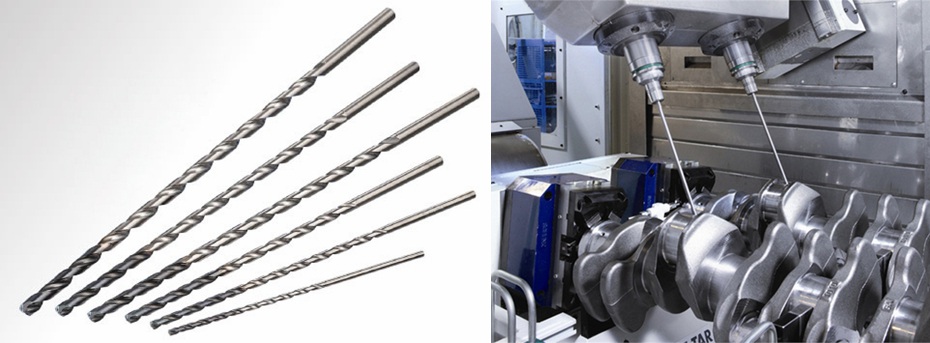

Halnn HD4060 deep hole drills are designed for machining success. For steel, cast iron, stainless steel, high-temp alloys, and more.

·Processing Diameter range: 12D-50D.

·Effective drilling depth: 400mm.

It is a cost-effective solution for drilling many materials.

Halnn offers high-performance solid deep hole drills designed for exceptional precision, long tool life, and efficient chip evacuation—making them ideal for drilling deep and narrow holes in hardened materials. Our solid deep hole drills are crafted using ultra-fine carbide materials and advanced geometries to ensure smooth, accurate machining even under the most demanding industrial conditions.

With a strong focus on innovation and customer-oriented solutions, Halnn delivers cutting tools that improve productivity and reduce machining costs across industries.

·Processing diameter range: 12D-50D

·Effective drilling depth: 400mm

Supports drilling with diameter-to-depth ratios ranging from 12D to 50D, making it ideal for deep hole machining.

Capable of drilling depths up to 400mm, ensuring flexibility for various machining requirements.

Designed to provide long tool life and consistent performance, reducing downtime and tooling costs.

Optimized cutting geometry for enhanced chip evacuation and minimized heat generation.

Internal coolant channels ensure effective cooling and lubrication, improving tool life and hole quality.

|  |  |

Harden® HD·12×D | Harden® HD·15×D | Harden® HD·20×D |

|  |  |

Harden® HD·25×D | Harden® HD·30×D | Harden® HD·40×D |

| Workpiece: crankshaft Hardness: HRC28-32 Workpiece material: 42CrMo Drilling depth: 150mm Machine: vertical machining center Drilling method: continuous machining | ||

| Comparison test | Original inserts | Halnn inserts | |

| Diameter | D8 internal coolant deep hole drill | D8 internal coolant deep hole drill | |

Vc(m/min) | 62.8m/min | 62.8m/min | |

F(mm/min) | 500mm/min | 500mm/min | |

| n(r/min) | 2500r/min | 2500r/min | |

| Processed Quantity | 180 pcs | 220 pcs | |

| Results: Under the same processing parameters, the life of Halnn's insert increased by 22%. | |||

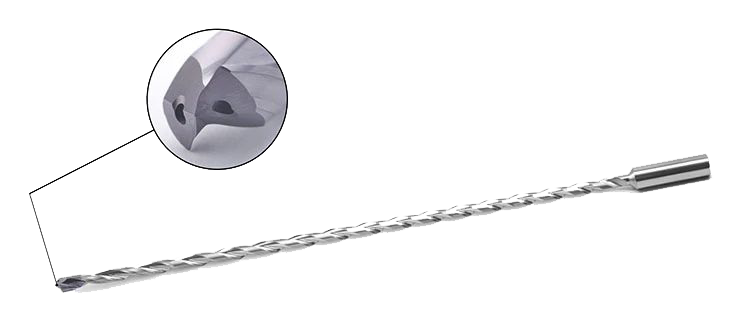

1. Optimized Chip Breaker & Rake Angle Design: A unique flute geometry and specialized core taper ensure smooth and efficient chip breaking and evacuation.

2. Special Drill Tip & Cutting Edge Design: The optimized point angle and positive rake angle at the chisel edge enhance centering accuracy, reduce cutting

resistance, and promote the formation of easily breakable conical spiral chips, significantly improving chip control.

3. Large Flute Opening & Four-Flute Guide Design: Provides enhanced cutting stability and reduced cutting resistance, ensuring a smoother drilling process.

4. High-Feed Rate Design: Allows for significantly improved processing efficiency, reducing overall machining time.

5. Advanced Manufacturing Process: Utilizing imported machine tools with P-axis configuration and full-length tool support ensures the reliability and precision required for producing 40:1 aspect ratio deep-hole drills.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone