Full Name: Diamond Dresser Wheel, Diamond Dressing Rolls, Diamond Dressing Disc Wheel, Diamond Dresser roller

Process way: Grinding

Types:Forming Diamond Dressing Wheel, Diamond Dressing Disc

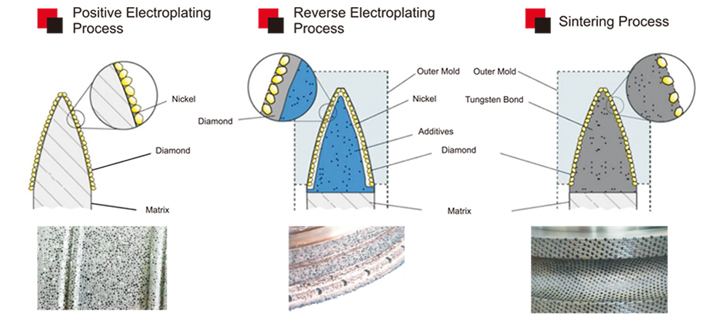

Manufacturing process: sintering method, electroplating method, CVD roller

Applications: Automobiles, machine tools, bearings, tools, aerospace, military, etc

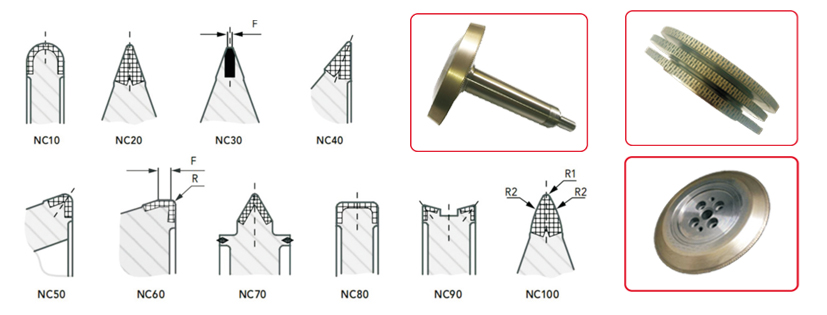

Diamond wheel can be mainly divided into two types:Forming Diamond Dressing Wheel, Diamond Dressing Disc Wheel

Diamond implantation can be mainly divided into three types: hand planting, random distribution and joint distribution.

We will optimize the dressing tools (particle size, implantation mode, diamond type) according to the grinding and dressing process parameters, grinding wheel parameters and long-term experience in Diamond wheel design, as to obtain high-quality diamond dressing wheel surface morphology.

Type | Produce Way | Code | Diamond Distribution | Diamond Density | Production Profile Complexity | Working Profile Accuracy | |

Electroplating process | External Electroplating | SG | Random distribution | Maximum density | Low | Low | |

Internal Electroplating | Random distribution internal plating | UZ | Random distribution | Maximum density | Highest | Highest | |

Regular arrangement internal plating | US | Regular arrangement | Controllable density | Commonly | Commonly | ||

Sintering Process | Random distribution Sintering | TN | Random distribution | Controllable density | Commonly | Commonly | |

Regular arrangement Sintering | TS | Regular arrangement | Controllable density | Low | Commonly | ||

Main application industries of Forming Diamond Dressing Wheel

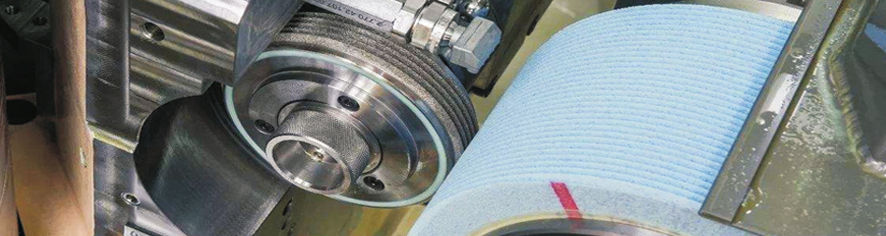

Automotive Industry - CV Joint / Crankshaft / Hub Bearing Unit / Oil Pump Nozzle / Connecting Rod, etc

Tools / Measuring Tools And Cutting Tools Industry - Caliper / Depth Gauge / Tap / Drill Bit / Hob / Broach / Saw Blade / Spindle, etc

Machine tool industry - guide rail, slider, ball screw, micro rail, etc

Aerospace, military industry, energy and other industries

Main application industries of Diamond Dressing Disc Wheel

CBN and Diamond Grinding Wheel

The diamond dressing disc adopts the point contact axial feed dressing method. Compared with the traditional single point diamond dressing tool, it greatly improves the dressing accuracy and efficiency. Through the CNC diamond dressing wheel dressing technology, it flexibly realizes the dressing of various tracks of grinding wheel products. According to the requirements of grinding wheel product specifications, it is convenient to change the Diamond Dressing Disc processing process and trim high-precision aggregate shape grinding wheels of various shapes.

Precautions for installation and use of diamond dressing wheel

1. When in use, special wheel dressing device shall be used as far as possible, and sufficient accuracy and rigidity of the machine tool and dressing device shall be ensured;

2. The linear speed ratio of the HNT Diamond Dressing Wheel dresser and the grinding wheel should be in the range of 0.4-0.7;

3. The fit clearance between the wheel and the installation mandrel shall be 0.002mm-0.005mm as far as possible to prevent vibration;

4. The user must correctly install the wheel and accurately adjust the runout of the wheel. After the wheel is installed, the radial runout and end face runout of the calibration datum plane shall reach 0.002mm;

5. It is recommended to use the hot sleeve method when installing the cargo removal wheel (that is immerse the roller in 80 ℃ water to expand its inner hole for installation; pour hot water on the outer surface of the roller during disassembly); It is strictly prohibited to directly knock the wheel to prevent damage to the profile, inner hole or end face of the wheel;

6. In the process of dressing the grinding wheel with HNT diamond dressing wheel dresser, ensure that the machine tool has reliable and sufficient cooling;

7. During the dressing process, avoid the impact of the grinding wheel on the diamond dressing wheel dresser, so as not to reduce or even damage the accuracy of the wheel; The feed rate of each trimming shall not exceed 0.02mm;

8. The HNT diamond dressing wheel dresser shall be maintained and stored carefully to prevent rust or accidental damage of the wheel.

If there are uncertain factors or uncertainties in use, please contact us immediately. It is strictly prohibited to process or change the roller without authorization, so as to avoid accidents such as loss of roller accuracy.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone