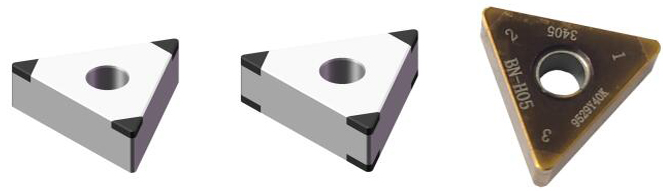

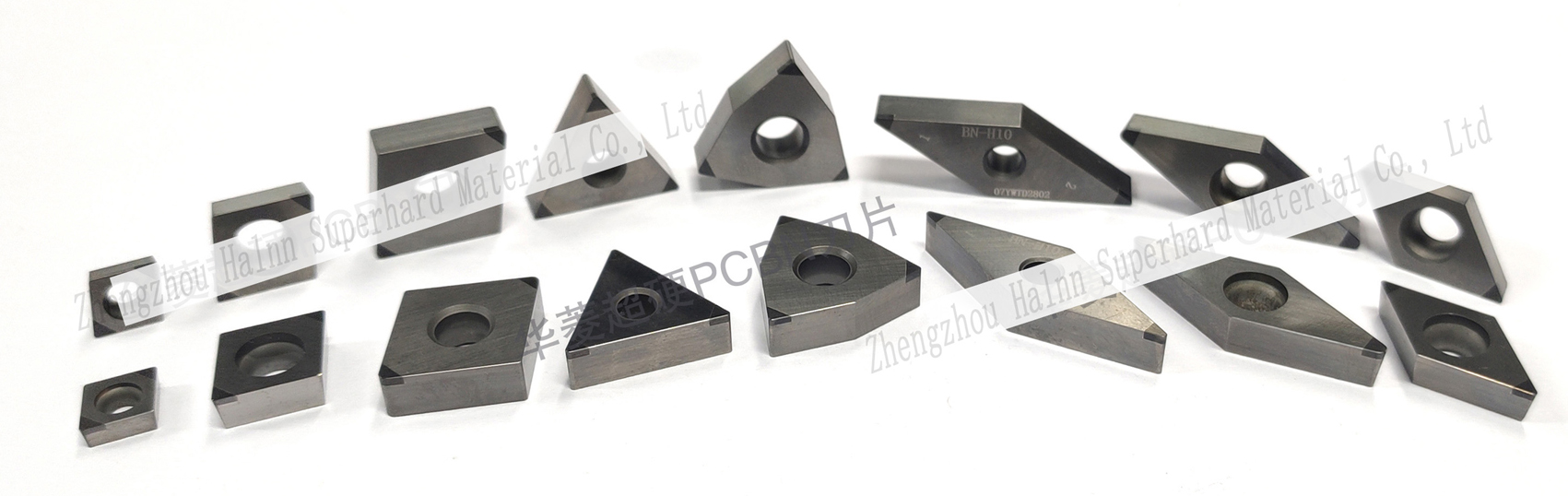

(1) PCBN inserts BN-H05: excellent wear resistance and is an ideal choice for continuous cutting.

(2) PCBN inserts BN-H10: excellent wear resistance and fracture resistance, suitable for a wider range of applications, continuous-discontinuous.

(3) PCBN inserts BN-H21: excellent fracture resistance and is very suitable for heavy intermittent machining and unstable cutting conditions.

At the same time, Halnn can also provide PCBN inserts such as coating and wiper inserts, adding coatings on the basis of composite PCBN inserts, such as coated PCBN BN-H05 C25 or C65, C75. Compared with uncoated PCBN, the inserts life is increased by at least 40%. Compared with PCBN inserts without wiper, PCBN inserts with wiper can greatly improve the surface roughness of hardened steel parts such as gear shafts and synchronizers.

The following is tool solution for hard turning gear shafts and synchronizers with PCBN inserts

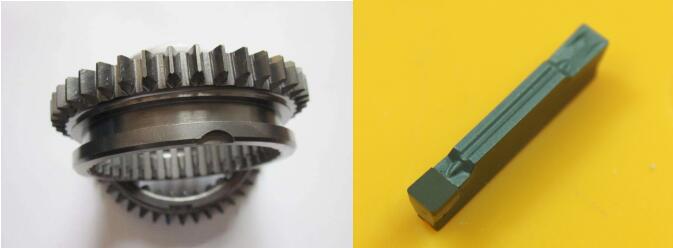

(1) Gear

Workpiece name: planetary wheel;

Material: 20CrMnTi;

Hardness: HRC58-62;

Processing parts: end face, inner hole (medium discontinuity);

Roughness requirements: end face Ra1.6, inner hole Ra0.6 (two-cut processing);

Tool Material: BN-H05 C65 CNGA120404;

Cutting parameters: Vc=166m/min, Ap=0.05mm, Fr=0.065mm/r;

Cutting method: dry cutting;

Conclusion: Compared with a certain brand of coated PCBN inserts, the tool life of BN-H10 C65 coated PCBN inserts is increased by 1.5 times.

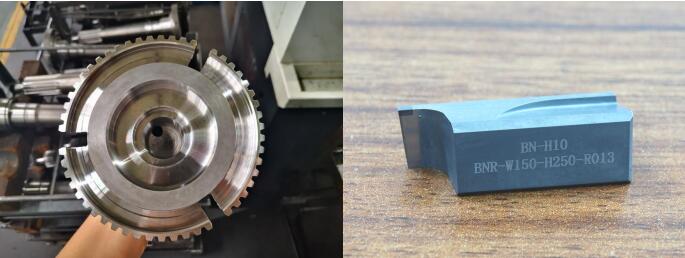

(2) Gear shaft

Workpiece material: ETN-27 (gear steel);

Workpiece hardness: HRC58-62;

Processing location: End face inner hole and end face groove (strongly interrupted);

Tool material: BN-H10 CBN grooving Tools;

Cutting parameters: Vc=70-128m /min, Ap=0.05mm, Fr=0.06mm/r;

Cutting method: wet cutting

Conclusion: Compared with imported CBN grooving inserts, the tool life of BN-H10 is 3 times longer, the efficiency is increased by 20%, and it can be used for repeated grinding.

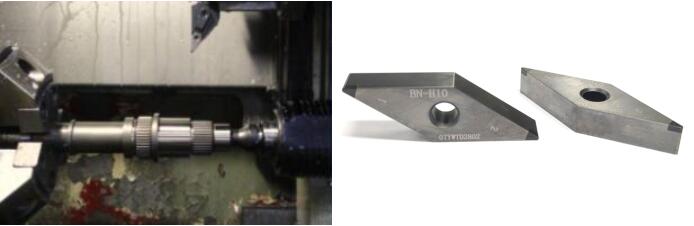

(3) Drive shaft

Workpiece material: 20CrMo;

Workpiece hardness: 62-65HRC;

Selected inserts: BN-H10 VNGA160408;

Cutting parameters: Vc=132m/min, Ap=0.1mm, Fr=0.15mm/r;

Surface quality: Ra1.6;

Cutting method: wet cutting;

Conclusion: The tool life of BN-H10 material is 45% higher than that of KBN25M material.

(4) Synchronizer

Workpiece: synchronizer gear sleeve;

Workpiece material: gear steel;

Workpiece hardness: HRC58-63;

Processing conditions: continuous cutting;

Processing location: gear sleeve groove;

Selection of inserts: BN-H20 VNGA160404;

Cutting parameters: Ap=0.15mm , Fr=0.1mm/r, Vc=170m/min;

Cutting method: dry cutting;

Conclusion: Compared with a certain brand of ceramic inserts, the life of BN-H20 material is 4 times longer, and the efficiency is increased by 40%.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone