Hardened steel typical parts include gears, driveshafts, bearings, ball screws, ball cages, synchronizer gear sleeves, HSS rolls, etc. The hardness is above HRC50, and Halnn CBN tools are used to turn hardened steel, the processing process is simpler, and the cost is Lower, with higher production efficiency, at the same time, no cutting fluid is added when turning quenched steel, which is greener and environmentally friendly

Application case

| Workpiece: Driveshafts |

Workpiece material: 20CrMo | |

Workpiece hardness: 62-65HRC | |

Inserts type: BN-H10 VNGA160408 | |

Cutting parameters: Vc=132m/min, ap=0.1mm, fr=0.15mm/r | |

Surface roughness: Ra1.6 | |

Processing method: wet cutting | |

Result: BN-H10 grade tool life is 45% higher than that of KBN25M grade inserts |

| Workpiece: Gears |

Machining conditions: continuous cutting | |

Workpiece material: 20CrMnTi | |

Workpiece hardness: 58-62 HRC | |

Inserts type: BN-H05 CNGA120408 | |

Cutting parameters: ap=0.1mm, Fr=0.1mm/r, Vc=180m/min | |

Processing method: dry cutting | |

Result: BN-H05 grade tool life is 45% higher than that of other brand CBN inserts |

| Workpiece: Gear |

Machining conditions: Light interrupted cutting | |

Processing material: 20CrMnTi | |

Workpiece hardness: 58-62HRC | |

Inserts type: BN-H10 CCGW09T304 | |

Cutting parameters: ap=0.25mm, Fr=0.08mm/r, Vc=135m/min | |

Processing method: dry cutting | |

Result: BN-H10 grade tool life is 66% higher than that of imported CBN inserts, and increases 22% in efficiency |

| Workpiece: Gear |

Machining conditions: Heavy interrupted cutting end face | |

Processing material: 20CrMnTi | |

Workpiece hardness: 58-62HRC | |

Inserts type: BN-H21 WNGA080404 | |

Cutting parameters: ap=0.15mm, Fr=0.1mm/r, Vc=117m/min | |

Processing method: dry cutting | |

Result: Compared with other Brand CBN inserts, the BN-H21 grade tool life improves 5 times, and excellent impact resistance and wear resistance in heavy interrupted processing |

| Workpiece: Wheel hub bearing unit |

Machining conditions: continuous chips | |

Workpiece hardness: 58-62HRC | |

Inserts type: BN-H10 C25 | |

Cutting parameters: Vc=180m/min, Fr=0.1mm/r, ap=0.15mm | |

Roughness: ≤Ra0.6 | |

Result: Coated CBN inserts have more excellent cutting performance, higher precision, and longer tool life |

| Workpiece: Ball screw |

Processing method: continuous cutting | |

Workpiece material: Gcr15 | |

Workpiece hardness: 60-62HRC | |

Inserts type: BN-S20 CNGN120708 | |

Cutting parameters: ap=4.5mm, Fr=0.10mm/r, Vc=95m/min | |

Processing method: dry cutting | |

Result: The cutting depth of BN-S20 grade inserts is 8 times that of ceramic inserts, and wears normally |

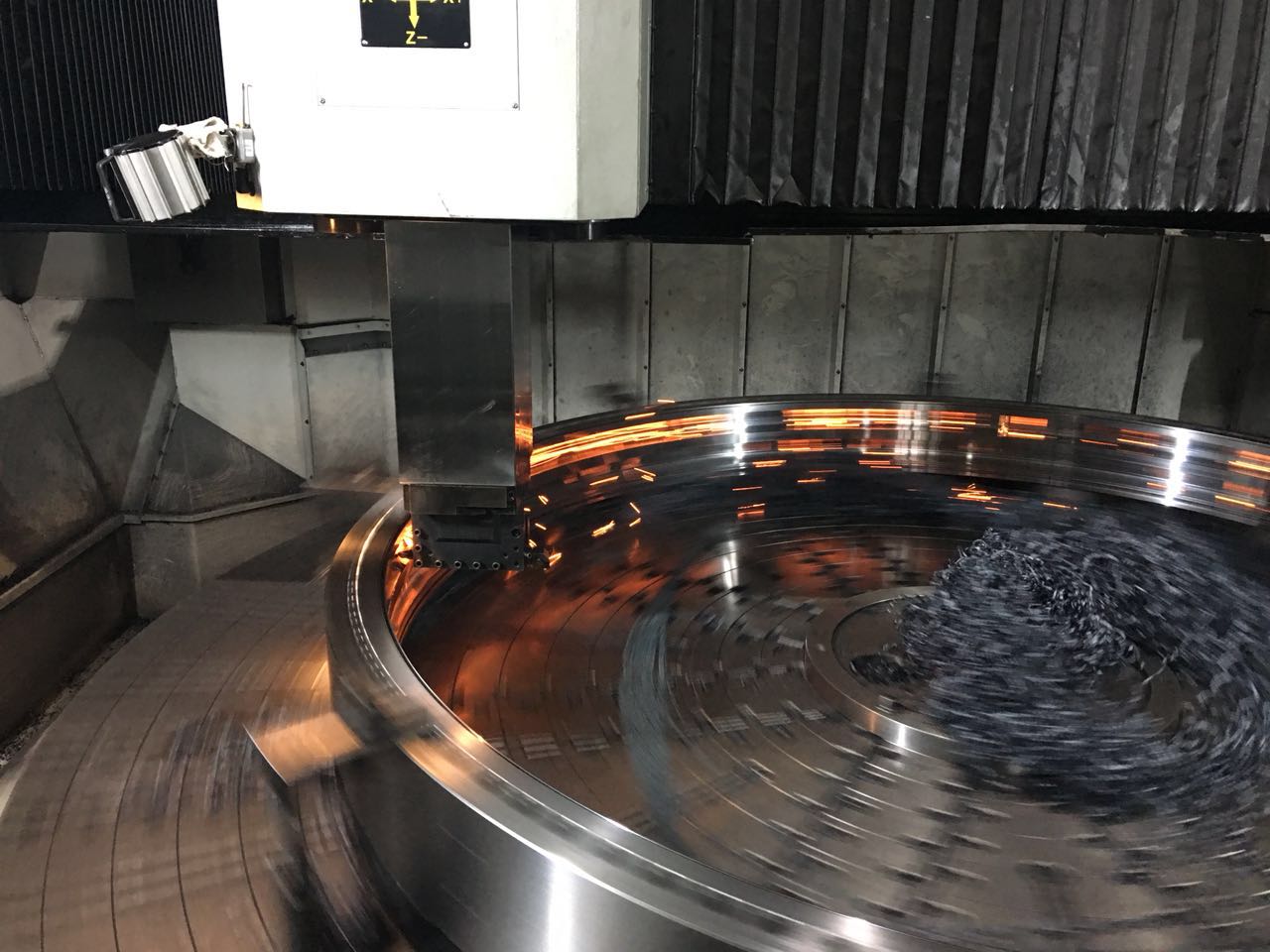

| Workpiece: Wind power bearing |

Workpiece material: 42CrMo4 | |

Workpiece hardness: HRC58-62 | |

Machining conditions: light interrupted cutting | |

Inserts type: BN-H200 RNGN090300 | |

Cutting parameters: ap=1mm, Fr=0.45mm/r, Vc=145m/min | |

Processing method: dry cutting | |

Result: Compared with other brand CBN inserts, the BN-H200 grade increases 20% in efficiency and 50% in tool life |

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone