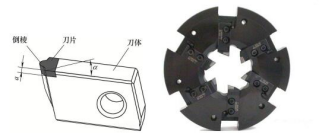

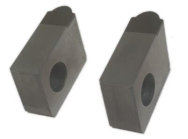

Full Name: Ball Screw Special Inserts CBN Inserts

Using Inserts type: CNGN, V- Grooving Tools(CBN Grooving Inserts)

Processing hardness: Above HRC45

Processing Material: Hardened steel, High Hardness Steel

Processing Way: Roughing, finishing;

Continuous and Intermittent Cutting

Advantages of Halnn CBN inserts BN-S20 and BN-H10 hard turning ball screws

(1) High hardness, abrasive resistance and heat resistance

(2) Strong impact resistance, avoid the insert chipping, damage problem

(3) High speed cutting, improve the efficiency

(4) Dry cutting method reduce the pollution

(5) Long tool life, will be 1.5~2 times of traditional CBN inserts.

Recommend CBN milling inserts-Ball screw special milling inserts

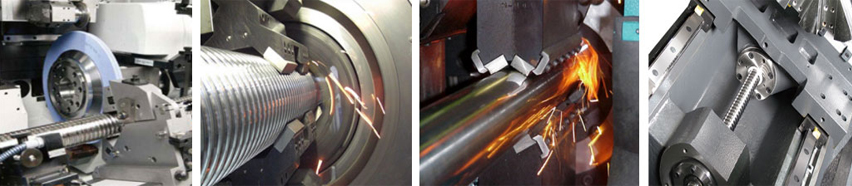

Application Cases

| Materials and Hardness :Rolling Screw Gcr15, HRC60-62 | |||

Selected Insert:BN-S20 CNGN120708 | ||||

Cutting Parameters:ap=4.5mm,Fr=0.10mm/r,Vc=95m/min, | ||||

Dry Cutting | ||||

Insert Materials | Cutting Speed | Cutting Depth | Failure Mode | |

Halnn BN-S20 | 95m/min | 4.5mm | Normal Wear | |

Ceramic Insert | 65m/min | 0.5mm | Broken Damage | |

Workpice and Hardness : Ball Screw Thread, Gcr15, HRC60-62 |

| ||

Selected Insert: BN-H10 CBN Grooving Inserts | |||

Cutting Condition: Fr=0.10mm/r, Vc=150m/min | |||

Dry cutting | |||

Insert Materials | Roughness | Failure Mode | |

Halnn BN-H10 | ≤Ra0.8 | Normal Wear | |

Other PCBN | Ra1.2-1.6 | Damage or Broken | |

With the development of the cutting technology, the cutting tools manufacturers researched new tool materials “cubic boron nitride” which can be use for turning instead of grinding, it will have Compressive stress when with traditional CBN inserts roughing the ball screw raceway, it will be easily make the insert chipping. Finally Halnn research non-metal adhesive solid CBN inserts BN-S20, solving the problems of chipping.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone