In the dynamic world of precision machining, interrupted cutting plays a crucial role in enhancing productivity and achieving superior part quality. When combined with the remarkable properties of CBN (Cubic Boron Nitride) tools, this method becomes even more effective. This article delves into the intricacies of interrupted cutting with CBN tools, highlighting their benefits, applications, and best practices, while showcasing Halnn as your trusted partner for high-quality machining solutions.

Interrupted cutting refers to a machining process where the cutting edge of the tool intermittently engages and disengages from the workpiece. This contrasts with continuous cutting, where the tool remains in constant contact with the material. Interrupted cutting is often employed in applications where features such as grooves, splines, or gears are machined, resulting in complex profiles that require precise cutting techniques.

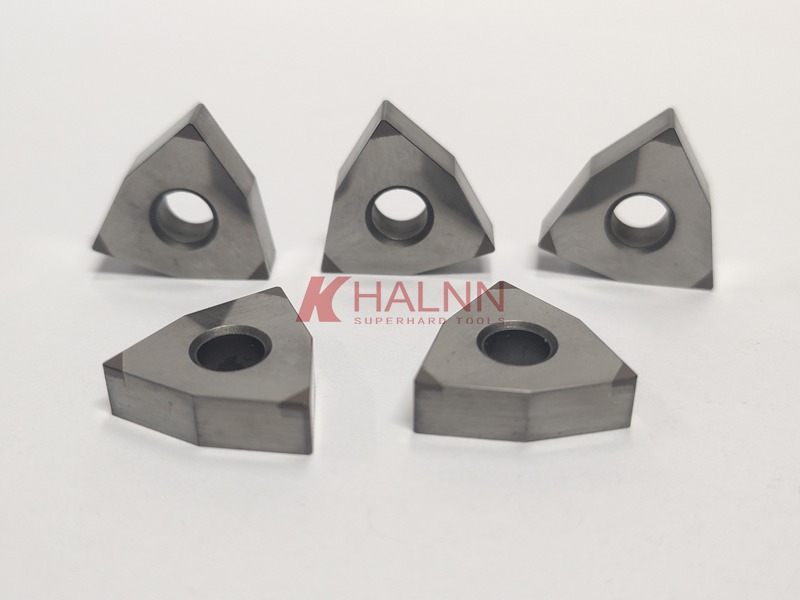

1. Superior Hardness and Wear Resistance: CBN tools are known for their exceptional hardness, making them ideal for cutting hard materials like hardened steel and superalloys. This property leads to extended tool life and fewer tool changes, ultimately boosting productivity.

2. High Thermal Stability: CBN maintains its structural integrity at high temperatures, allowing for consistent performance during interrupted cutting operations. This thermal stability prevents tool deformation and helps achieve accurate machining.

3. Improved Surface Finish: The cutting action of CBN tools results in smoother surfaces, which is critical in applications where surface quality is paramount. This advantage minimizes the need for secondary finishing processes.

4. Increased Productivity: With longer tool life and faster cutting speeds, CBN tools significantly reduce downtime and improve overall machining efficiency, making them a cost-effective choice in the long run.

CBN tools are widely used across various industries, including:

Automotive: Machining components like gears and camshafts that require high precision and durability.

Aerospace: Producing intricate parts with tight tolerances, crucial for flight safety and performance.

Manufacturing: Suitable for high-volume production of complex workpieces such as splines and keyways.

These tools excel in both turning and milling operations, demonstrating their versatility in interrupted cutting scenarios.

When selecting a CBN tool for interrupted cutting, consider the following factors:

Workpiece Material: Ensure the tool is compatible with the material being machined, especially if it is hardened or abrasive.

Cutting Conditions: Evaluate the machining parameters such as speed, feed rate, and depth of cut to select the optimal tool.

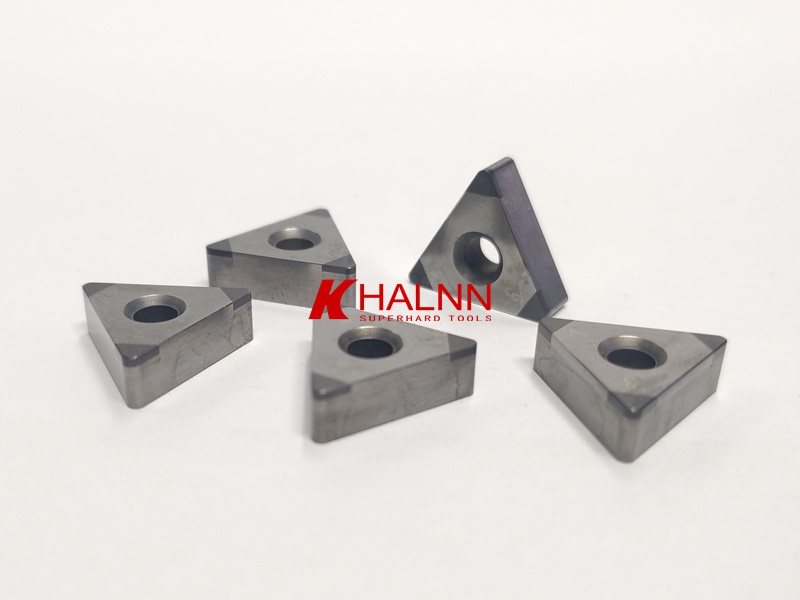

Insert Geometry: Choose the appropriate geometry and size of the CBN insert based on your specific machining requirements to enhance performance.

To maximize the effectiveness of CBN tools in interrupted cutting, adhere to these best practices:

Follow Recommended Cutting Parameters: Consult the manufacturer's guidelines for optimal speeds and feeds to ensure efficient cutting.

Proper Tool Setup: Ensure that the tool is correctly aligned and securely mounted to minimize vibration and improve cutting accuracy.

Use of Coolants: While CBN tools often require minimal cooling, using appropriate lubrication can further enhance tool life and performance.

While CBN tools offer numerous advantages, some challenges may arise, including:

Tool Wear: Regularly inspect inserts for wear and replace them as needed to maintain machining quality.

Chipping or Breakage: Ensure proper alignment and adhere to cutting parameters to reduce the risk of chipping or breakage during operations.

Interrupted cutting with CBN tools involves a machining process where the cutting edge of the CBN insert intermittently engages and disengages from the workpiece, making it ideal for creating complex shapes like grooves and splines.

CBN tools offer superior hardness, high thermal stability, improved surface finish, and increased productivity. Their durability leads to longer tool life and reduced downtime during machining operations.

CBN tools are particularly effective for machining hard materials such as hardened steel, superalloys, and cast iron, making them suitable for a variety of industrial applications.

Consider factors such as the workpiece material, cutting conditions (speed, feed rate, depth of cut), and the geometry of the CBN insert. Selecting the appropriate tool ensures optimal performance and results.

Follow the manufacturer's guidelines for optimal speeds and feeds based on the specific application and material being machined. Proper parameters help achieve efficient cutting and prolong tool life.

Yes, CBN tools are versatile and can be effectively used in both turning and milling operations for interrupted cutting applications, providing excellent performance across different machining tasks.

Common challenges include tool wear, chipping, and breakage. Regular inspection and adherence to recommended cutting parameters can help mitigate these issues.

To maximize performance, ensure proper tool setup, follow recommended cutting parameters, and use appropriate lubrication or cooling strategies, even though CBN tools typically require minimal cooling.

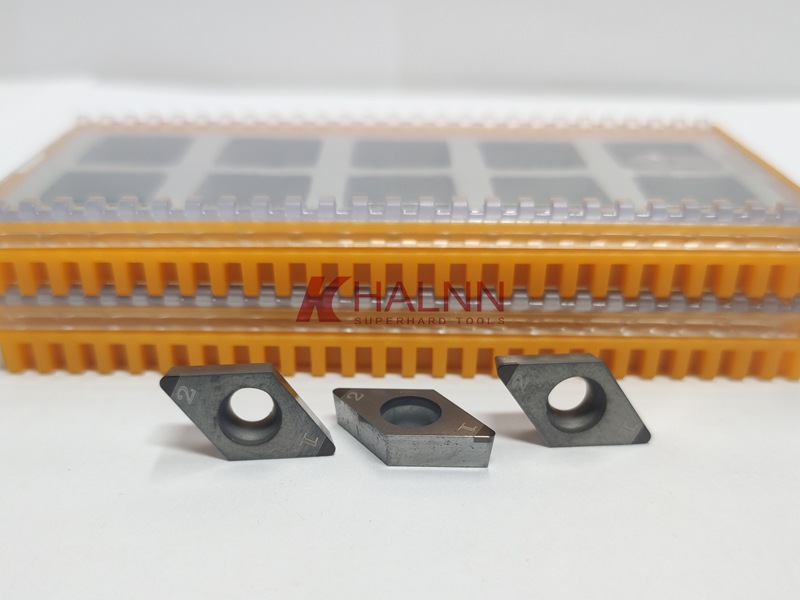

High-quality CBN tools designed for interrupted cutting can be purchased from Halnn, which specializes in providing advanced cutting solutions tailored to meet specific machining needs.

Regularly inspect CBN inserts for wear and damage, replace them as needed, and ensure that the tool is securely mounted and properly aligned to maintain machining accuracy.

Interrupted cutting with CBN tools offers significant advantages in terms of productivity, precision, and tool longevity. By leveraging the unique properties of CBN, manufacturers can achieve superior results in their machining processes. For high-quality CBN tools tailored to your interrupted cutting needs, look no further than Halnn, where we are dedicated to providing innovative solutions that enhance your machining capabilities.

Explore Halnn’s extensive range of CBN tools designed for interrupted cutting! Contact us today for inquiries or to request a quote, and discover how our advanced cutting tools can elevate your machining operations.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone