing Bearing, CBN Insert Turning Bearing, PCBN inserts Recommend inserts

|

|

|

|

|

RNGN CBN inserts | RNMN CBN inserts | RCMX-V CBN inserts | RCMN CBN inserts | DNGA CBN inserts |

|

|

| ||

TNGA CBN inserts | CNGA CBN inserts | TNGA CBN inserts |

Advantages of our CBN inserts machining Bearing

High hardness

Excellent both abrasion resistance and impact resistance;

High cutting efficiency and long tool life;

Patented product, non-metal adhesive CBN inserts.

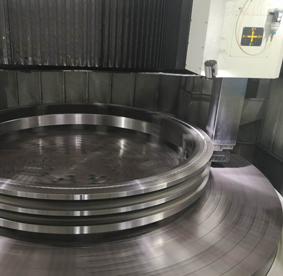

Processing case

Processing part: Wind power bearing, Inner Ring Rib |  |

Processing size: 2750mm | |

Material: 42CrMo4 | |

Hardness of Bearing: 58-63 HRC | |

Surface Roughing: Ra 0.4 | |

Inserts Type:BN-H200 RNGN090300 | |

Machining way:Roughing | |

Machining parameter:Vc=190m/min Fr=0.32mm/r, Ap=0.6-0.7mm | |

Machining way: Finishing | |

Machining parameter:Vc=215m/min,Fr=0.2mm/r,ap=0.2mm |

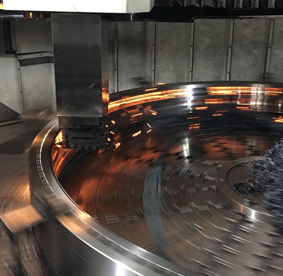

| Processing part: Wind power bearing, Outer Ring Raceway |

Processing size: 2750mm | |

Material: 42CrMo4 | |

Hardness of Bearing: 58-63 HRC | |

Inserts Type:BN-H200 RNGN090300 | |

Machining way:Roughing | |

Machining parameter:Vc=190m/min, Fr=0.43mm/r, Ap=1mm | |

Machining way: Finishing | |

Machining parameter:Vc=260m/min,Fr=0.2mm/r,ap=0.1mm |

Heat-treated bearings, such as wind turbine bearings, metallurgical bearings, and wheel hub bearing units, generally have a hardness above HRC50, which puts high demands on the wear resistance and life of the tool.

Large-scale bearings, such as wind turbine bearings, have large diameters. After heat treatment, the machining allowance is 2-6mm, and the machining allowance is uneven. Moreover, there are oil holes in the lunar groove of the outer ring raceway of the machining part. The tool needs good impact resistance and toughness. It will break easily. At the same time, bearings have higher requirements for accuracy and surface roughness. For example, the accuracy tolerance of the raceway radian of the wind turbine bearing is 0.08, and the surface roughness of the raceway is Ra0.4.

With the continuous development of the modern tool industry, the cubic boron nitride (CBN) tool BN-H200 material developed by the superhard material industry effectively solves the problem of difficult bearing machining and can meet the requirements of high quality, high efficiency and low cost at the same time.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone