Technical requirements for brake discs,

The performance of the brake disc is a strong guarantee for the safe driving of the car, so its quality and technical requirements are relatively high.

(1) The thickness difference of the circumference of the two braking surfaces of the brake disc is usually required to be controlled within the range of 0.009mm;

(2) The parallelism of the brake disc is required to be within 0.04mm;

(3) Brake disc run-out requires an error range of 0.025mm

(4) The surface roughness of the brake disc is required to be Ra1.6.

The new process of the brake disc is carried out at the same time with two knives: the uniformity of the flatness is high, and the efficiency is doubled, especially in the assembly line operation, the efficiency is significantly improved.

Advantages of CBN tools for machining brake discs:

(1) Brake discs are mass-produced, and have stricter requirements on production and processing cycles. CBN tools have high cutting speed and can withstand high-temperature and high-speed cutting to ensure production efficiency.

(2) At the same time of high-speed cutting, it can ensure a long tool life, which is more than ten times that of traditional carbide tools.

(3) Finally, the CBN tool can easily maintain the surface roughness of Ra1.6 during the long-term machining process, and at the same time can reach the surface roughness of Ra0.8 higher.

What are the CBN tool structures for machining brake discs?

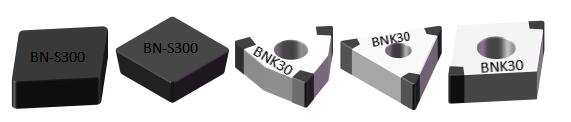

At present, two structures are commonly used for machining brake discs, one is Solid CBN InsertsBN-S300 Grade, and the other is BNK30 Grade of inlaid CBN tools.

BN-S300 Grade is mainly used for rough machining process, it can machine the surface allowance of gray cast iron with a large margin, which is more wear-resistant and more efficient than traditional carbide tools;

BNK30 Grade is mainly used for finishing process, and at the same time there are many cutting edges (6 cutting edges), which can be used on both sides more cost-effectively.

At the same time, in addition to processing brake discs, CBN tools can also process high-hardness castings (rollers, slurry pumps, mill walls, etc.), hardened steel (gears, bearings, lead screws, synchronizers), powder metallurgy and other parts. Provide turning tools (including rough turning, fine turning, slotting); milling tools (including rough milling, fine milling), boring tools (including rough boring, fine boring)

CBN tools can also be applied to: CNC lathes (CNC vertical lathes and ordinary CNC lathes), milling machines (gantry milling machines, CNC milling machines, planing and milling machines), boring machining centers/turning machining centers/milling machining centers, turning and milling compound machining centers, boring machining centers Milling compound machining center

Common models of CBN tools for machining brake discs:

(1) Solid CBN InsertsBN-S300 Grade, the rough machining process of the brake disc, the commonly used blade models are:

BN-S300 Grade CBN inserts CNMN120708, CNMN120712, CNMN120716, etc.;

BN-S300 Grade CBN inserts SCGN090408, SCGN090412, etc.

(2) Brazed CBN insertsBNK30 Grade, brake disc finishing process, commonly used insert types are:

BNK30 Grade 60° triangular CBN insert TNGA160408, etc.;

BNK30 Grade CBN insert WNGA080408, etc.;

BNK30 Grade CBN insert CNGA120408 etc.

Cutting Parameters of CBN Tool for Brake Disc Machining

CBN tools are divided into roughing and finishing. The maximum line speed for roughing can reach 1200m/min, and the line speed for finishing can reach 2000m/min. In addition, there are feed rate and cutting depth, as shown in the following table:

Halnn Grade | Material | Vc(m/min) | AP(mm) | Fr (mm/r) |

BN-S300 | Gray Cast Iron | 400-1200 | 1 to 10 mm | 0.2 to 1.0 |

BNK30 | Grey Cast Iron | 600-2000 | Less 1 mm | 0.05 to 0.3 |

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone