In the world of precision machining, Rolls ring notching tools play a crucial role in ensuring the accuracy and efficiency of ring notching processes. At Halnn, we specialize in delivering high-quality Rolls ring notching tools that cater to diverse industrial needs. Our tools are designed to provide exceptional performance and reliability, setting industry standards for precision and durability.

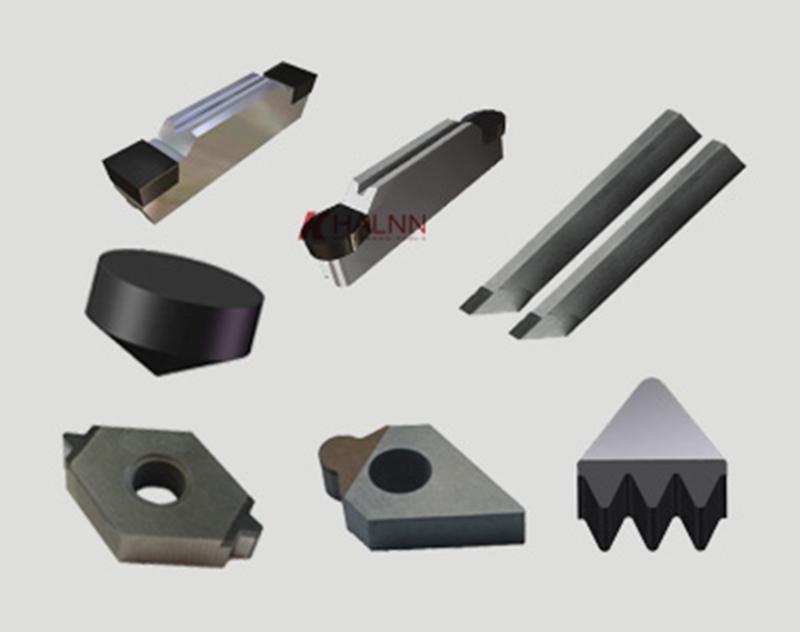

Rolls ring notching tools are specialized cutting tools used to create notches or grooves in ring-shaped components. These tools are essential for applications requiring high precision and consistency. Key features of Rolls ring notching tools include:

Precision Cutting: Designed to achieve precise notching with minimal deviation.

Durability: Made from high-grade materials to withstand wear and tear.

Versatility: Suitable for a wide range of applications and materials.

1. Manual Ring Notching Tools: Ideal for smaller-scale operations and precise manual adjustments.

2. Automatic Ring Notching Tools: Suitable for high-volume production with automated processes.

3. Custom Ring Notching Tools: Tailored to specific requirements for unique applications.

Rolls ring notching tools are used across various industries, including automotive, aerospace, and manufacturing. The benefits of using high-quality notching tools from Halnn include:

Enhanced Accuracy: Achieve precise notching that meets stringent quality standards.

Increased Efficiency: Reduce downtime and increase productivity with reliable tools.

Cost-Effectiveness: Minimize material waste and extend tool life with durable solutions.

Automotive Industry: Halnn’s Rolls ring notching tools have been instrumental in producing high-precision components for automotive applications, resulting in significant improvements in manufacturing efficiency and product quality.

Aerospace Industry: Our tools have helped aerospace manufacturers achieve the exact tolerances required for critical components, ensuring safety and performance.

The functionality of Rolls ring notching tools involves a precise cutting mechanism designed to create notches or grooves in ring-shaped workpieces. The process typically includes:

1. Tool Setup: Positioning the tool accurately on the workpiece.

2. Cutting Action: Utilizing sharp, high-quality inserts to perform the notching.

3. Finishing: Ensuring smooth edges and precise dimensions.

Compared to other notching tools, Rolls ring notching tools offer superior precision and durability. Unlike general-purpose notching tools, Rolls tools are specifically engineered to handle the unique demands of ring notching, providing enhanced performance and reliability.

Choosing the right Rolls ring notching tool involves considering factors such as:

Material Compatibility: Ensure the tool is suitable for the material of the workpiece.

Size and Specification: Match the tool size and specification to the application requirements.

Precision Requirements: Select tools that meet the necessary accuracy and tolerance levels.

At Halnn, we offer a range of Rolls ring notching tools designed to meet diverse needs. Our experts are available to help you select the best tool for your specific application, ensuring optimal performance and value.

Proper maintenance is crucial for extending the life of your Rolls ring notching tools. Follow these tips:

Regular Cleaning: Remove debris and residue after each use.

Proper Storage: Store tools in a clean, dry environment.

Inspection: Regularly check for wear and replace inserts as needed.

Address common issues such as tool wear or performance decline by following maintenance guidelines and using high-quality inserts from Halnn.

Halnn continuously invests in research and development to advance our Rolls ring notching technology. Recent innovations include:

Enhanced Materials: Development of more durable and wear-resistant tool materials.

Improved Design: Advances in tool design for increased precision and efficiency.

Stay tuned for upcoming advancements that will further enhance the performance and capabilities of our Rolls ring notching tools.

A: Our tools are designed to work with a variety of materials, including metals and alloys, depending on the specific tool and application.

A: Consider factors such as material type, required precision, and production volume. Contact Halnn’s experts for personalized recommendations.

A: Lifespan varies based on usage and maintenance. Regular care and using high-quality inserts can extend tool life.

Halnn is committed to providing the highest quality Rolls ring notching tools, designed to meet the precise demands of modern manufacturing. With our extensive expertise and innovative solutions, we ensure that our tools deliver exceptional performance and reliability.

For more information on Halnn’s Rolls ring notching tools or to request a consultation, contact us today. Explore our range of products and discover how we can support your precision machining needs.

Our website: https://www.halnncbn.com/

Email: halnntools@halnn-group.com

Whatsapp/ Wechat: +8613271562251

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone