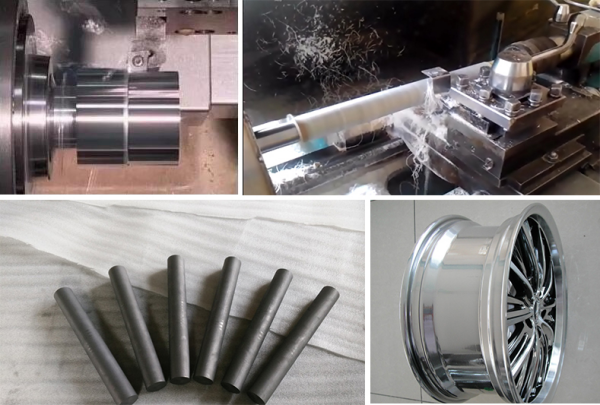

Full name: PCD Turning / Milling /Boring inserts, PCD tools, pcd cutting inserts

Process way: Turning, Milling, Boring

Process material: Nonferrous Metals and various difficult to process materials

Hot sales types: CCGW, DCGW, VCGW, TCGW, TPGW

PCD Turning / Boring inserts

|

|

|

|

|

|

CCGW | CCGT | CNGA | DCGT | DCGW | DNGA |

|  |  |  |  |  |

SCGT | SCGW | SNGA | SPGW | TCGT | TCGW |

|  |  |  |

|

|

TNGA | VBGT | VCGT | VCGW | WNGA | CCGW Hs |

|

| ||||

TCGW HS | TPGN HS |

PCD Milling inserts

|  |

|  |  |  |

RNGN | WCGW | APKT | RCGW/RPGW | PCD Notching Tools | PCD Notching Tools |

|

|

|

|

|

|

Customized PCD Milling Tools | |||||

PCD Chip breaker inserts

1) Inserts

|  |  | |||

VCGT | RCGT | TCGT |

2) Choosing the suitable PCD Chipbreaker inserts

Type | Finishing or Roughing | Advantages | Process Parameter | Chip Breaker |

FS | Finishing | General chip breaker geometry in the light cutting range, effectively reducing cutting resistance | Fr= 0.1 - 0.2mm/r; |

|

FM | Semi - finishing | Can maintain low cutting force, good chip breaking. | Fr= 0.15 - 0.3mm/r; |

|

FL | Roughing | Suitable for continuous and interrupted machining of aluminum alloys | Fr= 0.25 - 0.4mm/r; |

|

PCD Grade and Machining Characteristics

Grade | Grain size (μm) | Feature | Application |

CDW005 | 5μm -10μm | Excellent electric spark, good toughness, high wear resistance and high impact resistance. | PMMA, Silicon alloy and metal phone shell outline, wood, saws industry, Engrave milling Tools and thread tool, woodworking saws, particleboard ,silicon aluminum alloy |

CDW010 | 10μm | Universal PCD Grade, good toughness and high abrasive resistance | Finish for rough machining wood, molding, medium and low silicon aluminum alloy parts, Aluminum based silicon carbide |

CDW025 | 25μm | Excellent wear resistance, edge quality and high impact resistance | High Silicon Aluminum alloy, MMC, Tungsten carbide and ceramic, graphite,wear resistant parts, Wood finishing insert and saws |

CDW302 | 2 - 30μm | Excellent wear resistance, high thermal stability, high impact resistance and edges strength | High silicon aluminum alloy, composite plastic, duplex metal, metal matrix composite material, ceramic, etc. |

Component Materials | Component Materials | Vc (m/min) | Fr (mm/r) | Ap (mm) | ||

Aluminum Alloy +(4~8% Si) | CDW010 | CDW302 | CDW005 | 100-5000 | 0.03-0.5 | 0.1~3.0 |

Aluminum Alloy (9~13% Si) | CDW010 | CDW302 | 100-3000 | 0.03-0.5 | 0.1~3.0 | |

Aluminum Alloy (>13% Si) | CDW010 | CDW302 | CDW025 | 100-2500 | 0.03~0.4 | 0.1~2.5 |

Copper alloy( Copper,Brass) | CDW010 | CDW302 | CDW025 | 100-1000 | 0.03~0.3 | 0.1~3.0 |

Titanium Alloy | CDW850 | CDW005 | 100-200 | 0.05~0.2 | 0.1~2.0 | |

Tungsten Carbide(Co>16%) | CDW302 | CDW025 | CDW010 | 15-40 | 0.1~0.25 | 0.1~1.0 |

Tungsten Carbide(Co<16%) | CDW302 | CDW025 | CDW010 | 10-30 | 0.03~0.1 | 0.05~0.3 |

Wood | CDW010 | CDW302 | CDW005 | 100-4000 | 0.1~0.4 | 0.1~3.0 |

Graphite | CDW302 | CDW025 | CDW010 | 100-600 | 0.1~0.5 | 0.05~2.0 |

Metal Matrix Composites | CDW302 | CDW025 | CDW010 | 300-600 | 0.1~0.4 | 0.2~1.5 |

Composites(Carbon Fiber) | CDW302 | CDW025 | CDW010 | 200-2000 | 0.05~0.3 | 0.1~3.0 |

Aluminum based silicon carbide composites. | CDW010 | CDW302 | ||||

Application and Cutting Conditions

Related Product Link:Auto parts solution

Related Product Link:Hard to Process Materials solution

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone