Special deep hole drill and supporting inserts for special steel/tank/petroleum machinery parts

Indexable Gun Drill

Carbide Gun Drill

Brazed Gun Drill

Solid Carbide Gun Drill

A gun drill, also known as a deep hole drill, is a specialized tool designed for high-precision drilling, capable of producing deep holes with a diameter-to-length ratio of up to 1:250. The gun drill consists of three main components: the drill head, drill shaft, and drill shank, all of which are brazed together. The tool is characterized by a V-shaped flute for external chip evacuation, a critical feature that ensures the efficient removal of chips during deep hole drilling.

Halnn provides various gun drills & deep hole drills and customized drilling solutions according to your actual requirements. View our wide variety of deep hole gun drilling tools.

|  |  |  |

Carbide brazed gundrill | Carbide gun drills | Carbide tip gun drills | Gun drills |

|  |  |  |

Brazed gun drills | Indexable gun drill | Indexable gun drills | Solid carbide gun drill |

Gun drills are available in various designs, each optimized for specific applications. Halnn offers a comprehensive range of gun drills, including indexable, carbide, brazed, and solid carbide gun drills, each with distinct advantages.

Structure: Made entirely of solid carbide, including both the drill head and shaft.

Advantages:Offers superior rigidity and reduced vibration, resulting in higher cutting reliability and extended tool life. Solid carbide gun drills are especially effective in high-strength materials and applications requiring ultra-precision.

Applications: Best suited for high-precision applications such as medical device manufacturing, aerospace, and high-performance automotive components.

Specifications

|  |

Structure: Composed of a carbide drill head brazed to a steel shank.

Advantages: Carbide gun drills are the most common, offering a balance between cost and performance. They are known for their durability and are suitable for a wide range of materials.

Applications: Ideal for general-purpose deep hole drilling in materials like cast iron, aluminum, and steel.

Specifications

|  |

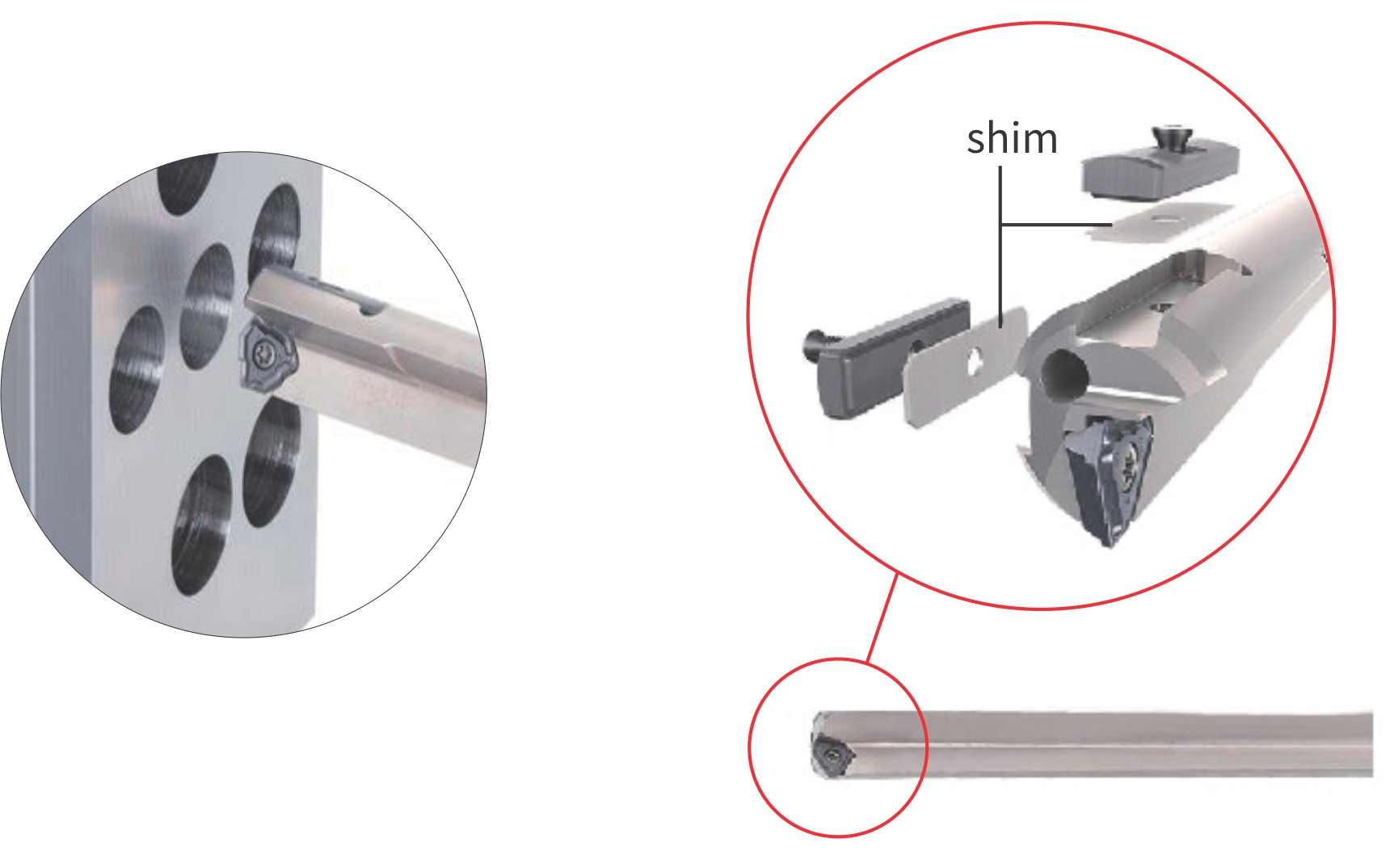

Structure: Features a modular design with replaceable carbide inserts and guide pads.

Advantages: Ideal for large-diameter holes (above 12mm), the indexable gun drill allows for quick insert changes, minimizing downtime. The indexable design enhances cutting efficiency, making it suitable for high-speed machining.

Applications: Used in automotive, aerospace, and heavy machinery industries.

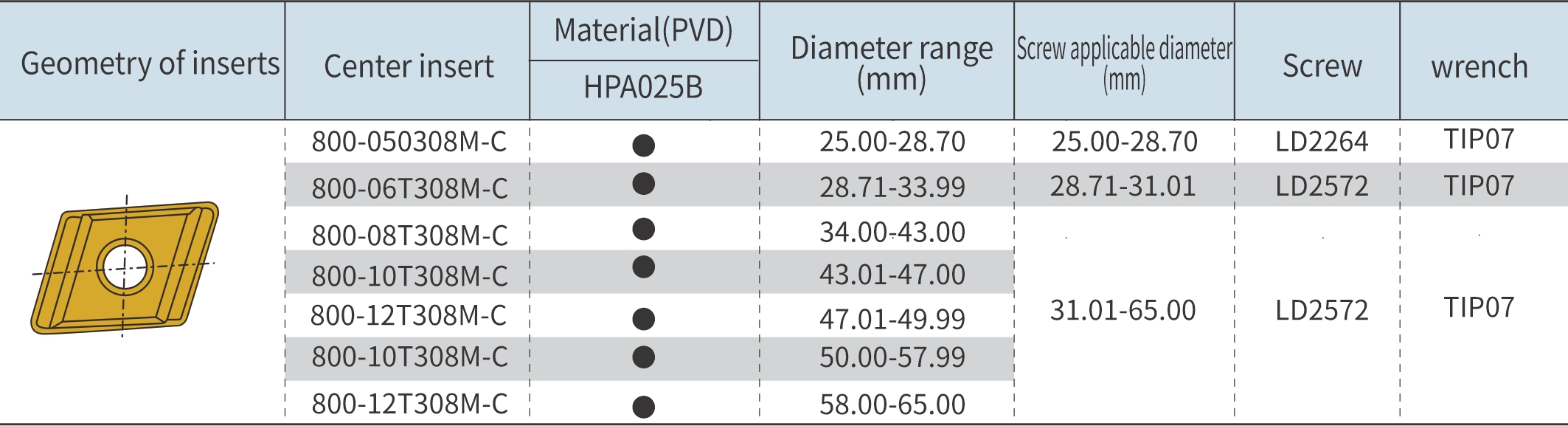

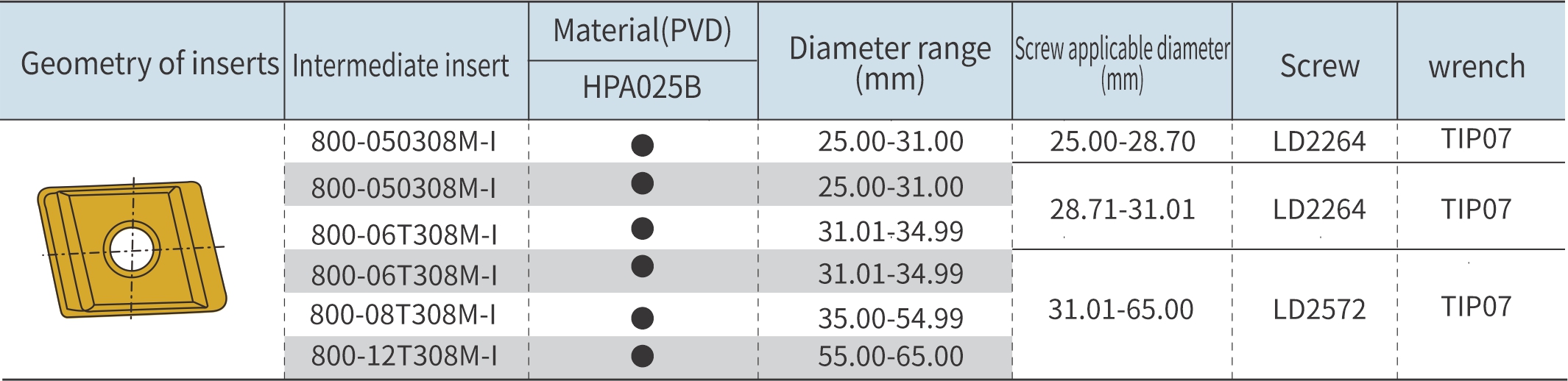

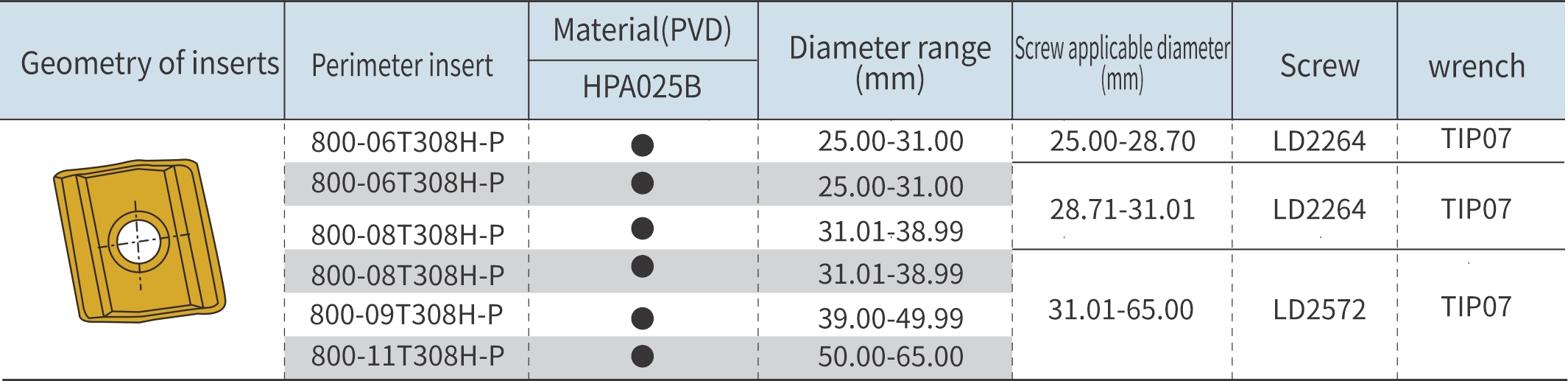

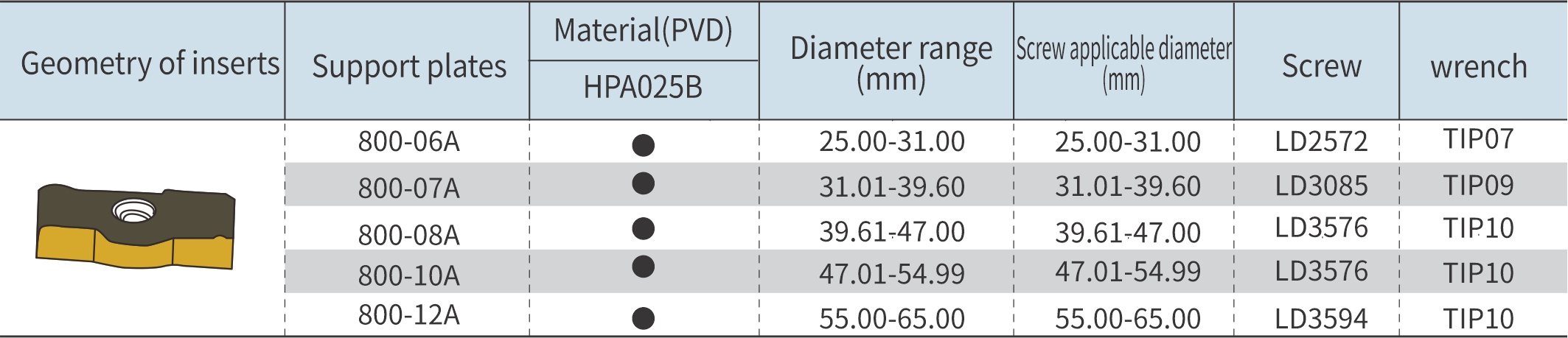

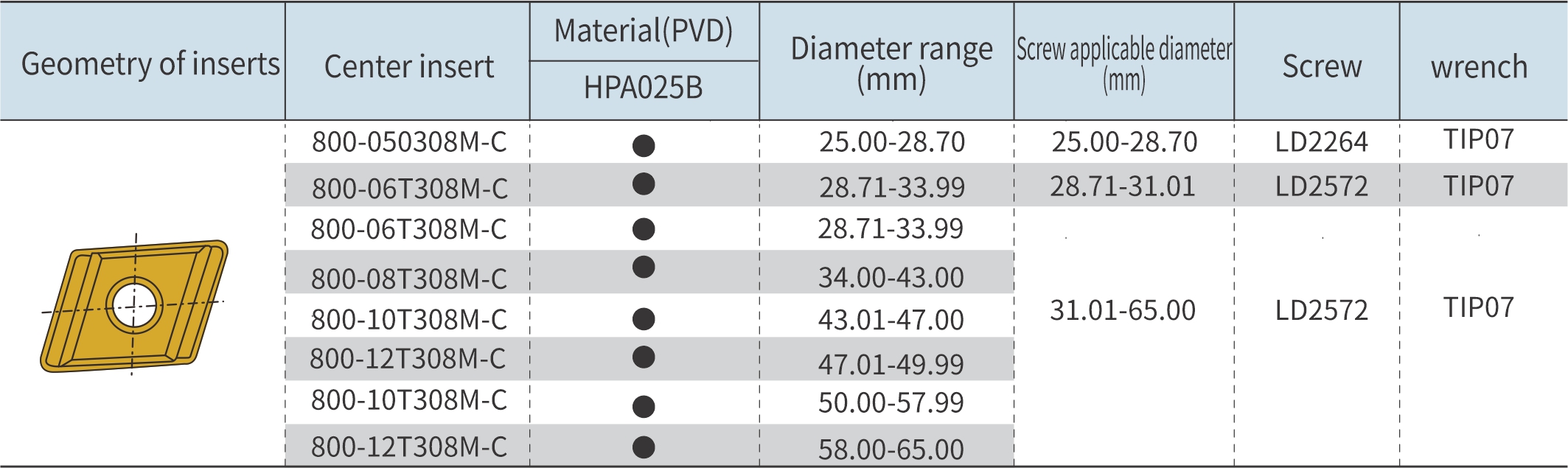

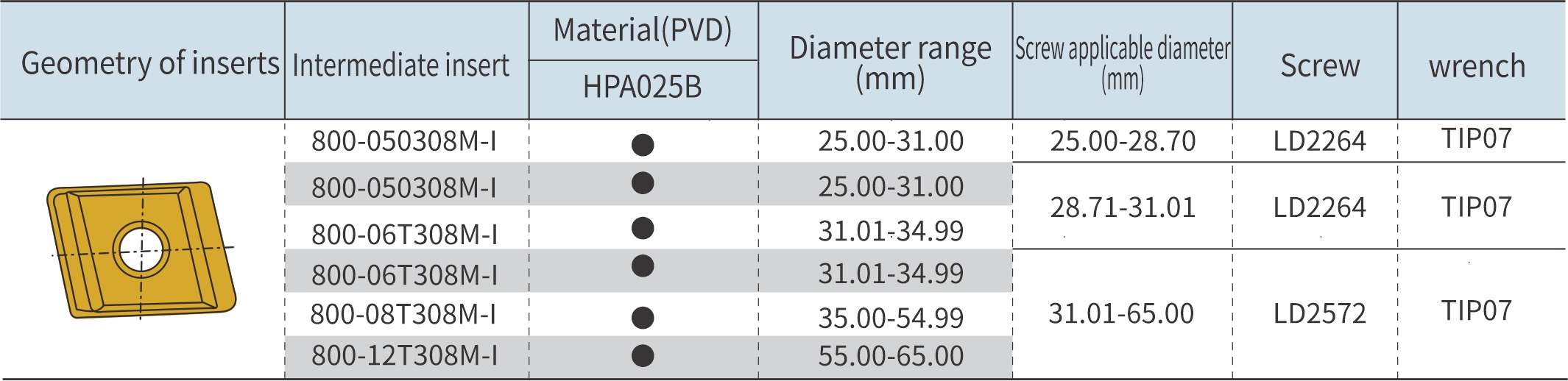

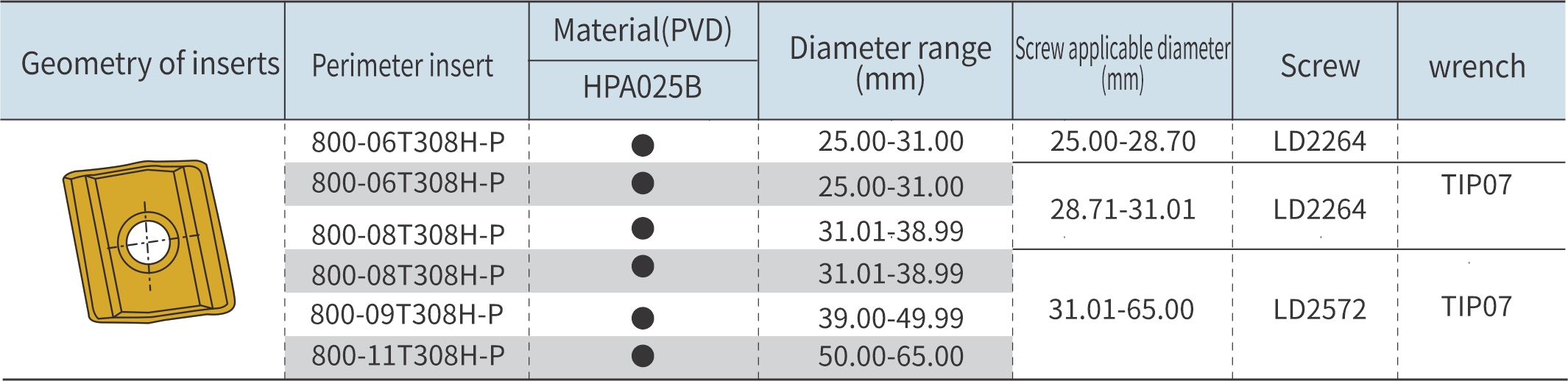

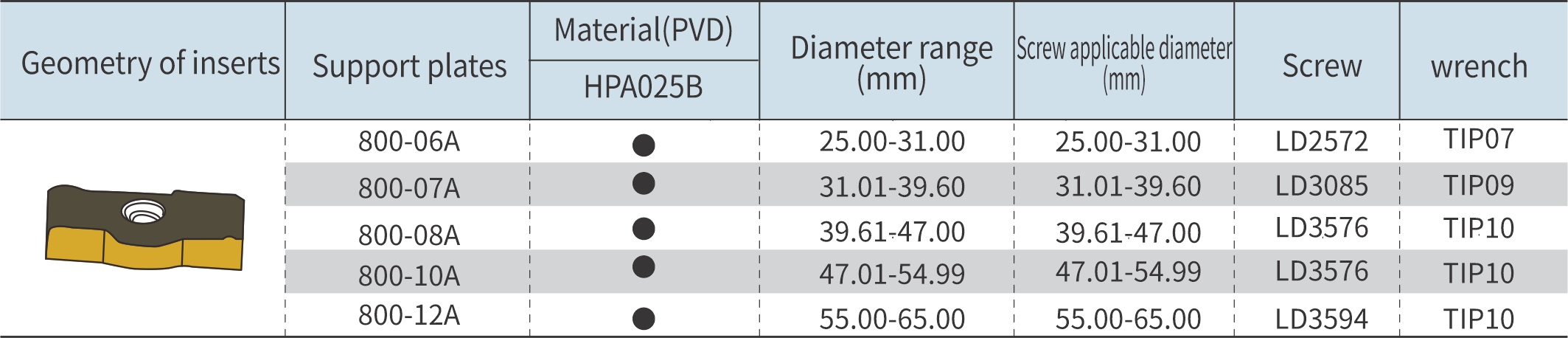

Specifications

|  |

Gun drills offer numerous advantages over conventional drilling methods, particularly in deep hole drilling scenarios. Here’s why Halnn’s gun drills stand out:

Gun drills are designed to produce holes with exceptional accuracy, meeting tight tolerances and ensuring consistent results.

The V-shaped flute design allows for efficient external chip evacuation, preventing blockages and reducing the risk of tool failure.

High-quality materials and advanced manufacturing processes extend the life of Halnn’s gun drills, reducing the need for frequent replacements.

Suitable for a wide range of materials and applications, from soft metals like aluminum to hard alloys used in aerospace.

Product feature

Compare to welding gun drill

1. The feed can be increased by 2.5 times to achieve higher production efficiency.

2. Special coating insert with 3-corners cutting edge fits with coated guide bar, to achieve higher tool life.

Compare to carbide drill

1. Better chip breaking effect, achieve good chip removal.

2. Ensure good hole straightness and surface roughness.

3. Insert replaceable, reduce cost.

4. Without tools regrinding, reduce management costs.

Product application

The deep hole processing

Diameter of tool: Φ12- Φ40mm

Hole roughness:<Ra2

Processing depth: Meet customer requirements

Applicable equipment: lathe, CNC, gun drill machine

Application: mould, automotive, heavy industry, power generation and other fields

Special deep hole drill and supporting inserts for special steel/tank/petroleum machinery parts

Accept OEM customization

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone