Difficulties in processing rolls

1. High hardness for rolls. The hardness of rolls after casting is generally above HSD75, especially now more and more cemented carbide rolls/roll rings appear on the market, which are extremely hard and cannot be processed by traditional tools.

2. Low efficiency. Due to the high hardness of the heat-treated rolls, it is usually processed by grinding with traditional tools, especially large rolls with large margins and extremely low processing efficiency.

3. The tool is not wear-resistant. As-cast rolls not only have high hardness, but also often have casting defects such as sand inclusions and pores, which will cause rapid tool wear and low life, and frequent tool changes will affect normal processing.

Choice of turning inserts for processing rolls

For high-hardness rolls, the current turning tools are made of CBN and PCD. The full range of CBN is cubic boron nitride tools, and PCD tools are also diamond tools. For different materials, choose different superhard tools.

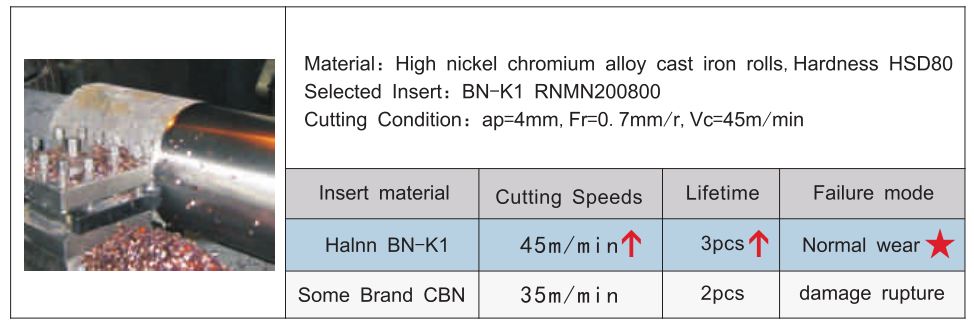

The main components of CBN inserts are formed by CBN particles (cubic boron nitride) and special ceramics and metal binders, which have high hardness at room temperature and high temperature. Tool material that has the characteristics of less chemical reaction with the material being cut. Mainly for ferrous metal materials, such as high nickel-chromium cast iron rolls, chilled cast iron rolls, nickel hard cast iron rolls, high speed steel rolls, high-boron steel rolls with large margin cutting, even if there are serious sand/pores on the surface, there is no impact. Among them, the BN-K1 material CBN turning tool is designed for high-hardness cast iron rolls, the BN-S20 material CBN turning tool is designed for high-hardness cast steel rolls, and the BN-S10 material CBN turning tool is designed for high-speed steel rolls.

PCD tools are mainly for cemented carbide rolls/roll rings. The hardness of cemented carbide rolls is too high and has exceeded the hardness range that CBN inserts can withstand. Therefore, higher PCD tools can only be used for turning processing. The CDW010 material is a general-purpose material with balanced efficiency and lifespan. If there are special requirements for a certain item, such as finish or abrasion resistance, you can use CDW302, CDW005 and other materials according to your requirements.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone