In the demanding world of manufacturing, efficiency and precision are critical. Rolls, particularly those made from hardened materials, require specialized tools to meet stringent quality standards and reduce operational costs. This is where Halnn's Rolls CBN inserts come into play, offering superior performance for machining hardened rolls. In this article, we will delve into the specifics of Rolls CBN inserts, why they are essential for machining applications, and how Halnn's Rolls PCBN inserts can significantly enhance your productivity.

CBN (Cubic Boron Nitride) is a synthetic material known for its hardness, second only to diamond. When it comes to machining hard materials like hardened steel, cast iron, or chilled rolls, CBN inserts provide unmatched durability and cutting performance. Unlike traditional carbide tools, which can wear down quickly in such conditions, CBN inserts maintain their cutting edge for extended periods, even under extreme temperatures and pressures.

Machining rolls presents unique challenges due to their high hardness (often exceeding HRC 50), toughness, and the need for precise surface finishes. These challenges demand tools that can withstand high-speed operations while maintaining a consistent cutting edge. Halnn's Rolls CBN inserts excel in such conditions, ensuring smooth operations and reduced downtime.

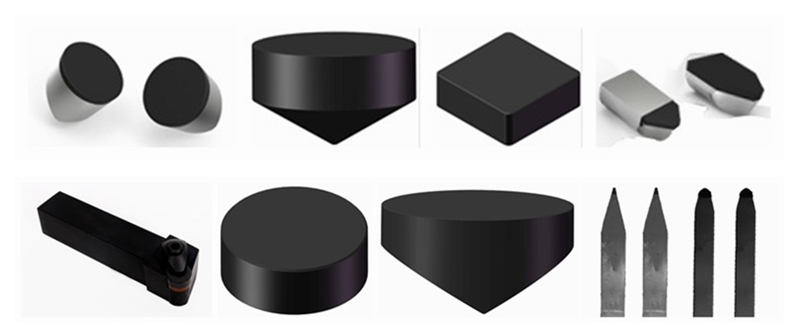

There are various types of Rolls CBN inserts, each designed for specific applications and materials.

Solid CBN Inserts: These inserts are made entirely from CBN material and are ideal for continuous cutting operations where tool longevity is paramount.

Coated CBN Inserts: Coated with additional materials, these inserts enhance cutting performance, particularly in interrupted cutting conditions often encountered in rolls machining.

Composite CBN Inserts: These feature a CBN cutting edge fused to a carbide substrate, offering a balance between cost and performance for heavy-duty applications.

Halnn’s Rolls PCBN Inserts are available in various geometries, designed to maximize material removal rates, reduce cycle times, and improve surface finishes in rolls machining.

When compared to traditional cutting tools, CBN inserts offer a host of benefits that make them the preferred choice for rolls machining:

1. Extended Tool Life: CBN’s wear resistance is far superior to that of carbide or ceramic tools. Halnn’s Rolls CBN inserts can last up to 10 times longer, especially when machining hardened rolls, reducing the frequency of tool changes and machine downtimes.

2. High Cutting Speeds: CBN inserts enable significantly higher cutting speeds without compromising tool life. This leads to faster machining cycles and increased production efficiency.

3. Improved Surface Finishing: One of the key challenges in machining rolls is achieving a high-quality surface finish. Halnn’s CBN inserts ensure smooth finishes, even in hard-to-machine materials like chilled or forged rolls.

4. Cost-Effectiveness: While CBN inserts may have a higher upfront cost than traditional tools, their extended tool life and ability to maintain performance at high cutting speeds result in lower overall tooling costs and increased productivity.

Rolls CBN inserts find their place in a variety of industries, including:

Steel Production: In steel manufacturing, rolls are subjected to constant wear and tear. CBN inserts ensure longevity and precision when machining hardened rolls used in steel mills.

Automotive Industry: In heavy-duty manufacturing, precision components require hard turning of materials like steel or iron rolls. Halnn’s Rolls PCBN inserts are ideal for this purpose, offering long-lasting cutting edges and superior surface finishes.

Power Generation: Rolls used in power plants are often made from high-strength alloys that require high-performance tools like CBN inserts for precision machining.

A case study involving a leading steel manufacturer demonstrated that by switching to Halnn's Rolls CBN inserts, they were able to extend tool life by 300% and reduce production downtime by 25%. This resulted in a significant reduction in overall operational costs while maintaining high-quality surface finishes.

When it comes to selecting the best CBN inserts for rolls machining, Halnn offers a wide range of solutions designed to meet the specific needs of your application.

Halnn has a strong reputation in the industry for producing high-quality Rolls CBN inserts and Rolls PCBN inserts. Our products are rigorously tested to ensure they meet the highest standards of performance, durability, and precision. Whether you are machining hardened steel rolls or dealing with interrupted cutting, Halnn’s CBN inserts are engineered to deliver top-tier performance.

To get the most out of your Rolls CBN inserts, it is essential to follow best practices in machining parameters and tool maintenance:

1. Machining Parameters: For optimal performance, use the appropriate cutting speed, feed rate, and depth of cut based on the material hardness and tool type. Halnn’s experts recommend a cutting speed of 100-150 m/min for hardened steel rolls.

2. Insert Maintenance: Regularly inspect and rotate the inserts to ensure consistent performance. Keeping a strict maintenance schedule can extend the life of your CBN inserts.

3. Addressing Common Challenges: In interrupted cutting, using a composite Rolls CBN insert can reduce the risk of edge chipping and improve tool life.

Rolls CBN inserts are cutting tools made from cubic boron nitride (CBN) material, specifically designed for machining rolls made from hardened steel, cast iron, or other tough materials. They offer high hardness, wear resistance, and thermal stability, making them ideal for heavy-duty machining applications.

Rolls CBN inserts have a much longer tool life compared to carbide inserts, especially when machining hardened materials. They maintain their cutting edge at high temperatures, enable faster cutting speeds, and provide superior surface finishes, reducing the need for secondary operations.

Yes, Rolls CBN inserts are highly effective for interrupted cutting operations, especially when combined with proper machining parameters. Halnn’s composite CBN inserts, for instance, are specifically designed to withstand the stresses of interrupted cuts, reducing the risk of chipping or tool failure.

The optimal cutting speed depends on the material hardness and specific insert type, but generally, cutting speeds for Rolls CBN inserts range between 100 to 200 m/min when machining hardened steel rolls. Halnn provides detailed guidelines for each type of CBN insert to maximize performance.

Although CBN inserts have a higher initial cost compared to traditional carbide tools, their extended tool life, ability to handle high-speed machining, and reduced tool changes make them more cost-effective in the long run, particularly in applications like machining hardened rolls.

Rolls CBN inserts are primarily designed for machining hardened rolls, such as those made from hardened steel, cast iron, or chilled alloys. However, their application should be evaluated based on the material and hardness of the roll. Halnn’s experts can help recommend the appropriate CBN insert for your specific roll machining requirements.

The right choice depends on several factors, including the roll material, machining conditions, and whether the operation involves continuous or interrupted cutting. Halnn offers a variety of CBN inserts tailored for different applications, and our experts can guide you in selecting the best option for your specific needs.

The tool life of Rolls CBN inserts varies depending on the material being machined and the cutting conditions. In general, Halnn’s CBN inserts provide significantly longer tool life than carbide tools, especially when used in high-hardness materials. Under optimal conditions, tool life can be up to 10 times longer than carbide inserts.

While Rolls CBN inserts are compatible with standard CNC machines, achieving optimal performance requires proper setup of machining parameters such as cutting speed, feed rate, and depth of cut. Halnn provides detailed recommendations to ensure your machine setup maximizes the potential of CBN inserts.

Halnn’s Rolls CBN inserts are engineered for superior performance in rolls machining. They undergo rigorous testing to ensure durability, precision, and long tool life. Our expertise in the field, coupled with a wide range of CBN solutions, makes Halnn a reliable partner for all your rolls machining needs.

Halnn's Rolls CBN inserts offer unparalleled advantages for machining rolls, particularly hardened materials. With their extended tool life, superior cutting performance, and ability to handle high-speed operations, Halnn’s Rolls PCBN inserts are the perfect solution for companies looking to optimize their production processes.

For more information on how Halnn can support your machining needs, or to request a quote, please contact us today.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone