Full name: PCBN Inserts, PCBN Turning/Cutting inserts, Polycrystalline cubic boron nitride inserts

Machining Type: Finishing, Semi-finishing

Machining Hardness: Above HRC45

Machining Materials: Hardened steel material, Gray cast iron, etc.

Continuous and intermittent machining

Halnn brazed PCBN Inserts ISO Types

|  |  |  |  |  |

CNGA-4S | DNGA-4S | TNGA-6S | WNGA-6S | VNGA-4S | SNGA-4S |

|  |  | |||

CCGW-2S | TCGW-3S | VCGW-2S |

Halnn PCBN Inserts ISO Types

|  |  |  |  |  |

CNGA-2S | SNGA-2S | TNGA-3S | DNGA-2S | WNGA-3S | CNGA-4S |

|  |  |  |  |  |

SNGA-4S | TNGA-6S | DNGA-4S | WNGA-6S | DCGW-1S | TPGN-1S |

|  |  |  |  |  |

VNGA-2S | VBGW-2S | TCGW-3S | DCGW-2S | CCGW-2S | VNGA-4S |

|  |  |  |  | |

VCGW-2S | SPGN-1S | TPGW-3S | Coating PCBN | Coating PCBN |

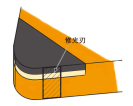

Halnn CBN Inserts with Chipbreaker

Excellent chip breaking performance, avoid chip winding the workpieces or the tool, ensuring good surface quality and the tool life.

Without Chipbreaker With Chipbreaker

Different chips with same cutting condition by CBN inserts with or without chipbreaker

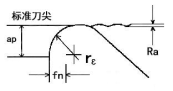

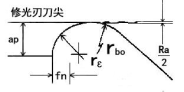

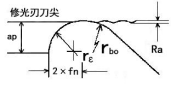

Halnn CBN Insert with Wiper

With same feed, obtain higher surface quality.

With same roughness, can be used for large feed, reduce the time on each component, improve the process efficiency.

Note: It can be used for Profile machining, suit for the CNC Lathe with high rigidity.

Wiper Common Tip Wiper Tip(High Surface Quality) Wiper Tip(High Feed,High Efficiency)

Halnn PCBN Inserts Cutting Parameters for reference

Machining Materials | Machining Type | Recommended cutting parameters | CBN insert Grade | ||

Cutting speed VC(m/min) | Cutting Depth ap (mm) | Feed Rate Fr(mm/r) | |||

High hardness cast iron (Hardness: HRC35-68) | Finishing | 60-200 | ≤1 | 0.05-0.35 | BN-K10, BN-H10 |

Hardened steel (Hardness≥HRC45) | Finishing | 90-250 | ≤1 | 0.05-0.35 | BN-H20, BN-H11, BN-H05, BN-H10, BN-H21 |

Grey cast iron | Finishing | 600-2000 | ≤1 | 0.05-0.3 | BNK30, BN-K20, BN-K10 |

Halnn PCBN Inserts Grade

Insert Grade | Suited Materials | Machining Type | Typical Applications |

BN-H11 | Hardened Steel | Semi-Finishing, Finishing | Bearings, Gears, Gear Shaft, Hardened Mold |

BN-H20 | Hardened steel, other materials of difficult to machine | Semi-Finishing, Finishing | Hardened Steel Gears, Mold,ect |

BN-K20 | Gray cast iron | Semi-Finishing, Finishing | Brake Disc, Cast Iron Engine,Gearbox |

BNK30 | Gray cast iron, Iron-based alloy | Semi-Finishing, Finishing | Brake Disc, Brake Drum, Cast Iron Engine, Gearbox |

BN-H05 | Hardened Steel | Finishing | Gears, Gear Shaft, Bearings |

BN-H10 | Hardened Steel, high strength cast iron | Finishing | Bearings, Gears, Gear Shaft, High hardness component |

BN-K50 | Powder Metallurgy | Finishing | Powder Metallurgy Valve seat |

BN-H21 | Hardened Steel | Finishing | Bearings, Gears, Gear Shaft, Mold,ect. |

BN-K10 | Gray Cast Iron, Powder Metallurgical | Finishing | Valve seat ring; Engine cylinder bore; Powder Metallurgy parts |

BN-H05 C25 | Hardened Steel | Finishing | Bearings, Gears, Gear Shaft, Mold, ect |

BN-H10 C25 | Hardened Steel | Finishing | Bearings, Gears, Gear Shaft, High hardness components |

BN-H21 C25 | Hardened Steel | Finishing | Bearings, Gears, Gear Shaft, Mold, ect |

Halnn PCBN Inserts Characteristics

Insert Grade | Binder | CBN Content(%) | Granularity(μm) | Hardness(HV) |

BN-H05 | TIN | 45 | ≤1 | 2700-2800 |

BN-H10 | TIN | 50 | ≤1 | 2700-2800 |

BN-H21 | AL, TINC | 60 | 1-2 | 2600-2800 |

BN-K10 | Ti, Co | 95 | ≤2 | 3300-3500 |

BN-K50 | Co | 85 | ≤2 | 3300-3500 |

BN-H11 | TIN | 70 | 2-4 | 2800-3000 |

BN-H20 | TIC | 80 | 2-4 | 3100-3300 |

BN-K20 | TIC | 95 | 2-4 | 3400-3600 |

BNK30 | Si, TIC | 97 | 2-4 | 3400-3600 |

Halnn PCBN Inserts Cutting Conditions

CBN Content | Insert Grade | Cutting Depth | Condition |

High Content | BNK30 | ≤1.5mm | Continuous |

BN-K50 | ≤0.5mm | Continuous | |

BN-K10 | ≤0.5mm | Continuous | |

Low Content | BN-H20 | ≤1mm | Semi-Interrupt |

BN-H11 | ≤1mm | Continuous | |

BN-H05 | ≤0.2mm | Continuous | |

BN-H10 | ≤0.5mm | Continuous~Semi-Interrupt | |

BN-H21 | ≤0.5mm | Semi-Interrupt~Heavy Interrupt | |

BN-H05 C25 | ≤0.2mm | Continuous | |

BN-H10 C25 | ≤0.5mm | Continuous~Semi-Interrupt | |

BN-H21 C25 | ≤0.5mm | Semi-Interrupt~Heavy Interrupt |

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone