Aluminum-based silicon carbide, abbreviated as AlSiC (SICP/Al or Al/SiC, SiC/Al), is a particle-reinforced metal matrix composite composed of silicon carbide (SiC) and granular aluminum. Materials, with excellent high hardness, high toughness, high plasticity, high modulus and other advantages, are widely used in aviation, aerospace, electronic chips, high-speed rail, satellites and other fields.

Common processing methods of aluminum-based silicon carbide composites include milling, drilling, etc., to process curved surfaces, holes, and grooves. In order to better control the cost, rough machining can be performed with carbide tools, and PCD tools can be used for milling and drilling for finishing. As a new type of modern composite material, aluminum-based silicon carbide composite material has many advantages, but it also has obvious disadvantages, that is, it is difficult to machine, the tool wears quickly, the production cost is high, and the efficiency is low. For aluminum-based silicon carbide composite materials, Halnn's commonly used tools include PCD milling cutters and PCD drill bits. Common grades are CDW010, CDW025, and CDW302, according to the composition of aluminum-based silicon carbide, different materials are selected for efficient processing.

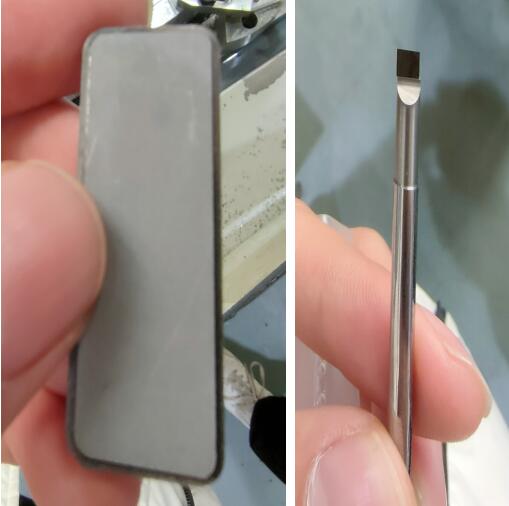

The following are the case parameters of Halnn PCD milling cutter milling aluminum-based silicon carbide

Processing method: milling processing

Tool used: φ4 PCD end mill

Use machine tool: Beijing Seiki

Processing part: step cleaning

Application industry: satellite parts

Result: The tool life of a single cutting edge of the Halnn PCD milling cutter is 4 hours, which is 12 times of a cemented carbide cutter and 1.5 times of a domestic brand PCD cutter.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone