In the competitive world of engraving, having the right tools is essential for achieving precision, efficiency, and quality. Halnn, a leader in the cutting tools industry, offers top-of-the-line Rolls PCD Engraving Tools that cater to the diverse needs of professionals across various sectors. This article delves into the features, benefits, applications, and reasons to choose Halnn’s Rolls PCD engraving tools, providing valuable insights for users and promoting Halnn’s exceptional offerings.

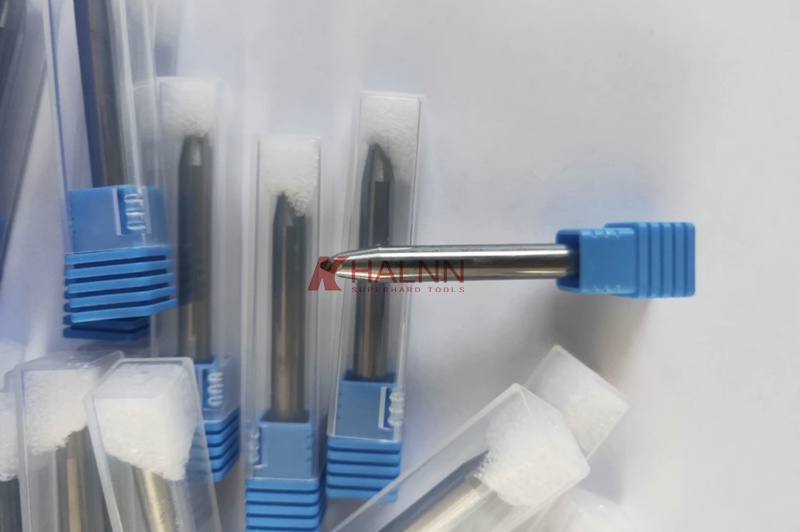

Rolls PCD Engraving Tools are specialized instruments designed for high-precision engraving applications. PCD, or Polycrystalline Diamond, is renowned for its hardness and durability, making it an ideal material for engraving tools that demand longevity and accuracy. At Halnn, we are committed to delivering superior Rolls PCD engraving tools that enhance productivity and ensure flawless results in every project.

Rolls PCD Engraving Tools are cutting-edge tools used to create intricate designs, patterns, and text on various materials. PCD, a composite of diamond crystals, offers unparalleled hardness and wear resistance, making these tools perfect for demanding engraving tasks.

PCD is composed of multiple diamond crystals fused together, providing exceptional hardness and thermal conductivity.

Halnn’s Rolls PCD engraving tools are manufactured using advanced technologies to ensure superior quality and performance.

Choosing Halnn Rolls PCD Engraving Tools offers numerous advantages that set them apart from traditional engraving tools:

PCD’s exceptional hardness ensures that the tools maintain their sharpness and effectiveness over extended periods, reducing the need for frequent replacements.

Halnn’s engineering expertise guarantees that each PCD engraving tool delivers precise and consistent results, even in the most intricate applications.

Enhanced cutting efficiency allows for faster engraving processes, minimizing downtime and increasing overall productivity.

The extended lifespan of PCD tools translates to lower long-term costs, providing excellent value for your investment.

Halnn’s Rolls PCD Engraving Tools are versatile and used across various industries for diverse applications:

Engraving components in automotive, aerospace, and machinery industries for identification, branding, and functional purposes.

Precision engraving on medical instruments and equipment for traceability and customization.

Detailed engraving on electronic components and devices to enhance functionality and aesthetics.

Creating intricate designs on jewelry, art pieces, and customized items, showcasing creativity and craftsmanship.

Halnn ensures that every Rolls PCD Engraving Tool meets the highest standards through the following key features:

Only the highest grade PCD is used, ensuring maximum hardness and wear resistance.

Ergonomically designed for optimal performance and ease of use, facilitating precise engraving.

Halnn offers tailored engraving tools to meet specific project requirements, ensuring the perfect fit for any application.

Compatible with a variety of engraving machines and systems, providing flexibility and ease of integration into existing workflows.

Proper maintenance ensures that your Rolls PCD Engraving Tools continue to perform optimally:

Remove debris and residues after each use to prevent buildup that can affect performance.

Frequently check for signs of wear, such as chipping or dullness, and replace tools as necessary.

Store tools in a clean, dry environment to protect them from moisture and contaminants.

Implement a maintenance schedule to keep tools in top condition and extend their lifespan.

Selecting the appropriate Rolls PCD Engraving Tool is crucial for achieving optimal results:

Determine the level of detail, material type, and production volume to choose the right tool.

Consider factors such as size, shape, and PCD grade to match your specific application needs.

Balance the initial cost with the long-term benefits of durability and performance.

Consult with Halnn’s experts to receive recommendations tailored to your engraving projects.

Halnn has a strong reputation for delivering high-quality Rolls PCD Engraving Tools. Here are some success stories from our satisfied customers:

“Halnn’s PCD engraving tools have transformed our production line. The precision and durability are unmatched, and our output quality has significantly improved.” – Automotive Manufacturer

“We rely on Halnn’s PCD tools for our medical device engraving. The consistency and accuracy are critical, and Halnn delivers every time.” – Medical Equipment Company

“The customization options offered by Halnn allowed us to achieve the exact specifications needed for our specialized machinery parts. Highly recommend their PCD engraving tools.” – Industrial Machinery Firm

Rolls PCD engraving tools are specialized cutting tools made from Polycrystalline Diamond (PCD), designed for precise and durable engraving on various materials such as metals, ceramics, and plastics. These tools are specifically used in industrial applications where high precision and long tool life are critical.

Rolls PCD engraving tools offer several advantages:

High durability due to the hardness of PCD, providing longer tool life.

Superior precision for creating fine, detailed engravings.

Wear resistance, which ensures consistent performance over long periods.

Reduced downtime as the tools need less frequent replacement, improving efficiency in production.

Rolls PCD engraving tools can engrave a wide range of materials, including:

Hardened steel

Non-ferrous metals (aluminum, copper, etc.)

Ceramics

Plastics

Composites

Their versatility makes them ideal for industries like automotive, aerospace, electronics, and more.

Rolls PCD engraving tools offer greater hardness and wear resistance compared to carbide tools. While carbide tools are more affordable initially, PCD tools provide longer tool life and higher precision, making them more cost-effective in the long run for high-volume or critical applications.

Yes, Rolls PCD engraving tools are ideal for high-speed machining. PCD’s excellent thermal conductivity reduces heat buildup, enabling the tools to maintain performance and precision even at high speeds, which is essential for efficient industrial engraving.

The lifespan of Rolls PCD engraving tools depends on the material being engraved and the machining conditions. However, due to the extreme hardness and durability of PCD, these tools typically last significantly longer than traditional tools like carbide, especially in demanding applications.

While PCD tools are known for their long-lasting sharpness, re-sharpening is possible, though it requires specialized equipment and expertise. It is often more cost-effective to replace the tool when the edge becomes dull after extended use.

Industries that require precision and durability in engraving benefit the most from Rolls PCD engraving tools, including:

Automotive (engraving parts, labels, and identification)

Aerospace (marking critical components)

Medical (engraving medical devices)

Electronics (engraving micro-components)

When choosing Rolls PCD engraving tools, consider:

Material type: Ensure the tool is suitable for the material being engraved.

Engraving detail: Select the right tool geometry based on the level of detail required.

Production volume: For high-volume engraving, PCD tools are preferred due to their longevity and consistent performance.

Machine compatibility: Verify that the tool is compatible with your engraving machine.

To maintain optimal performance, regularly clean the tools to remove debris, inspect for wear, and store them properly in a dry, clean environment. Routine maintenance will extend their lifespan and ensure consistent engraving quality.

Halnn’s Rolls PCD Engraving Tools are engineered to deliver unmatched precision, durability, and efficiency, making them the ideal choice for professionals across various industries. Whether you are involved in industrial manufacturing, medical device production, or artistic engraving, Halnn provides the tools you need to achieve excellence.

Investing in Halnn’s Rolls PCD engraving tools means choosing quality, reliability, and superior performance. Elevate your engraving projects with Halnn and experience the difference that premium PCD tools can make.

Contact Halnn today to learn more about our Rolls PCD engraving tools and discover how we can support your engraving needs with our expert solutions.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone