The finishing process of the bearing includes the processing of the outer circle, the end face and the inner hole, as well as the processing of the chamfering part.

Finished bearings generally belong to the final machining process, so they have generally undergone a heat treatment process and have high hardness. At this time, the selection of finishing tools should be cautious, otherwise it is easy to cause waste. The bearing hardness after heat treatment is about HRC60, which requires the tool to have the advantages of high hardness, high wear resistance, and high resistance to willfulness. As far as the current tool material is concerned, PCBN inserts is the most suitable tool material.

PCBN inserts is currently the highest hardness tool material for processing ferrous metals, followed by ceramic tools, and finally carbide tools, so it is more suitable to choose PCBN insertss for high-hardness bearings after heat treatment.

The following introduces the PCBN inserts material and common models of the finishing bearings (including bearing chamfering tools) provided by Halnn Superhard.

Halnn Grade | Halnn Grade | CBN Content | Granularity | Hardness(HV) |

BN-S20 | TIN | 76 | 4 - 6 | 2900-3100 |

BN-S200 | TIN | 60 | 2 - 4 | 2800-3000 |

BN-H11 | TIN | 70 | 2 - 4 | 2800-3000 |

BN-H20 | TIC | 80 | 2 - 4 | 3100-3300 |

BN-H05 | TIN | 45 | ≤1 | 2700-2800 |

BN-H10 | TIN | 50 | ≤1 | 2700-2800 |

BN-H21 | AL,TINC | 60 | 1 - 2 | 2600-2800 |

BN-H05 C25 | TIN | 45 | ≤1 | 2700-2800 |

BN-H10 C25 | TIN | 50 | ≤1 | 2700-2800 |

BN-H21 C25 | AL,TINC | 60 | 1 - 2 | 2600-2800 |

(1) Type of insert for finishing the bearing end face

There are TNGA series, WNGA series and CNGA series of insert models for finishing the bearing end face.

The specific models are TNGA160404/08/12/16, WNGA080404/08/12, CNGA120404/8/12/16

As shown below:

(2) For finishing the outer circle of the bearing

There are many types of inserts for finishing the outer circle of the bearing, and they can basically be used for the machining of the outer circle, such as TC series, W type, CN series, CC series, V type, D type.

(3) For finishing the inner hole of the bearing

There are TN series, TC series, CN series, CC series, WN series of inserts for finishing the inner hole of the bearing.

The specific models are: TNGA160404/08/12/16, TCGW0902/1102/16T3, CNGA120404/8/12/16, CCGW0602/09T3/1204, WNGA080404/08/12.

The details are as follows:

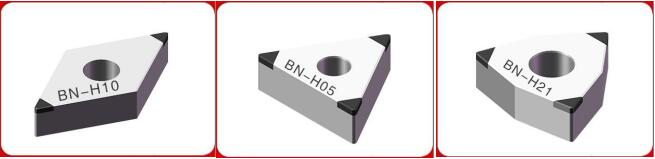

(4) Insert type for finishing bearing chamfering

Before introducing the bearing inserts, let's first introduce why the bearing needs chamfering. Chamfering is a term in mechanical engineering. In order to remove the burrs caused by machining on the parts, and also to facilitate the assembly of the parts, chamfers are generally made at the ends of the parts.

1. Bearing steel must be chamfered during rough machining before heat treatment, so that when the material is heat treated, the stress is released, the internal structure is redistributed, cracks are not easy to appear, and deformation is reduced. It has a very important role. Chamfering can solve the problem of stress concentration.

2. Chamfer and deburr, so that the product is not sharp and will not cut the user.

3. It plays the role of guiding and positioning during assembly.

The following introduces the selection of inserts for finishing bearing chamfers:

The Model of the finishing bearing chamfering part can be selected from PCBN insertsor ceramic inserts, depending on which one is more economical and cost-effective.

Among them, PCBN inserts can be TN series, CN series inserts (such as the above inserts pattern), ceramic inserts can also be used, but many chamfered inserts are also non-standard customized, such as inserts similar to plum blossoms, triangular inserts and other shapes.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone