In the field of precision drilling, the carbide tip brazed gun drill stands out as a superior tool for achieving deep, accurate holes in various materials. At Halnn, we pride ourselves on providing high-quality carbide tip brazed gun drills that cater to the needs of multiple industries, including aerospace, automotive, and medical manufacturing. This article explores the specifics of these drills, their advantages, applications, and how Halnn leads the industry with its innovative solutions.

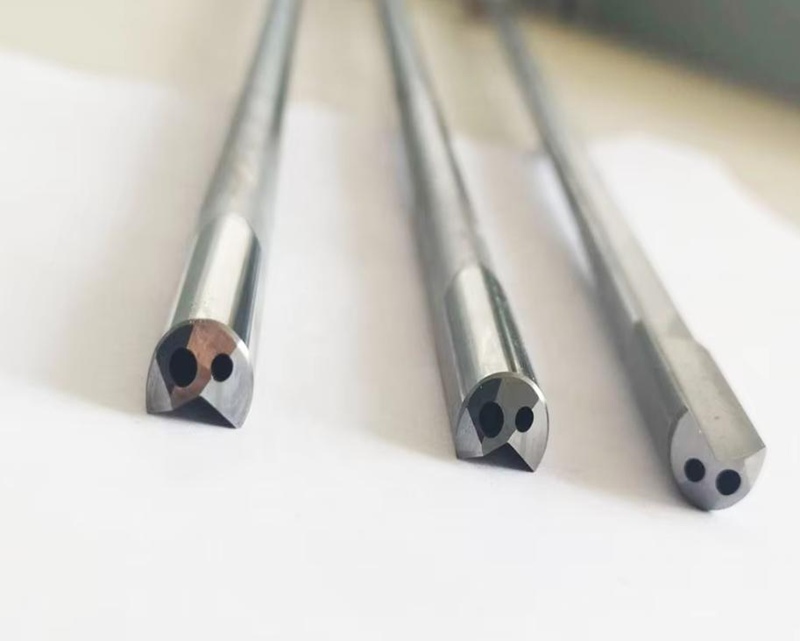

A carbide tip brazed gun drill is a specialized drilling tool designed for creating deep, precise holes with exceptional accuracy. It consists of three primary components:

Carbide Tip: The cutting edge of the drill, made from durable carbide material, which allows for efficient and precise cutting.

Drill Rod: The central shaft that connects the carbide tip to the drill shank, facilitating the transmission of force and rotational motion.

Drill Shank: The end part of the drill that fits into the drilling machine, ensuring stability and proper alignment during operation.

These components are brazed together to form a single, cohesive unit, capable of delivering high performance even under the most demanding conditions. Compared to other types of drills, carbide tip brazed gun drills offer enhanced durability, precision, and efficiency, making them ideal for a variety of applications.

One of the key benefits of using carbide tip brazed gun drills is their ability to produce holes with remarkable precision. The carbide tip ensures a clean and accurate cut, reducing the need for secondary finishing processes. This level of precision is particularly important in industries where exact specifications are crucial, such as aerospace and medical device manufacturing.

Carbide is known for its exceptional hardness and resistance to wear, making it an ideal material for drill tips. This durability allows carbide tip brazed gun drills to maintain their cutting edge for longer periods, reducing downtime and the need for frequent replacements. As a result, they offer a cost-effective solution for long-term drilling projects.

Carbide tip brazed gun drills are designed to operate at high speeds and feed rates, enabling faster drilling and increased productivity. Their efficient cutting action minimizes heat generation and tool wear, allowing them to perform consistently across a wide range of materials, including hard metals and composites.

While the initial investment in carbide tip brazed gun drills may be higher compared to standard drills, their long-term benefits outweigh the costs. The reduced need for tool replacement, combined with improved drilling efficiency, results in significant cost savings over time.

In the aerospace industry, precision and reliability are paramount. Carbide tip brazed gun drills from Halnn are used to manufacture critical components such as engine parts, landing gear, and structural elements. Their ability to create deep, accurate holes in tough materials like titanium and Inconel makes them an essential tool for aerospace manufacturers.

The automotive sector benefits from the use of carbide tip brazed gun drills in the production of engine blocks, transmission components, and suspension systems. These drills enable manufacturers to achieve tight tolerances and high-quality finishes, ensuring the optimal performance of their vehicles.

In the medical device industry, carbide tip brazed gun drills are used to create intricate parts for surgical instruments, implants, and diagnostic equipment. The precision and accuracy of these drills are crucial in ensuring the safety and efficacy of medical devices.

Carbide tip brazed gun drills are also employed in the oil and gas industry for drilling operations in harsh environments. Their durability and resistance to wear make them suitable for creating deep holes in challenging materials, such as rock and hardened steel.

Halnn offers a comprehensive range of carbide tip brazed gun drills designed to meet the diverse needs of our clients. Our product line includes various sizes and configurations, ensuring that we have the right drill for any application. Each drill is meticulously crafted to deliver optimal performance, with specifications tailored to the specific requirements of the industry.

At Halnn, we understand that each project has unique requirements. That's why we offer customization options for our carbide tip brazed gun drills. Whether you need a specific size, length, or coating, our team of experts will work with you to develop a solution that meets your exact needs.

Quality is at the core of everything we do at Halnn. Our carbide tip brazed gun drills undergo rigorous testing and quality control processes to ensure they meet the highest industry standards. We are committed to providing our clients with reliable, high-quality tools that deliver exceptional results.

When selecting a carbide tip brazed gun drill, it's essential to consider the material you will be drilling. Different materials have varying properties, such as hardness and ductility, which can impact the performance of the drill. At Halnn, our experts can guide you in choosing the right drill for your specific application, ensuring optimal results and efficiency.

The size and length of the drill are also critical factors to consider. A drill that is too long or too short can affect the accuracy and stability of the drilling process. Our team at Halnn can help you determine the appropriate size and length based on your project requirements and the specifications of your drilling machine.

Coatings and surface treatments can enhance the performance of carbide tip brazed gun drills by reducing friction, improving wear resistance, and extending the tool's lifespan. At Halnn, we offer a range of coatings and surface treatments to suit different applications and materials.

To ensure the longevity and performance of your carbide tip brazed gun drills, it's essential to conduct regular inspections and cleaning. This helps prevent buildup and wear, allowing the drill to maintain its cutting edge and efficiency.

Proper usage and handling of carbide tip brazed gun drills are crucial to prevent damage and ensure optimal performance. At Halnn, we provide our clients with detailed guidelines and training on how to use and handle our drills safely and effectively.

Over time, even the most durable drills may require re-sharpening or refurbishing. At Halnn, we offer professional re-sharpening and refurbishing services to restore your carbide tip brazed gun drills to their original condition, extending their lifespan and reducing costs.

A: A carbide tip brazed gun drill is a precision tool used for drilling deep, accurate holes in various materials. It features a carbide tip for enhanced durability and cutting efficiency, brazed onto a steel shank. This design combines the benefits of carbide’s hardness and the flexibility of the steel shank.

A: Carbide tip brazed gun drills are suitable for drilling a wide range of materials, including steel, stainless steel, aluminum, titanium, cast iron, and various alloys. The carbide tip allows for efficient drilling through hard and abrasive materials.

A: The key difference lies in the construction of the drill tip. In a carbide tip brazed gun drill, the tip is made of carbide and is brazed onto the drill’s body. This enhances the drill’s hardness and wear resistance, making it more suitable for drilling hard materials compared to other gun drills with steel tips.

A: The benefits include:

High Precision: Achieves accurate, deep holes with minimal deviation.

Durability: Carbide tips are highly resistant to wear and can withstand high temperatures, providing a longer tool life.

Efficiency: Capable of drilling at higher speeds and feeds, reducing overall machining time.

Cost-Effectiveness: Longer tool life and reduced need for tool changes make it a cost-effective solution for high-volume production.

A: Carbide tip brazed gun drills come in various sizes to accommodate different applications. They can range from very small diameters (as small as 1 mm) to larger diameters (up to 50 mm or more), with lengths typically extending up to 1,500 mm or more, depending on the application.

A: Yes, carbide tip brazed gun drills can be customized to meet specific requirements. This includes variations in length, diameter, tip geometry, and coatings to enhance performance for specific applications. Halnn offers customization options to tailor drills to individual customer needs.

A: Proper maintenance includes regular inspections for wear or damage, cleaning to remove debris and buildup, and re-sharpening or re-coating as necessary. Proper storage and handling are also essential to maintain the integrity of the drill.

A: Drilling parameters such as speed, feed rate, and coolant flow depend on the material being drilled and the specific drill being used. Generally, carbide tip brazed gun drills can operate at higher speeds and feed rates than conventional drills. It’s important to follow manufacturer recommendations and adjust parameters based on the specific application.

A: Carbide tip brazed gun drills are compatible with most gun drilling machines, CNC machining centers, and modified lathes designed to handle deep hole drilling. It’s important to ensure that the machine is equipped with the proper setup and capabilities to use these drills effectively.

A: Signs of wear or damage include reduced cutting efficiency, increased vibration, poor hole quality (such as rough surfaces or out-of-tolerance holes), and visible damage to the drill tip or shank. Regular inspections and monitoring of drilling performance can help identify issues early.

A: Various coatings can be applied to carbide tip brazed gun drills to enhance performance, such as TiN (titanium nitride), TiCN (titanium carbonitride), and AlTiN (aluminum titanium nitride). These coatings improve wear resistance, reduce friction, and extend tool life.

A: Yes, carbide tip brazed gun drills can be re-sharpened to restore their cutting edge. This process should be performed by professionals using appropriate equipment to ensure the drill’s geometry and performance are maintained.

Carbide tip brazed gun drills are a valuable tool for achieving precision, efficiency, and durability in drilling applications across various industries. Halnn is committed to providing high-quality carbide tip brazed gun drills that meet the unique needs of our clients. With our extensive product range, customization options, and commitment to quality, we are the ideal partner for all your drilling needs.

Ready to enhance your drilling operations with the best carbide tip brazed gun drills on the market? Contact Halnn today to explore our product range and find the perfect solution for your needs. Visit our website or call our team for a consultation and take the first step towards achieving superior drilling performance.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone