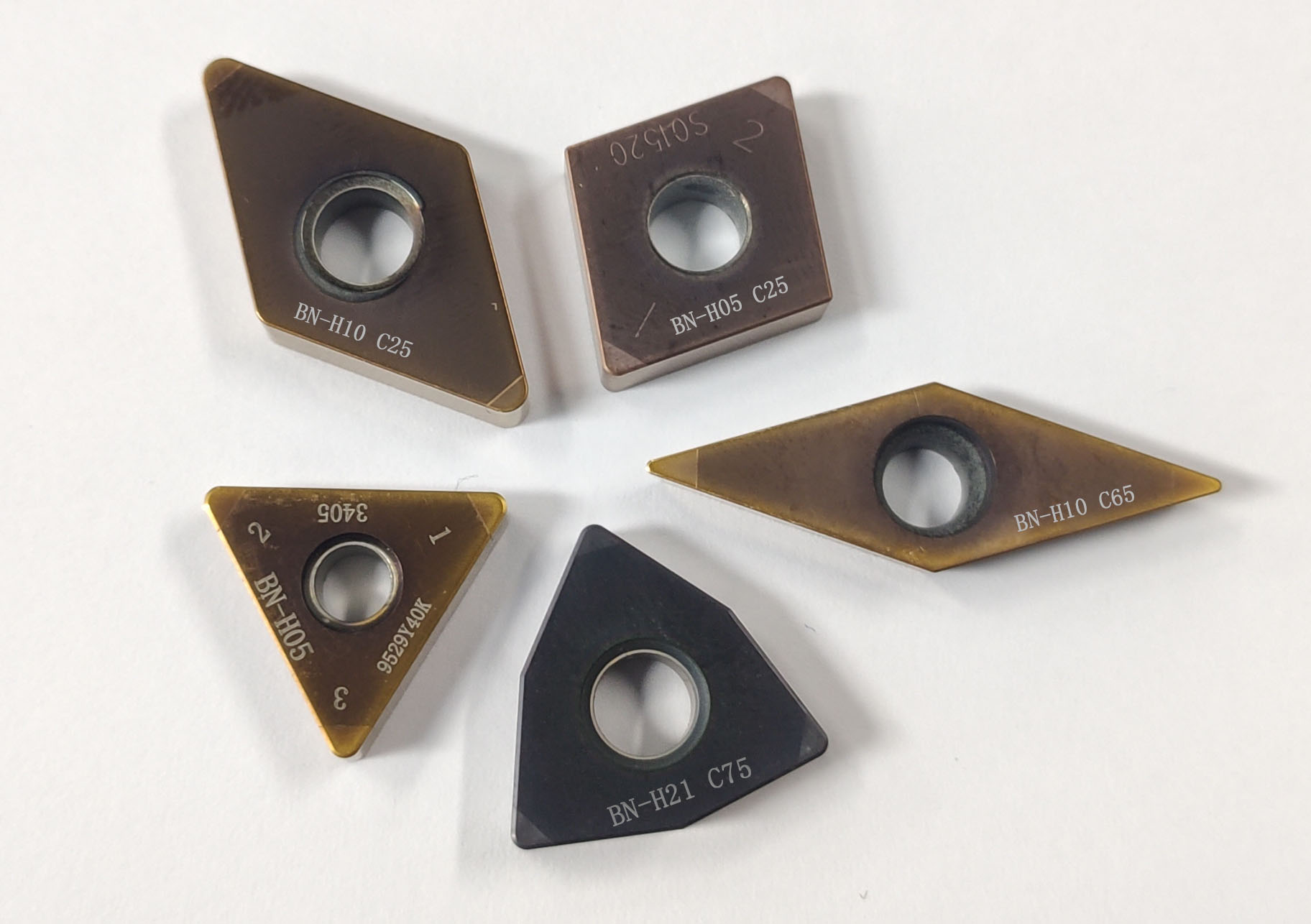

As a mass-produced part of gears, companies not only require high precision and high roughness, but also have extremely high requirements for efficiency and cost. Therefore, Halnn has launched three types of single-sided welding CBN inserts, double-sided welding CBN inserts and coated double-sided single/double-sided welding CBN inserts for users to choose from.

Introduction of coated CBN inserts material and coating for gear fine boring inner hole

According to the situation of the inner hole and end face of the gear, there are three processing conditions: continuous processing, medium interrupted processing and heavy interrupted processing. Among them, the continuous processing condition is that there is no keyway or oil hole on the surface, which is a continuous surface. BN-H05 material can be used for high-speed cutting and can meet the roughness requirements within Ra0.4; BN-H10 is suitable for medium intermittent machining, there is a small keyway, and small oil holes will not break up. Heavy interrupted machining is the most demanding, not only requires high hardness and wear resistance, but also has extremely high impact toughness to prevent the tool from chipping. For this type of material, BN-H21 is selected for impact resistance.

Halnn recommends three coatings to improve the performance of the tool, namely C25, C65, C75, these three numbers represent different coating colors, and the coating performance is also different. Among them, C25 coating is light gray, which is a moderate material and suitable for continuous processing-medium interrupted processing. C65 coating is golden yellow, suitable for ultra-high-speed processing, continuous processing, extending tool life. C75 coating is gray-brown, suitable for cutting at medium and low speeds and has strong impact and strong break working conditions of continued processing.

If the gear inner hole has multiple oil holes, you can choose BN-H21 or BN-H21 C75 for processing. If the gear end face is continuous, you can choose BN-H05 or BN-H05 C65. If the gear end face has small grooves Or for a small hole, you can choose BN-H10 or BN-H10 C25. Of course, this is not an absolute combination. The tool engineer will adjust the coating material according to the customer's on-site requirements to meet the customer's production needs.

Cases of finishing boring gear inner hole with coated CBN inserts

Workpiece: Planetary wheel

Material: 20CrMnTi

Hardness: HRC58-62

Processing part: end face, inner hole (medium intermittent)

Roughness requirements: end surface Ra1.6, inner hole Ra0.6 (two-cut processing)

Tool material: BN-H05 C65 CNGA120404

Cutting parameters: Vc=166, Ap=0.05, Fr=0.065

Cutting method: dry cutting

Conclusion: Compared with other brand of coated CBN tools, the tool life of BN-H10 C65 coated CBN inserts has increased by 1.5 times

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone