Turning hardened steel with CBN tools not only simplifies the machining process, lowers costs, and reduces cycle times, it also avoids environmental costs associated with coolant and grinding waste, making it an alternative to grinding hardened parts.

Halnn recommends suitable CBN tool types for different processing parts of hardened steel as follows

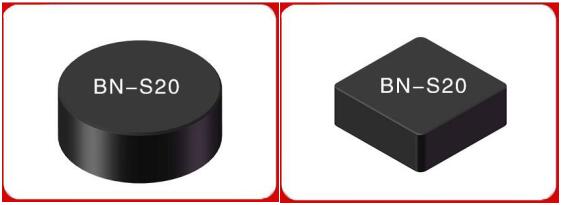

Solid CBN inserts

Most hardened steel workpieces have small margins, and are commonly processed with brazed CBN tools (BN-H05, BN-H10), but some parts such as wind turbine bearings, slewing ring bearings, and ball screw shafts have a machining margin of more than 1mm. When using solid CBN tools BN-S20 and BN-H200, the hard turning effect is good.

Common Solid CBN inserts types: BN-H200 RNGN090300; BN-S20 SNGN090404, CNGN120708, RCMX120700

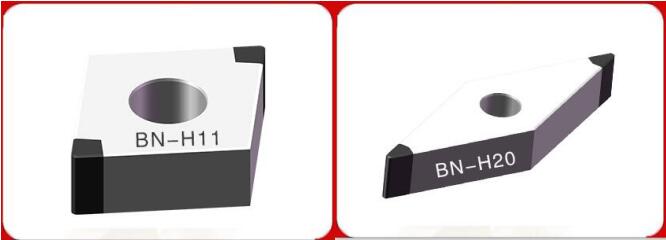

Brazed CBN inserts

Brazed CBN inserts are more cutting edge more economical, and are mostly used when the requirements for finish and precision are not high. For example, if the finish is required to be Ra0.8, Brazed CBN inserts BN-H11 and BN-H20 can be selected for machining hardened steel

Common Brazed CBN inserts types: BN-H11 DNGA160404,CNGA120408; BN-H20 VNGA160404

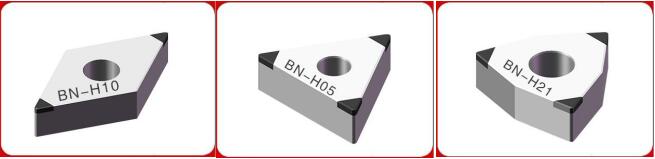

PCBN inserts

PCBN inserts is mainly used in the case of high finish and high precision. For example, the finish requires Ra0.4 and the accuracy is required to be within 2μm. PCBN inserts BN-H05, BN-H10, BN-H21 is used for cutting and machining hardened steel with high efficiency

Common PCBN inserts types: BN-H05 CNGA120408, TNGA160404; BN-H10 CCGW09T304, VNGA160408; BN-H21 WNGA080404, CNGA120408

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone