Halnn offers high-performance PCD guide bar reamers and customized hole-making tools designed for ultra-precision machining applications.

Halnn offers high-performance PCD guide bar reamers and customized hole-making tools designed for ultra-precision machining applications. Whether you're dealing with hard-to-machine materials, tight tolerance requirements, or high-volume production lines, our PCD (Polycrystalline Diamond) tools deliver exceptional dimensional accuracy, long tool life, and reduced cycle times.

From standard guide bar reamers to complex multi-step and custom hole-finishing tools, Halnn provides tailor-made solutions based on your specific application and machining conditions.

The guide bar reamer utilizes a dedicated guide bar section that provides precise support and alignment during the reaming process. This design ensures that the tool maintains concentricity and avoids deflection, enabling ultra-high precision hole finishing.

A key feature of the guide bar reamer is the thin oil film lubrication formed between the guide bar and the workpiece surface. This oil film minimizes friction and protects the processed surface from damage, ensuring a smooth, burr-free finish.

By incorporating ultra-high-precision ground PCD inserts and a μ-level adjustment mechanism, the guide bar reamer delivers exceptional dimensional accuracy and surface quality—often achieving the required hole tolerance from the very first part processed.

Halnn specializes in developing custom hole-making tools for specific parts, materials, and machining environments. We offer:

·Custom PCD step reamers

·PCD combination tools (drill + reamer)

·Guide bar and piloted reamers

·Helical PCD reamers for better chip evacuation

·Reamers with through-tool coolant options

·Custom cutting edge geometries for burr-free finishes

Every tool is designed to improve accuracy, reduce the number of tool changes, and optimize production efficiency.

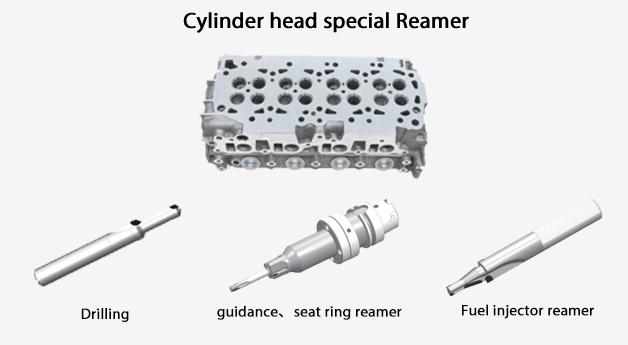

(1)Automotive cylinder head

(2)Automotive hydraulic parts: AT valve body, regulator valve body

(3)Steering spool, transmission housing

(4)Other aluminium alloy parts

(5)CFRP,Ceramic containing composite materials such as MMC

(1)With super high hardness and super wear resistance;

(2)Stable performance and long tool life;

(3)High processing efficiency and low cost;

(4)Higher surface finish can be obtained.

(5)High conductivity and good toughness

·Over 20 Years of Superhard Tool Expertise

We understand complex machining challenges and deliver solutions that work.

·In-House R&D & Manufacturing

From concept to finished product, all designs are optimized and tested in-house.

·Fast Turnaround & Reliable Support

Whether you need prototypes or large-scale production tools, we ensure timely delivery and technical assistance.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone