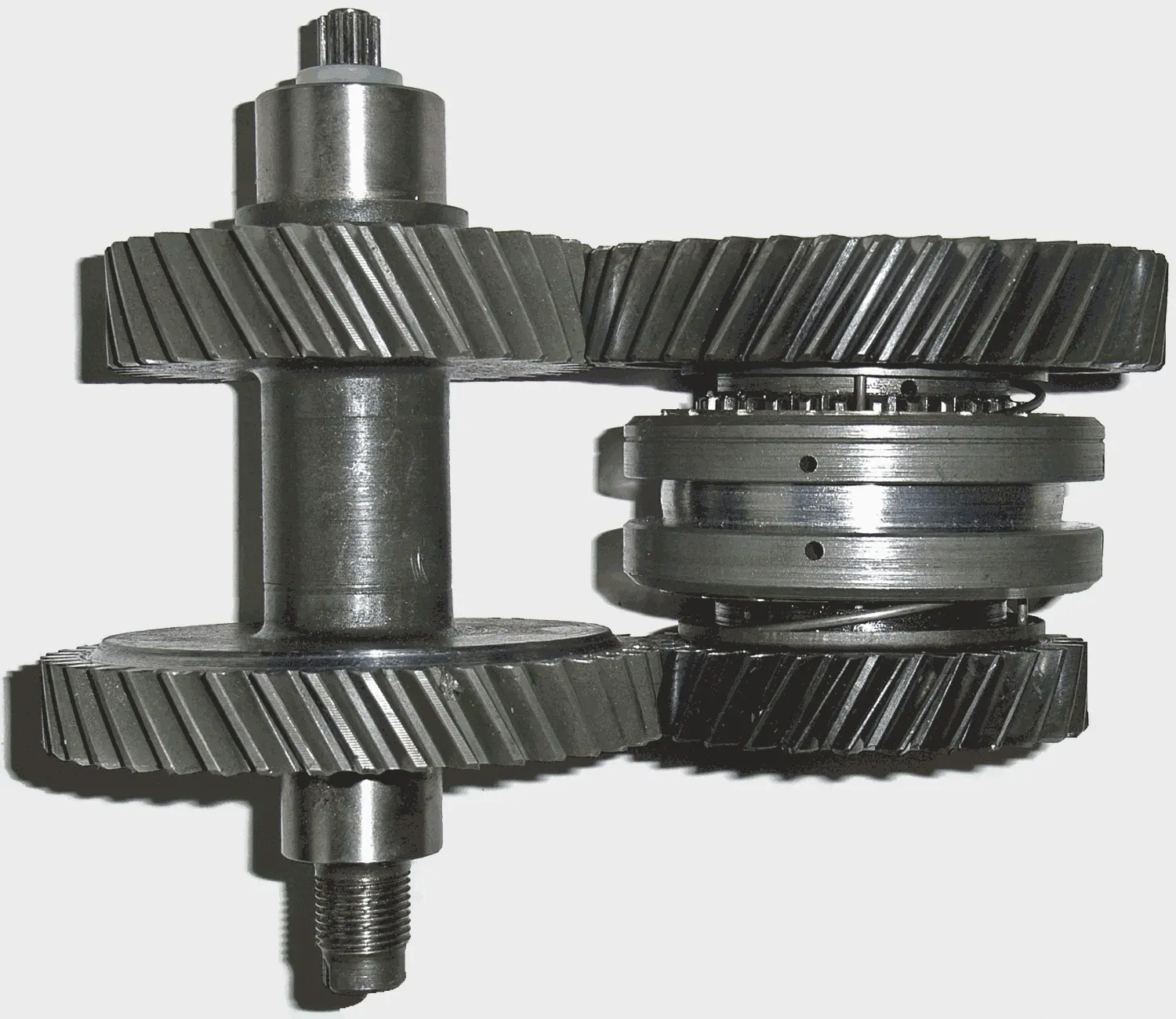

Synchronizer gear sleeve is an important equipment inside the manual gearbox structure. To ensure its excellent performance, it is often obtained by heat treatment. After heat treatment, the hardness of the synchronizer gear sleeve (combination tooth) is about HRC60, but the heat treatment deformation of the synchronizer gear sleeve on both sides and bottom needs to be reprocessed to ensure the dimensional accuracy and surface quality of the synchronizer gear sleeve.

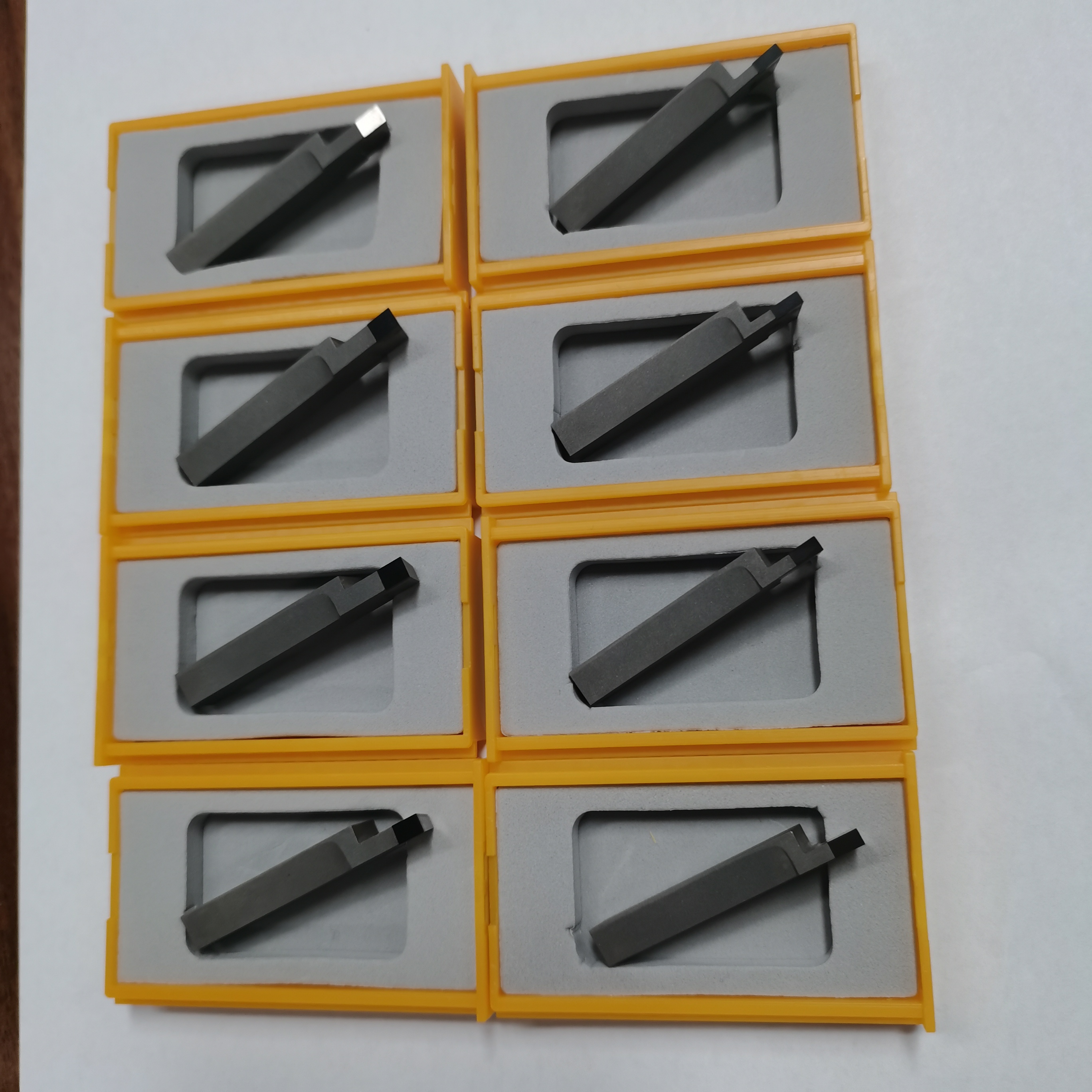

Halnn Superhard, as a pioneer in the localization of super hard tools in China, focuses on the research direction of cubic boron nitride tools and high-grade diamonds for brittle and hard materials and difficult-to-cut materials. It has unique advantages in cutting, high-speed machining, and cutting difficult-to-machine materials. In view of the characteristics of grooving after quenching of synchronizer gear sleeves (combined teeth), according to the characteristics of different machine tools used by users, two grooving tools BN-H10 and BN-H20 have been developed, with both tool durability and processing efficiency recognized by customers.

Synchronizer gear sleeve grooving processing requirements:

Synchronizer sleeve material: 20CrMnTi.

workpiece diameter is about φ160mm, groove width is 10mm.

roughness requirements: within Ra0.8, (different models have different roughness requirements, and the highest can reach Ra0.4).

hardness after quenching: about HRC60 ( HRC58-62).

Grooving solution 1:

Suitable for lathes with poor rigidity, Halnn BN-H10 grade is with good seismic performance and good toughness. CBN inserts parameters: relief angle 7 degrees, secondary deflection angle 4 degrees, tool tip arc angle R0. 4; Cutting linear speed: Vc=90-120m/min; Feed rate: Fr=0.08mm/r, the number of pieces processed at one time for tool grinding is more than 350 pieces.

Grooving solution 2:

Suitable for high-precision lathes, Halnn BN-H20 CBN inserts is with clamp structure, has longer tool life in high-speed processing, tool tip arc angle is R1.0, R0.6 and other specifications are also available. The relief angle is 3 degrees, the linear speed is 180m/min. The number of processed pieces is 450, and the efficiency is increased by 2.5 times compared with that of the grooving forming tool.

Notes:

1. Both CBN grooving tools can be designed as forming tools or machine-clamped tools according to customers requirements. The forming CBN tools can be repeatedly ground and used, which is suitable for flexible production lines; the latter is a machine-clamped tool, which has high grooving efficiency and is suitable for use of rigid beat production line.

2. The specific CBN tool angle needs to be selected according to the size of the synchronizer gear sleeve, machining allowance, and equipment condition, so as to obtain long tool life and high processing efficiency.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone