GCr15 is the bearing steel with the largest production volume in the world. Generally, manufacturers use heat treatment to improve the performance of the workpiece. After heat treatment, the hardness of GCr15 bearing steel reaches HRC60-62, which makes it form a hard surface on the surface of the core with good toughness. How to turn GCr15 bearings? What is the effect of PCBN Inserts turning GCr15 bearing steel?

Processing technology of GCr15 bearing

Processing route: spheroidizing annealing - roughing - vacuum quenching - low temperature tempering - finishing - stabilization treatment - storage.

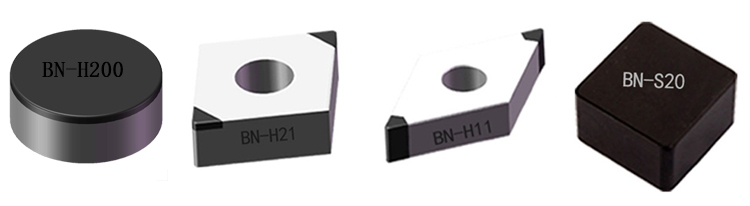

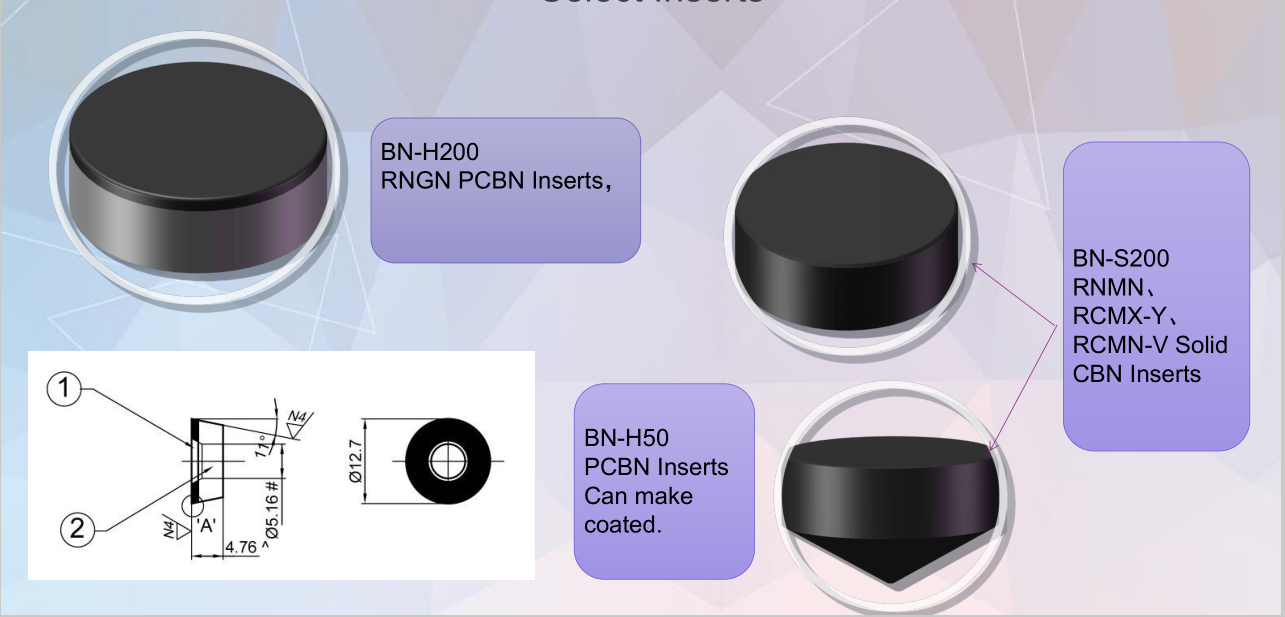

This is a new machining process for turning GCr15 bearings using CBN Inserts BN-H200 grade (new material). Early fine grinding is a common process for finishing GCr15 bearings. With the improvement of the precision of CNC machine tools and other processing equipment, and the application of CBN Inserts BN-H200 material and BN-H11CBN Inserts, turning instead of grinding can complete the final finishing of GCr15 bearings.

BN-H200 grade and BN-H11 new grade CBN Inserts have become a new way to turn GCr15 bearing steel with turning instead of grinding.

GCr15 bearings have two processing conditions, continuous and intermittent. For example, wind power bearings are large parts and have a large amount of deformation after heat treatment. The margin here is 0.5mm, and the margin there may reach 1mm. This situation also belongs to intermittent processing. Under the working conditions, the welded CBN insert is not suitable at this time, and it is easy to break. At this time, the GCr15 bearing is turned with BN-H200 material, which not only does not break, but also the finished insert can be used for rough machining. BN-H200 material belongs to Full Face CBN Inserts, and the feed is about 2mm at a time.

For continuous turning GCr15 bearings, if the allowance is less than 0.5mm, the hard turning effect of BN-H11 material is better, the surface finish is within Ra0.4, the service life is long and durable, and it is a relatively economical material. Coated CBN Inserts BN-H10 C25 grades are also available, extending tool life by at least 35%.

At the same time, for GCr15 bearings with a margin greater than 2mm, the BN-S20 grade solid CBN Inserts is more suitable and has higher durability. This material belongs to the overall polycrystalline CBN Inserts, with a machining allowance of more than 2mm, and can withstand strong intermittent machining. condition.

Summarize

The hardness of GCr15 bearing after heat treatment is between HRC60-62, and it is turned with CBN inserts BN-H200 material and BN-H11 material, and the finish reaches Ra0.4.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone