In recent years, the world's industrially developed countries and major domestic companies have rushed to develop new polycrystalline diamond tool materials to solve the machining problems of metal matrix composite materials. Among them, the most representative ones are the series of polycrystalline diamond (PCD) tools materials developed by Zhengzhou Halnn Superhard Materials Co., Ltd., such as CDW010, CDW025 and CDW302. Generally, the coarser the particles, the better the wear resistance of the tool.

CDW010, CDW025 and CDW302 are synthetic polycrystalline diamond (PCD) tools. The so-called polycrystalline PCD tools are made of natural or synthetic diamond powder and binder (containing cobalt, nickel and other metals) in a certain proportion. It is sintered under high temperature (1000~2000℃) and high pressure (50,00~100,000 atmospheres).

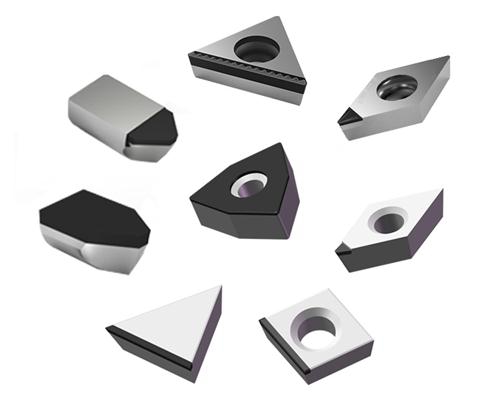

The advantages of Halnn diamond (PCD) inserts for cutting metal matrix composites.

Long tool life

Halnn PCD tools process metal matrix composite materials. The average tool durability is 50-100 times that of other tool materials. Moreover, when the wear of other tool materials increases sharply, the wear out rate of Halnn PCD tools and diamond-coated tools remains stable.

Good surface finish

The built-up edge and the reinforcement phase are the two main factors that affect the surface roughness of the metal matrix composite material. The built-up edge will promote the formation of scales during the cutting process, which will reduce the surface processing quality, and Halnn PCD tool Compared with other tools, there are very few built-up edge, the processed surface roughness Ra is the smallest, and the finish is the best.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone