Powder metallurgy material is a kind of special material. Its difficult processing problems are mainly the wear resistance of the tool and the poor processing effect, so it is very important to choose the right tool.

Characteristics of iron-based powder metallurgy parts

Porous structure: Porosity leads to easy fatigue of the cutting edge of the tool, resulting in accelerated wear and even chipping

low thermal conductivity: The cutting temperature is very high, which can easily lead to tool wear and even deformation, requiring frequent tool changes, or causing parts to be scrapped.

High hardness: The material hardness too high, which is easy to cause accelerated tool wear

Halnn CBN tools turning Iron-based powder metallurgy turning advantages

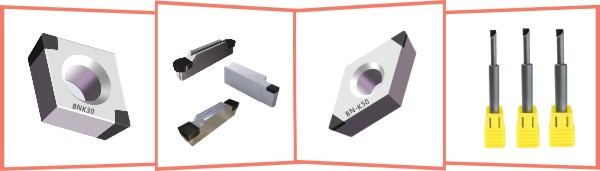

Halnn CBN tools have higher wear resistance and lower surface roughness (surface finish) when turning powder metallurgy materials. For powder metallurgy, Halnn BN-K50, BNK30, BN-K10, BN-H21 (intermittent) grade CBN cutting tools are prefect.

Halnn CBN tools turning iron-based powder metallurgy cutting parameters

Machining material | Recommended cutting parameters | CBN insert Grade | ||

Cutting speed VC(m/min) | Cutting Depth ap (mm) | Feed Rate Fr(mm/r) | ||

Powder metallurgy | 80-150(Roughing) | ≥0.5mm | 0.1-0.5 | BNK30, BN-K10, BN-K50, BN-H21 |

90-350(Finishing) | ≤0.5mm | 0.1-0.2 | ||

Application case

| Workpiece: Synchronized pulley(Finishing) | ||

Material: Powder metallurgy | |||

Insert Type: BN-K50 DCGW11T304 | |||

Cutting parameters: Vc=150m/min, Fr=0.1mm/r, ap=0.2mm | |||

Processing method: Dry cutting | |||

Insert grade | Roughness | Tool Life/edge | |

Halnn BN-K50 | ≤Ra0.8 | 450 pcs | |

Other CBN inserts | Ra1.0 | 300 pcs | |

Workpiece: Valve seat ring |  | |||

Material: Powder metallurgy | ||||

Insert Type: BN-K10 CCGW060204 | ||||

Cutting parameters: Vc=160m/min, Fr=0.03mm/r, ap=0.05mm | ||||

Processing method: dry cutting | ||||

Insert grade | Cutting Speed | Tool Life/edge | Roughness | |

Halnn BN-K10 | 160m/min | 400pcs | ≤Ra0.8 | |

Other CBN inserts | 130m/min | 280pcs | Ra1.0 | |

| Workpiece: Powder high speed steel mold (HRC65) | ||

Processing conditions: Heavy interrupted cutting | |||

Insert Type: BN-H21 CNGA120408 | |||

Cutting parameters: Vc=35-60m/min, Fr=0.1mm/r, ap=0.15mm | |||

Processing method: Dry cutting | |||

Insert grade | Tool Life/edge | Failure Mode | |

Halnn BN-H21 | 5pcs | Normal Wear | |

Other CBN inserts | <1pcs | Broken | |

Workpiece: Gearbox hub (face machining) |  | ||

Material: Powder metallurgy | |||

Insert Type: BNK30 CNGA120408 | |||

Cutting parameters: Vc=200m/min, Fr=0.1mm/r, ap=0.25mm | |||

Processing method: Dry cutting | |||

Insert grade | Tool Life | Efficiency | |

Halnn BNK30 | 700pcs | Improved 2.5 times | |

Coated carbide inserts | 60pcs | ------ | |

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone