The bearing material is generally bearing steel, which is divided into high carbon chromium bearing steel, carburized bearing steel, stainless bearing steel, slewing bearing steel and special performance steel.

Common bearing steels are GCr15, 42CrMo, 50Mn, which are commonly used materials for large wind power bearings, slewing ring bearings, and metallurgical bearings.

The different types of bearing steel grades are as follows

Name | Type |

High Carbon Chromium Bearing Steel | GCr15 GCr15SiMn GCr15SiMo GCr18Mo |

Carburizing Bearing Steel | G20CrMo(A) G20CrNiMo(A)(C-8620) G20CrNi2Mo(A)(C-4320) G20Cr2Ni4(A) G10CrNi3Mo(A)(E-9310) G20Cr2Mn2Mo(A) |

Stainless bearing steel | 9Cr18 9Cr18Mo 1Cr13~4Cr13 |

Steel for Slewing Ring Bearings | 42CrMo 5CrMnMo 50Mn |

Special performance steel | Cr4Mo4V QBe2 |

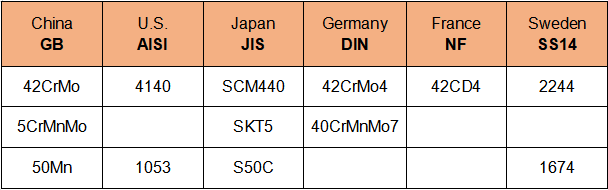

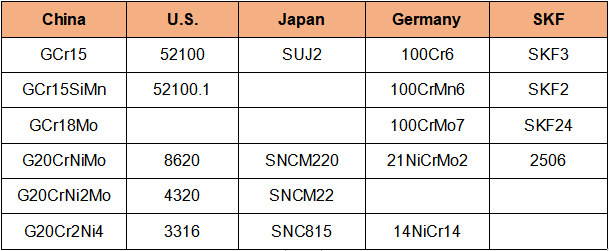

Internationally common bearing material grades

Turning bearing insert type is selected according to the bearing type and processing technology. Halnn CBN BN-S20, BN-H11, BN-H200, BN-H20 grades are widely used in bearing turning. The recommended cutting parameters are as follows

Machining workpiece | Recommended cutting parameters | CBN insert Grade | ||

Cutting speed VC(m/min) | Cutting Depth ap (mm) | Feed Rate Fr(mm/r) | ||

Bearing | 50-150(Roughing) | 1-10 | 0.1-0.5 | BN-S20 |

90-250(Finishing) | ≤1 | 0.05-0.35 | BN-S200, BN-H200, BN-H11, BN-H10, BN-H10 C25 | |

Application case

| Workpiece: Metallurgical Bearings( GCr15) | |||

Machining parts: outer circle, inner hole | ||||

Hardness: HRC62 | ||||

Insert Type: BN-H11 DNGA150408 | ||||

Cutting parameters: Vc=140m/min, Fr=0.12mm/r, ap=0.5mm | ||||

Processing method: dry cutting | ||||

Insert grade | Cutting Speed | Tool Life/edge | Roughness | |

Halnn BN-H11 | 140m/min | 12pcs | Ra0.8 | |

Other Brand CBN | 140m/min | 10pcs | Ra0.8 | |

Workpiece: Wheel hub bearing unit Hardness: HRC58-62 Inserts type: BN-H10 C25 CNGA120408 Processing parameters: Vc=180m/min, Fr=0.1mm/r, ap=0.15mm Roughness: ≤Ra0.6

Coated inserts can achieve better cutting performance, improve machining accuracy and life |  |

| Processing part: Outer ring raceway of wind power bearing |

Recommended Cutting parameters:

Small and medium-sized bearings and non-standard bearing inner and outer rings for fine turning (hardness of Gcr15 material is above HRC62)

Recommended grade: BN-H20 (margin <0.5mm); BN-S20 (margin >1mm)

Recommended Cutting parameters: ap=0.1-0.3mm, Fr=0.1-0.12mm/r, Vc=120-180m/min

Turning slewing ring bearing raceway, end face, hardness HRC47-55, margin <2mm

Recommended grade: BN-S200 grade(round insert)

Recommended cutting parameters: ap≤1mm, Fr=0.05-0.35mm/r, Vc =60-250m/min

Processing effect: The tool life is 7 times that of ceramic tools, and the surface roughness is controlled between Ra0.6-1.0

Turning the outer circle and end face of the slewing ring bearing, the hardness is HRC47-55, the channel hardness is HRC55-62, margin ≥ 2mm

Recommended grade: BN-S20 grade

Recommended cutting parameters: ap=1mm, Vc=140 -180m/min

Processing effect: long tool life, can replace rough grinding, surface roughness reaches Ra0.4

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone