Description: Hard Milling/ Turning of Ball Cage / CV Joint special Tools

Using Inserts type: TNGA, CNGA, DNGA, PCBN Milling Tools, Diamond Dressing Wheel

Processing parts:Spherical shell, star sleeve, etc

Processing Material: Hardened steel

Processing Way: Roughing, finishing;

Continuous and Intermittent Process

CV joint hard milling, CBN Turning CV Joint Recommend nserts

|

|

|

|

|

CBN Milling Tools | Diamond Dressing Wheel | CNGA CBN inserts | TNGA CBN inserts | DNGA CBN inserts |

Halnn Tools advantages

Tools have reasonable structure design, diversified and refined cutting edge processing;

Tools have long life, reduce the number of tool changes, improve processing efficiency, and reduce tool and labor costs;

Indexable CNC inserts, high machining accuracy, reduce tool setting time and improve efficiency;

Good wear resistance, can meet high-speed cutting, save time and reduce processing costs

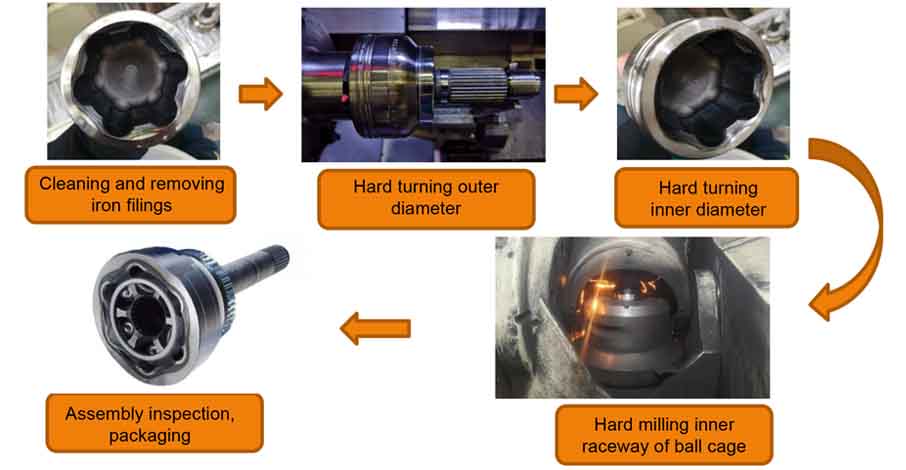

Hard turning process of outer ball cage

Cage, also called "CV joint", is an important part of the car's transmission system. Its function is to transfer the power of the engine from the transmission to the driving wheels to drive the car at high speed.

There are many types of CV joints used in cars, among which the most widely used are the ball cage type CV joint and the tripod type CV joint, mainly including sliding sleeves, three-way shafts, drive shafts, and star sleeves. , The main parts of the cage and the bell-shaped shell.

Outer ball cage: The steel balls of this ball cage are fixedly placed in the six windows of a cage between the star sleeve and the bell shell. The steel balls in the star sleeve and the bell shell have exactly half each To determine the angle of action with the universal joint at one time, the smooth surface treatment makes the universal joint move like a helical gear. The six steel balls push the respective star sleeve and the ball path in the bell shell. It's just that the torque is transmitted through the steel balls instead of the teeth of the gears.

Application Cases

Processing part: outer diameter of outer ball cage (total three parts) Processing size: ø31.445, ø68, ø87.1 Workpiece material: Hardness steel Workpiece hardness: HRC58-63 Processing procedure: finishing Model: BN-H10 C25 (4165) CNGA120408S0015-4S (adding a Wipert) Processing parameters: ø31.445 Vc=140m/min, S=1447, Fr=0.35 ø68 Vc=172m/min, S=843, Fr=0.35 ø87.1 Vc=146m/min , S=534, Fr=0.45 |

|

| Hardness:HRC60 CV Joint Processing procedure: Finishing Tool model: BN-H10 TNGA160408 Cutting parameters: Vc=190m/min, Fr=0.15mm/r, Ap=0.15mm Processing method: dry cutting | ||

Inserts | Vc | Tools life | |

Halnn BN-H10 | 190m/min | 370 pcs/tip | |

Other CBN inserts | 170m/min | 355 pcs/tip | |

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone