Slurry pump the high chromium cast iron material has relatively high hardness. Halnn BN-K1 grade is prefect. it can turn the slurry pump body with a large margin, and intermittently turn the slurry pump impeller, etc. It better solves the problem of tool breakage and rapid wear when the tool is turning slurry pump.

Advantages of Halnn BN-K1 grade CBN inserts

High hardness: its hardness is as high as 8000-9000HV, second only to diamond.

Good thermal stability: The thermal stability of BN-K1 grade is much higher than that of diamond. Synthetic diamond begins to carbonize at 800 ℃ in the air, while BN-K1 grade can still be cut at 1300 ℃, and there is no phase change even at 1500 ℃.

High chemical inertness: Like ceramic tools, BN-K1 grade has the characteristics of high chemical inertness. When the temperature is as high as 1200-1300 ℃, it is not easy to chemically react with ferroalloy materials.

Halnn BN-K1 grade CBN insert for Interrupted machining HRC60-68 high hardness cast iron machine parameters

Rough turning: ap=1-10mm, Vc=90-150m/min, Fr=0.15-0.25mm/r

Application case

| Workpiece: Slurry pump body | ||

Material: Cr26(Hardness HRC60) | |||

Insert Type: BN-K1 CNMN120712 | |||

Cutting parameters: Vc=75m/min, Fr=0.12mm/r, ap=2.5mm | |||

Processing method: dry cutting | |||

Insert grade | Tool Life/edge | Failure mode | |

Halnn BN-K1 CBN inserts | 85pcs | Normal wear | |

Some brand CBN | 35pcs | Damage rupture | |

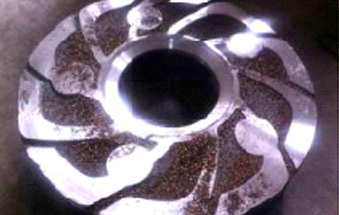

Workpiece: Slurry Pump impeller |  | ||

Materials: High chromium cast iron Cr26(Hardness HRC60) | |||

Insert Type:BN-K1 SNMN120712 | |||

Cutting parameters:Vc=45m/min, Fr=0.25mm/r, ap=2.5mm | |||

Processing method: Heavy Interrupt dry Turning | |||

Insert grade | Tool Life/edge | Failure mode | |

Halnn BN-K1 | 11pcs | Normal wear | |

Some brand CBN | 3pcs | Damage rupture | |

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone