Reasons of chamfering of bearing rings:

1. The bearing ring must be chamfer during rough machining before heat treatment, so that during the heat treatment of the material, the release of stress, the redistribution of the internal structure, the resistance to cracks, and the reduction of deformation are very important. Chamfering can solve the problem of stress concentration.

1. Chamfering and deburring make the product unsharp and will not cut the user.

2. It plays a role of guiding and positioning during assembly.

There are PCBN and ceramic inserts for bearing ring chamfering blades. In fact, many companies still mainly use ceramic inserts, such as plum blossom-shaped, triangular and other shapes.

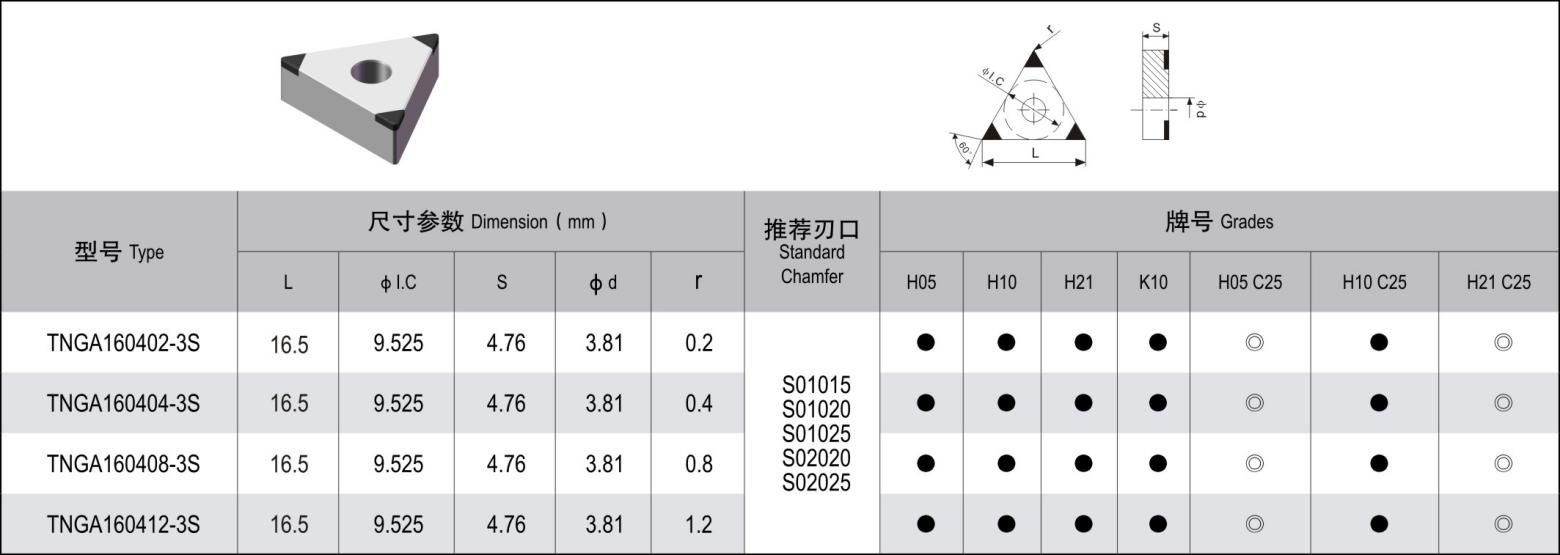

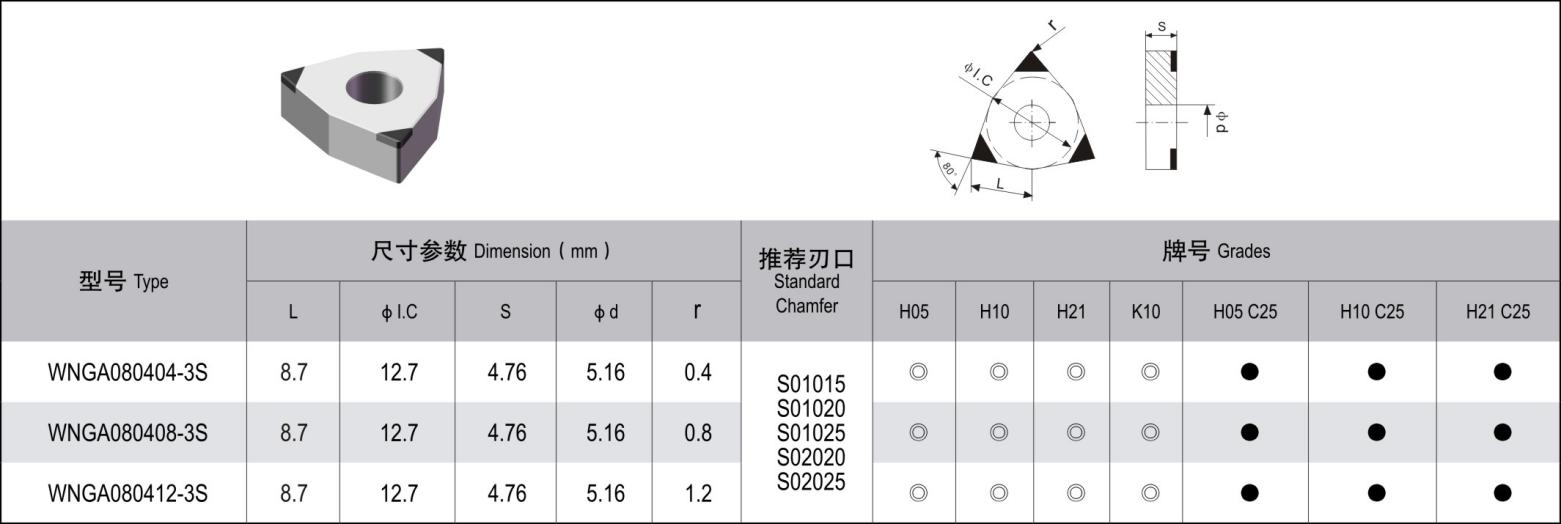

Halnn Superhard, a pioneer in China’s professional hard material processing tools, and a high-tech enterprise of superhard tools and abrasives. Focus on the research direction of cutting tools for brittle, hard materials and difficult-to-cut materials, and is committed to providing customers with complete set of cutting tool solutions, not only providing PCBN tools, diamond tools, but also providing customers with some heterogeneous inserts or customized tools. Meanwhile, for the chamfered part of the bearing ring, some standard models are also available, such as the T-shaped and the W-shaped in the PCBN cutter can process the chamfered part of the bearing ring.

PCBN and ceramic inserts which is more suitable for machining the chamfered part of the bearing ring needs to be measured according to the actual processing conditions, production cycle, production cost and other conditions.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone