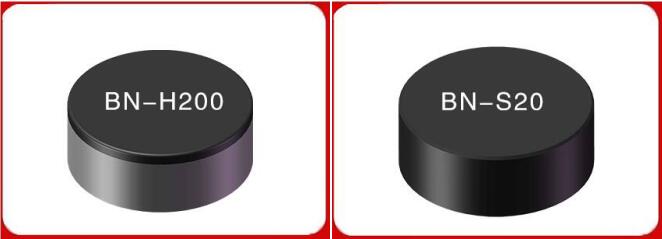

1. Solid CBN inserts

Most of the hardened steel workpieces have a small margin and are usually processed with welded CBN inserts (BN-H05, BN-H10), but some parts such as wind turbine bearings, slewing bearings, and ball screw shaft heads have machining allowances greater than 1mm. When using solid CBN inserts BN-S20 and BN-H200, the cutting effect is better.

Commonly used models are: RNGN090300, RNGN120400, SNGN090404, CNGN120708, RCGX120700.

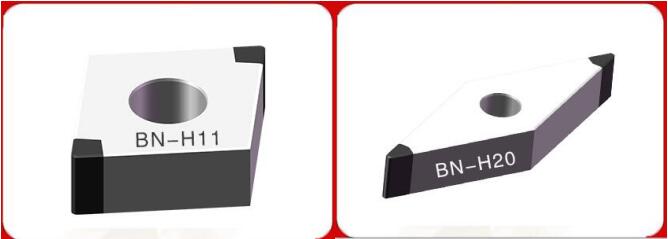

2. Brazed CBN inserts

Brazed CBN inserts are more economical, and are mostly used when the finish and accuracy requirements are not high, such as the finish requirement of Ra0.8. At this time, the brazed CBN inserts BN-H11 and BN-H20 can be selected for cutting hardened steel.

Commonly used models are: BN-H11 DNGA160404, CNGA120408, BN-H20 VNGA160404

3. PCBN inserts

PCBN inserts are mainly used for high finishing and high precision, such as finishing requirements Ra0.4, accuracy requirements within 2μm, using PCBN inserts BN-H05, BN-H10, BN-H21 for cutting hardened steel with high efficiency.

Commonly used models are: BN-H05 CNGA120408, TNGA160404, CCGW09T304, VNGA160408

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone