Full name: Boring/Grooving Cast iron CBN inserts

Machining Hardness: Above HRC45

Machining Materials: High-alloy cast iron, iron-based sintered metal, chilled cast iron

Machining Type: Finishing

CBN Grooving Tools, CBN Grooving inserts, CBN cutter Recommend inserts

|  |  |  |  |  |

CNGA | TNGA | WNGA | TCGW | CCGW | MGGN |

| |||||

MRGN |

Performance advantages:

High hardness;

Good abrasion resistance and high-temperature resistance;

Can realize high-speed cutting

The processed workpiece has a high finish

Non-standard/CNC CBN tools can be customized

Application fields

Material: high chromium cast iron, high chromium anti-wear white cast iron, etc.;

Industries: automotive, medical, valve, and other industries;

Workpiece: Cylinder liner, hip joint support cover, valve seat, valve body, etc.

Cutting Parameters

Machining material | Recommended cutting parameters | CBN insert Grade | ||

Cutting speed VC(m/min) | Cutting Depth Ap (mm) | Feed Rate Fr(mm/r) | ||

Cast Iron | 100-280(Finishing) | ≤0.3 | 0.05-0.35 | BN-K10, BN-H50 |

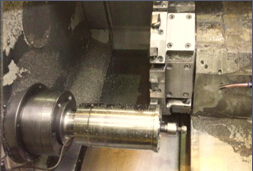

Application case

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone