In today’s highly competitive manufacturing environment, selecting the right cutting tools and optimizing machining parameters are essential for maximizing productivity, reducing costs, and achieving high-quality results. Ceramic inserts, particularly those from Halnn, are among the most efficient cutting tools for hard materials. One critical parameter that affects the performance of ceramic inserts is cutting speed.

This article will explore the importance of cutting speed when using ceramic inserts, factors influencing it, and the benefits of optimizing it for various machining operations. Our goal is to provide you with valuable insights while showcasing how Halnn's ceramic inserts can elevate your machining operations.

Cutting speed refers to the rate at which the cutting tool moves across the surface of the workpiece during the machining process, typically measured in meters per minute (m/min) or surface feet per minute (SFM). It is one of the key factors that determine the efficiency, quality, and cost-effectiveness of any machining operation.

In the context of ceramic inserts, cutting speed plays a significant role in tool life, surface finish, and material removal rate. Achieving the right balance is crucial to optimize performance and prevent tool failure.

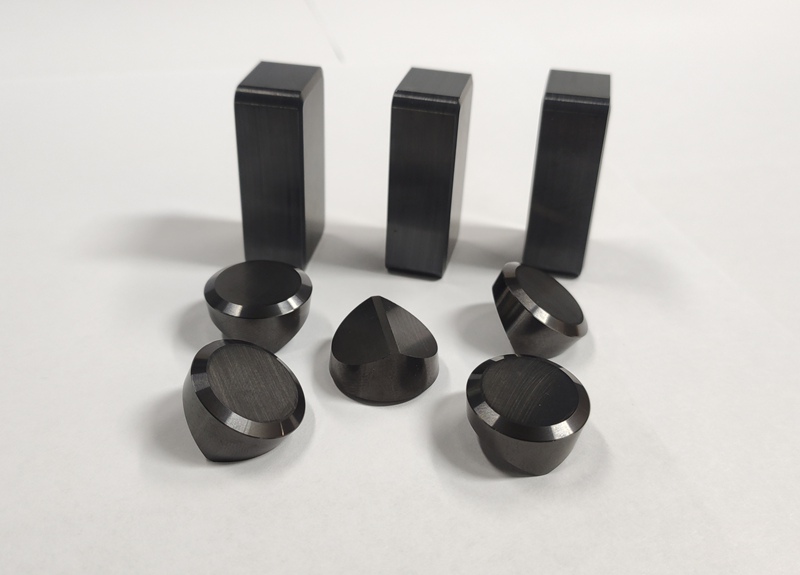

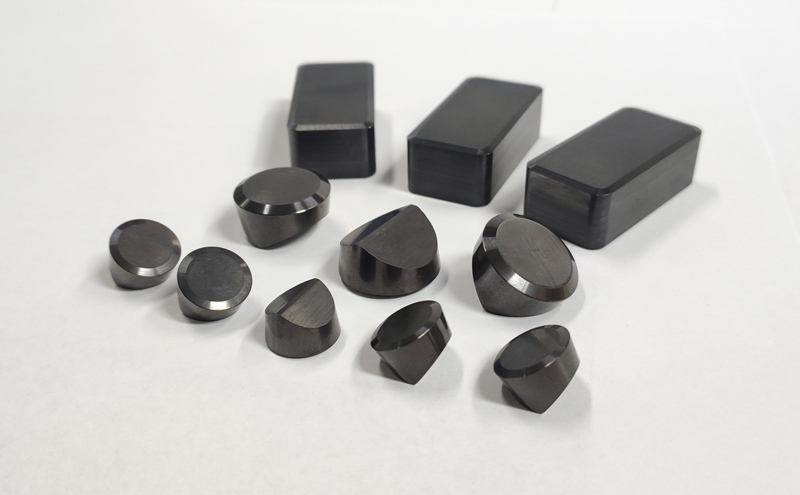

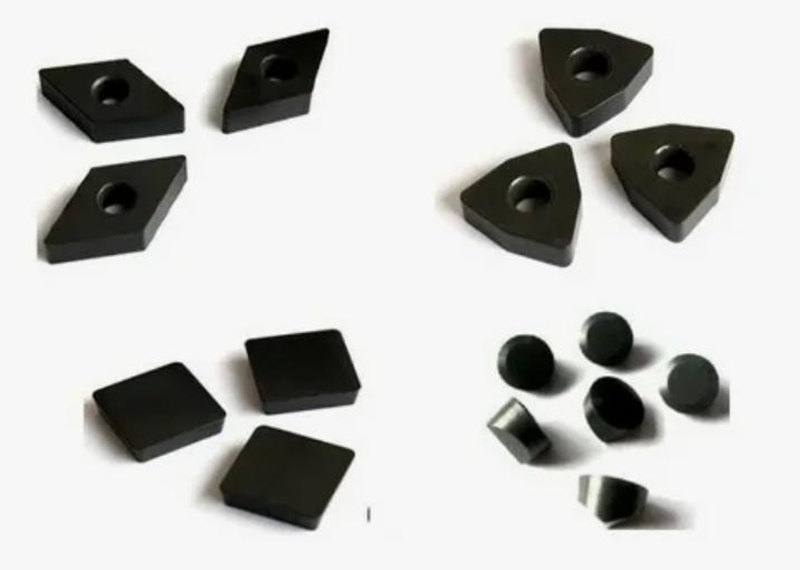

Ceramic inserts are made from advanced ceramic materials, which offer superior hardness and wear resistance compared to traditional carbide tools. They excel in high-speed machining applications, particularly when cutting hard materials such as cast iron, hardened steels, and superalloys.

Halnn's ceramic inserts are designed for demanding applications that require high-performance cutting tools. These inserts provide enhanced wear resistance and thermal stability, making them ideal for machining at high speeds.

Several factors influence the optimal cutting speed when using ceramic inserts. Understanding these factors is key to achieving the best results:

1. Material Being Machined: Different materials have varying levels of hardness, toughness, and thermal properties. For example, cutting hardened steel requires lower cutting speeds than cast iron due to its higher resistance to deformation.

2. Tool Geometry: The geometry of the ceramic insert, including rake angle, relief angle, and nose radius, plays a significant role in determining the appropriate cutting speed. Proper tool design ensures effective chip formation and reduces cutting forces.

3. Coolant Use: The use of coolants can influence cutting speed by reducing heat buildup during machining. However, ceramic inserts are typically used in dry machining, and the cutting speed must be adjusted to account for the absence of coolant.

4. Machine Capabilities: The stability and rigidity of the machine tool directly affect the cutting speed. Machines with higher spindle speeds and more stable structures can support higher cutting speeds, maximizing the performance of ceramic inserts.

5. Specific Applications: Different applications such as roughing, finishing, or interrupted cutting will require adjustments in cutting speed to achieve optimal results.

Achieving the best performance from Halnn’s ceramic inserts depends on selecting the correct cutting speed for the material being machined. Below is a general guideline for recommended cutting speeds based on different materials:

Cast Iron (Grey/ Ductile): 800-1200 m/min (2624-3937 SFM)

Hardened Steel (HRC 45-65): 150-300 m/min (492-984 SFM)

Nickel-Based Alloys: 300-500 m/min (984-1640 SFM)

These recommendations may vary depending on tool geometry, machine capability, and specific cutting conditions. Halnn’s experts are always available to assist with selecting the ideal cutting speed for your application.

When the cutting speed is optimized for ceramic inserts, manufacturers can expect several benefits that improve overall machining efficiency:

1. Extended Tool Life: Optimizing cutting speed helps reduce heat generation and tool wear, significantly extending the life of the ceramic insert.

2. Improved Surface Finish: Correct cutting speeds minimize vibration and chatter, resulting in a smoother surface finish and higher-quality parts.

3. Increased Productivity: By operating at higher cutting speeds, ceramic inserts enable faster material removal rates, reducing cycle times and increasing overall productivity.

4. Cost Savings: With optimized cutting speeds, tool life is extended, and machining times are reduced, leading to lower overall costs.

Using ceramic inserts at high cutting speeds can pose challenges, such as tool chipping, premature wear, or difficulty achieving the desired surface finish. To overcome these challenges:

Monitor Tool Wear: Regularly inspect the tool for signs of wear, and adjust cutting speed accordingly to prolong tool life.

Optimize Tool Geometry: Use the appropriate tool geometry for your application to minimize cutting forces and improve performance.

Adjust Machining Parameters: Fine-tune feed rates, depth of cut, and cutting speed to achieve the best balance between tool life and productivity.

Halnn has been at the forefront of innovation in the ceramic insert industry, offering a wide range of high-performance tools for machining hard materials. Our ceramic inserts are engineered to withstand extreme conditions, ensuring superior wear resistance, toughness, and thermal stability.

At Halnn, we understand the importance of optimizing cutting speed for different materials and applications. Our team of experts can provide personalized recommendations to help you achieve the best possible results from our ceramic inserts.

Selecting the right cutting speed when using ceramic inserts is essential for achieving high-quality machining results, reducing costs, and maximizing productivity. Halnn's ceramic inserts are designed to perform at their best when paired with the correct machining parameters, particularly cutting speed.

If you’re looking to improve your machining operations, Halnn’s ceramic inserts are the ideal solution. Contact us today for expert guidance on optimizing your cutting speeds and to learn more about our range of high-performance tools.

The recommended cutting speed for ceramic inserts when machining cast iron typically ranges from 800 to 1200 meters per minute (m/min). This range allows for effective material removal and optimized tool life while ensuring a smooth surface finish.

Cutting speed has a significant impact on tool life. Higher speeds can increase wear rates, especially if not optimized for the material. However, ceramic inserts are designed to handle high speeds due to their thermal resistance. Setting the correct speed can extend tool life and maintain performance.

Yes, increasing cutting speed can boost productivity by reducing cycle times. However, it's essential to balance speed with tool wear. Overly high speeds without proper consideration of material properties can result in premature tool failure.

For hardened steel (typically HRC 45-65), ceramic inserts can achieve cutting speeds between 150 and 300 meters per minute (m/min). This allows for efficient machining without causing excessive tool wear.

Signs of excessive cutting speed include rapid tool wear, chipping, and poor surface finish. If these occur, it's essential to reduce the cutting speed and re-evaluate the parameters to optimize performance.

Generally, coolants are not recommended when machining with ceramic inserts, especially at high speeds. Ceramic inserts are designed for dry machining and can withstand higher temperatures without the need for coolants. Introducing coolant can lead to thermal shock and tool failure.

For roughing operations, cutting speeds tend to be lower to handle greater material removal, typically ranging from 150 to 250 m/min. For finishing operations, higher cutting speeds of up to 1000 m/min can be used, allowing for better surface finishes with minimal tool wear.

Yes, the type of material being machined greatly influences the ideal cutting speed. Harder materials like hardened steel require lower cutting speeds, while softer or more machinable materials like cast iron allow for much higher speeds.

Ceramic inserts are capable of maintaining high cutting speeds even in interrupted cutting conditions, though care must be taken to ensure that the insert geometry and cutting parameters are suitable to avoid chipping or fracture.

If chipping occurs, you may need to reduce the cutting speed, adjust feed rates, or consider using a different tool geometry more suited to the material and operation.

By aligning cutting speed with the specific requirements of your material and application, you can optimize machining performance and get the most out of Halnn’s ceramic inserts.

Our website: https://www.halnncbn.com/

Email: halnntools@halnn-group.com

WhatsApp: +8613271562251

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone