In the fast-evolving world of machining, efficiency and precision are paramount. Among the innovations that enhance these aspects are CBN (Cubic Boron Nitride) chipbreaker inserts. This article delves into the significance of CBN chipbreaker inserts, their benefits, applications, and how Halnn can provide you with top-quality solutions.

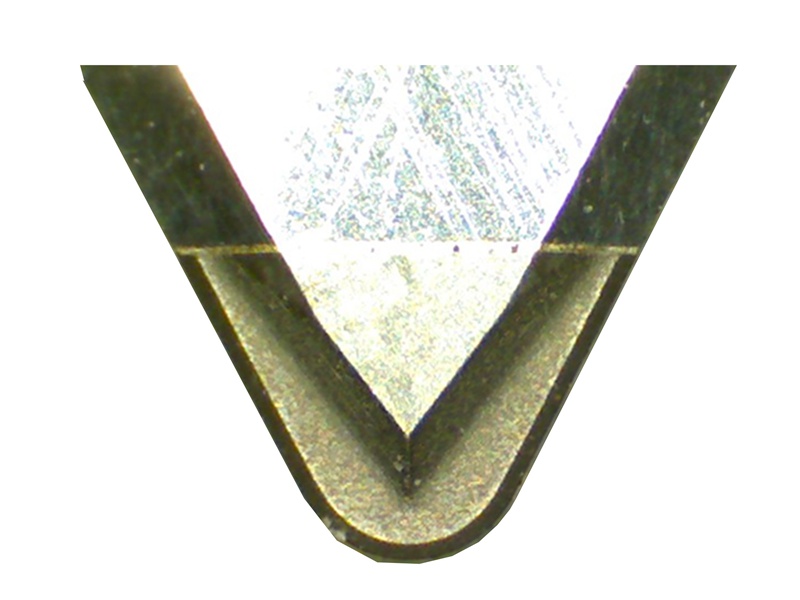

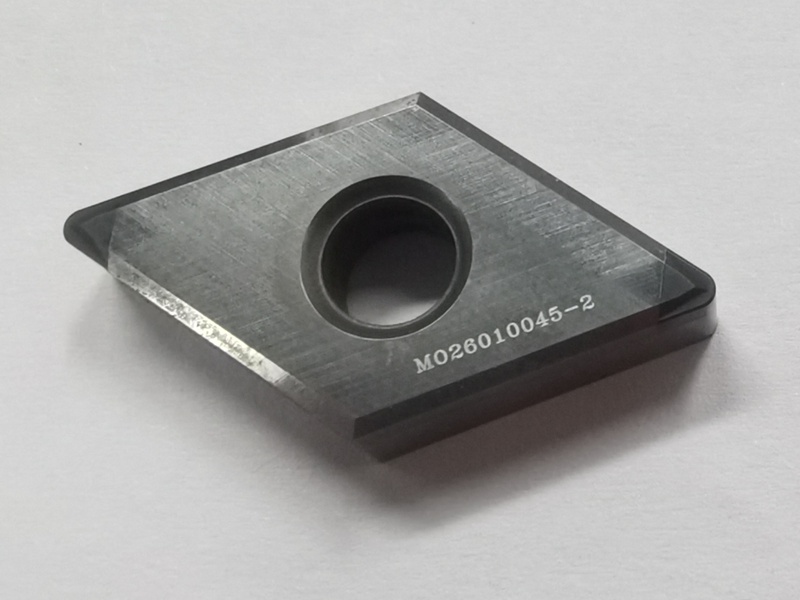

CBN chipbreaker inserts are cutting tools specifically designed to control chip formation during machining processes. Unlike standard CBN inserts, these incorporate a unique geometry that actively breaks the chips into smaller, manageable sizes. This design is crucial for maintaining smooth operations and achieving superior machining results.

The chipbreaking mechanism of CBN inserts involves the insert's geometry, which includes strategically placed notches or grooves. These features effectively interrupt the flow of chips during cutting, ensuring they are broken into smaller pieces. This not only aids in chip evacuation but also reduces the risk of entanglement and buildup, enhancing machining efficiency.

One of the primary advantages of CBN chipbreaker inserts is their ability to maintain effective chip control. By breaking chips into smaller pieces, these inserts ensure that chips are easily evacuated from the cutting zone, preventing any obstruction that could lead to tool damage or poor surface finish.

The controlled chip formation results in a smoother machining process, which translates into superior surface finish quality. Users can expect less post-machining work, leading to improved overall efficiency and reduced costs.

CBN inserts with chipbreakers are designed to withstand higher cutting speeds and feed rates. The enhanced cooling and chip removal capabilities reduce thermal stress on the tool, significantly extending tool life and reducing wear.

CBN chipbreaker inserts are versatile and suitable for various industries, including:

Automotive: Ideal for precision machining of hardened components.

Aerospace: Useful for producing intricate parts with tight tolerances.

General Manufacturing: Effective in diverse machining operations, including turning, milling, and grinding.

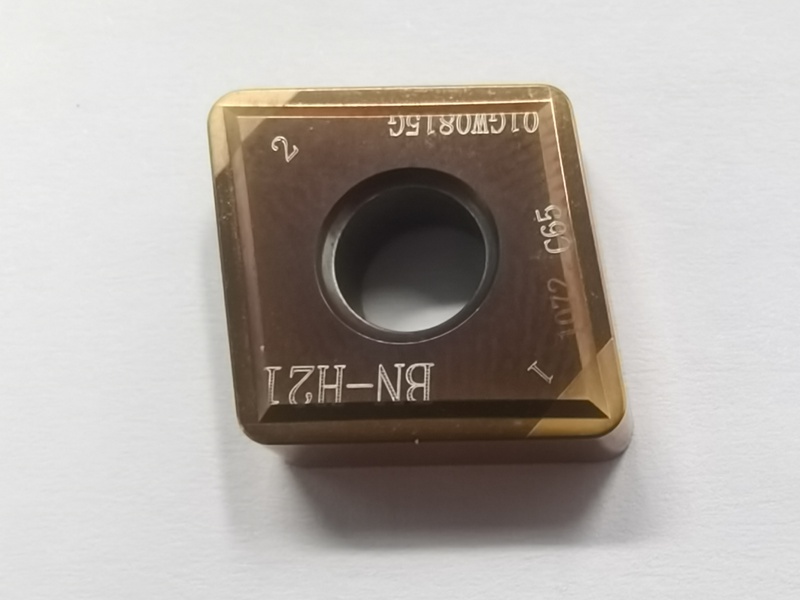

These inserts excel in applications involving hardened steel and other tough materials, making them indispensable in high-performance machining environments.

When selecting a CBN chipbreaker insert, consider the following factors:

Material Type: Ensure compatibility with the workpiece material.

Cutting Conditions: Evaluate speed, feed rate, and depth of cut to choose the optimal insert geometry.

Application Requirements: Different operations may require specific chipbreaker designs to achieve desired results.

Halnn offers a range of CBN inserts designed to meet the diverse needs of our customers, ensuring you find the perfect fit for your machining tasks.

To maximize the lifespan of your CBN chipbreaker inserts:

1. Proper Handling: Avoid dropping or mishandling inserts to prevent chipping.

2. Regular Inspections: Check for wear or damage before use to maintain optimal performance.

3. Storage Conditions: Store inserts in a clean, dry environment to prevent corrosion.

CBN chipbreaker inserts are a vital innovation in the machining industry, offering significant benefits such as improved chip control, enhanced surface finish, and extended tool life. Halnn is dedicated to providing high-quality CBN inserts that cater to the evolving needs of modern manufacturing. For more information about our products and to explore our offerings, visit Halnn’s website today!

A CBN chipbreaker insert is a cutting tool designed with specific geometries that actively break chips into smaller pieces during machining, improving chip control and evacuation.

These inserts enhance machining performance by reducing chip size, facilitating easier chip removal, and minimizing the risk of built-up edge (BUE), which leads to smoother operations and better surface finishes.

CBN chipbreaker inserts are particularly effective for machining hardened steels and other tough materials, making them ideal for applications in industries like automotive and aerospace.

The key benefits include improved chip control, enhanced surface finish quality, extended tool life, and the ability to handle higher cutting speeds and feed rates.

Consider factors such as the type of material being machined, cutting conditions (speed, feed rate), and specific application requirements to select the appropriate insert design.

To maintain optimal performance, handle inserts carefully to avoid damage, regularly inspect them for wear, and store them in a clean, dry environment to prevent corrosion.

High-quality CBN chipbreaker inserts can be purchased from Halnn, which specializes in providing reliable and effective cutting tools tailored to various machining applications. Visit our website for more information.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone