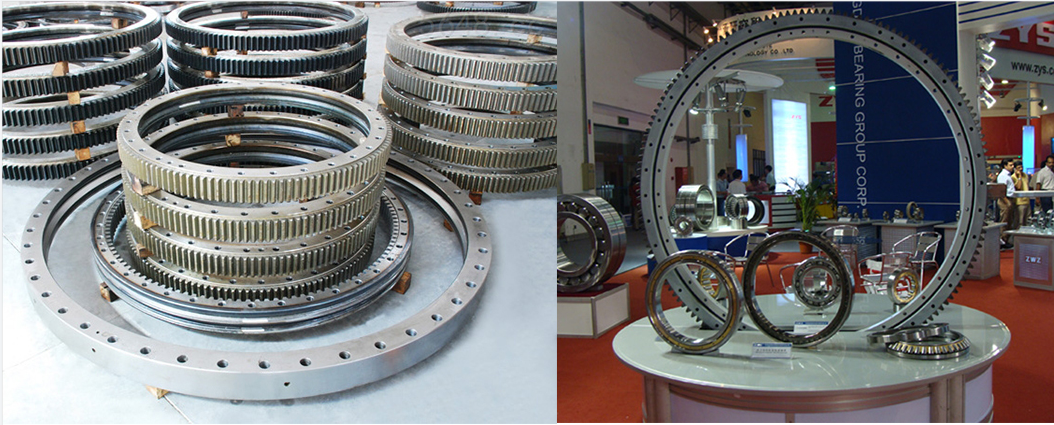

Outer raceways, inner raceways, and rib positions are the main hard turning parts of wind turbine bearings and slewing ring bearings. The general materials are BN-H200 and the common inserts are mainly round ones, such as RNGN090300, RCGX120700, and RNGN120700. Halnn can provide RCMX series, RCGW series, RNGN series, RCGO series, single-sided composite PCBN, round single-sided composite perforated PCBN inserts, solid CBN inserts and also accept customization. These inserts have large cutting margin and can bear interrupted cutting, can effectively meet the needs of customers to reduce costs and increase efficiency.

BN-H200 is a kind of PCBN tools newly developed by Halnn, which is mainly used in the fields of large slewing bearings and wind power bearings. The current market share has reached more than 60%. BN-H200 can cut with a large margin during rough machining, does not collapse under intermittent working conditions. It can obtain roughness and dimensional accuracy within Ra1.6 during finishing, and can be used for dry cutting, wet cutting, air-cooled, etc. The cutting performance is extremely stable, and it can replace imported and homogeneous PCBN inserts.

The parameters of BN-H200 for hard turning slewing bearing and wind power bearing are as follows

Material: 50Mn

Hardness: HRC55-62

Processing parts: inner raceway, outer raceway (diameter 1530mm)

Roughness: Ra1.6

Inserts model: BN-H200 RCGX120700

Cutting parameters: Vc=180m/min, Fr=0.5mm/r, Ap=0.2mm

CBN inserts parameters of a certain brand: Vc=140m/min, Fr=0.5mm/r, Ap=0.2mm

Processing method: dry cutting

Tool life: 40 pieces

A domestic brand of coated CBN inserts: 35 pieces

Conclusion: Not only the tool life is longer than a certain brand of CBN blade, but the efficiency is increased by 28%, which meets the needs of customers to increase efficiency.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone