The hardness of high-hardness steel is generally around HRC60, and it has the characteristics of poor plastic deformation, large cutting resistance and high cutting temperature during processing. Due to the low hardness of the tool material, there are often problems such as difficult cutting, rapid wear, and frequent tool changing. For these, Halnn tools has launched some inserts grades, and the recommended materials are as follows

Insert Grade | Suited Materials | Machining Type | Typical Application |

BN-S20 | Hardened Steel, Heat and abrasive resistant steel, High manganese steel | Roughing, Semi-Finishing | HSS Rolls, Ball Screw, Wind Power Bearings |

BN-S200 | Hardened Steel, Superalloy | Finishing | Wind Power Bearings |

BN-H10 | Hardened Steel | Finishing | Bearings, Gears, Gear Shaft, High hardness component |

BN-H21 | Hardened Steel | Finishing | Bearings, Gears, Gear Shaft, Mold,ect. |

Rough milling: Recommend Halnn grade BN-S20, It has the characteristics of high strength, strong impact resistance and good toughness, which can effectively solve the problems of large cutting amount and large vibration of high-hardness steel parts.

Finishing milling: due to strict dimensional tolerances and high finish requirements, the tool material BN-H10 with good hardness, wear resistance and high temperature resistance is preferred to realize the hard cutting process and greatly improve the processing efficiency. The surface finish of the processed high-hardness steel parts is Ra0.4-Ra0.8, and the dimensional stability is good.

If there is interrupted cutting, BN-H21 is preferred, which has high hardness, good wear resistance, strong impact resistance, and does not chip in heavy interrupted cutting.

Machining material | Recommended cutting parameters | CBN insert Grade | ||

Cutting speed VC(m/min) | Cutting Depth ap (mm) | Feed Rate Fr(mm/r) | ||

Hardness Steel (Hardness≥HRC45) | 50-150(Roughing) | 1-10 | 0.1-0.5 | BN-S20 |

90-250(Finishing) | ≤1 | 0.05-0.35 | BN-H10, BN-H21, BN-S200 | |

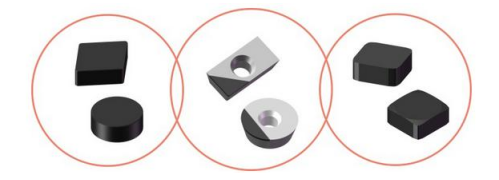

Commonly used CBN milling insert models for hard milling high-hardness steel parts

Solid CBN milling inserts

Rough milling inserts, inserts without holes, need to be matched with a special milling cutter. Such as SNFN120712, SNFN120716, matching TSM series rough milling cutters; CNFN120712, CNFN120716, matching TZM series milling cutters; RNFN120600, matching TRM series face milling cutters.

Precision milling inserts

PCBN finishing milling inserts: can be used together with general common tool cutters, such as RDMW120400, RDMW160400, RPMW080200, RPMW100300, RPMW10T300, RPMW120400; APMT160404, APMT160408; SEET12T3PF, SEHT1204AFFN, etc.

Solid CBN milling inserts: need to be matched with special milling cutters, such as SNEN0903ENS, SNEN0904ENS, SNEN1204ENS, SNEN1207ENS, SNEN120712, SNEN19T6ENS, SNEX1203ZZ, SNEX1204ZZ; RNEN090300, RNEN090400, RNEN120700, etc.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone