In the world of internal combustion engines, the camshaft plays a pivotal role in ensuring the precise operation of valves. The camshaft's ability to synchronize valve movement is critical for optimal engine performance. Halnn, a leader in precision tooling, offers a comprehensive range of camshaft milling tools designed to meet the demanding requirements of modern engines. This article delves into the intricacies of camshaft milling tools, providing valuable insights and promoting Halnn's expertise in this field.

A camshaft is a rotating object—usually made of metal—that contains pointed cams, which convert rotational motion to reciprocal motion. In internal combustion engines, the camshaft is responsible for opening and closing the intake and exhaust valves. The precise machining of camshafts is essential for enhancing engine efficiency, reducing fuel consumption, and minimizing emissions.

Camshaft milling tools are specialized instruments used to shape the camshaft to exact specifications. Halnn offers a diverse range of camshaft milling tools, including standard and tailor-made solutions, to address various machining requirements.

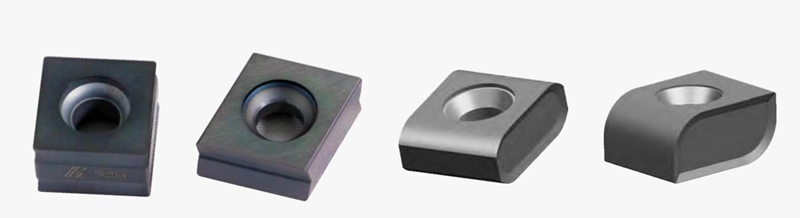

Halnn's camshaft milling inserts are engineered for high-precision milling. These inserts are designed to handle the rigors of camshaft machining, providing consistent performance and longevity. Key features include multi-edge designs that allow for efficient material removal and enhanced surface finish.

Our camshaft milling cutters are designed for the efficient machining of camshaft lobes. These cutters are available in both solid and segmented versions, catering to different production needs. The optimized geometries and high-quality materials used in our cutters ensure durability and precision.

Halnn also offers customized solutions for unique camshaft milling challenges. Our team of experts collaborates with clients to develop engineered solutions that meet specific production requirements, ensuring optimal performance and cost-effectiveness.

The camshaft milling process involves several stages, each requiring specific tools and techniques to achieve the desired precision.

The roughing stage involves the initial shaping of the camshaft. This includes machining the support journal, timing gear journal, and threaded journal outer circle, as well as the cam and eccentric wheel.

During the semi-finishing stage, rough grinding of the cam and eccentric wheel takes place. This step refines the camshaft shape, preparing it for the final finishing stage.

The finishing stage involves fine grinding of the timing pin journal, thrust surface, bearing journals, cam, and eccentric wheel. This step ensures that the camshaft meets the required precision and surface quality.

Halnn’s camshaft milling tools offer several advantages, including:

Improved Precision and Performance: Our tools are designed to achieve high levels of precision, enhancing the overall performance of the camshaft.

Extended Tool Life and Reduced Wear: The use of high-quality materials and advanced designs ensures that our tools have a longer lifespan and reduced wear.

Cost Efficiency: Our tools are optimized for efficient production, helping to lower overall production costs.

Halnn leverages cutting-edge technologies to enhance camshaft milling processes. These innovations include:

Advanced Materials: The use of cubic boron nitride (CBN) grinding wheels improves tool life and precision.

CNC Cam Grinders: These machines use computer programming to achieve high precision, eliminating manual errors.

Electric-Hydraulic Control Systems: These systems provide synchronized movement for high-speed grinding, improving efficiency.

Multiple Grinding Wheels: Using multiple grinding wheels allows for high-speed grinding, enhancing productivity.

Problem: The grinding wheel may not be round after finishing.

Solution: Regular inspection and replacement of the bearing journal turning device and control system.

Problem: Worn machine tools and dies can lead to cam lift tolerance issues.

Solution: Regular inspection, trimming, and timely replacement of the master. Reverse rotation of the workpiece during grinding can improve cam curve accuracy.

Problem: Wear on the machine tool and dies.

Solution: Regular inspection, trimming, and replacement of the master and coupling guide shaft.

Camshaft milling tools are specialized instruments used to shape and finish camshafts in internal combustion engines. These tools include inserts, cutters, and custom solutions designed to achieve high precision and efficiency in camshaft production.

Halnn offers a variety of camshaft milling tools, including camshaft milling inserts, camshaft milling cutters, and tailor-made solutions for specific machining requirements. Our tools are designed to meet the demanding needs of modern engine manufacturing.

Halnn camshaft milling tools provide several benefits, including improved precision, extended tool life, reduced wear, cost-efficiency, and safe production processes. These tools help enhance the overall performance and longevity of camshafts.

Camshaft milling inserts are replaceable components that provide cutting edges for precise material removal, while camshaft milling cutters are complete tools used to shape camshaft lobes. Both are essential for different stages of the milling process.

Choosing the right camshaft milling tool depends on your specific machining requirements, such as the type of camshaft, desired precision, and production volume. Halnn offers expert consultation to help you select the most suitable tool for your application.

Halnn camshaft milling tools are made from high-quality materials, including carbide and cubic boron nitride (CBN). These materials ensure durability, precision, and efficiency in the milling process.

To maintain optimal performance, regularly inspect and clean the tools, replace worn inserts or cutters, and follow the recommended maintenance schedule provided by Halnn. Proper maintenance ensures long tool life and consistent machining quality.

Yes, Halnn offers tailor-made and engineered solutions to meet specific camshaft milling challenges. Our team of experts works closely with clients to develop customized tools that address unique production needs.

The lifespan of a camshaft milling tool depends on various factors, including the material being machined, the operating conditions, and the maintenance practices. Halnn tools are designed for durability and long life under optimal conditions.

Halnn ensures the quality of its camshaft milling tools through rigorous testing, advanced manufacturing techniques, and continuous improvement processes. Our commitment to quality guarantees that our tools meet the highest standards of performance and reliability.

If you encounter issues with your camshaft milling tools, contact Halnn's customer support for assistance. Our team can provide troubleshooting guidance, maintenance tips, and recommendations for replacement parts or tools if needed.

Halnn supports customers by offering expert consultation, technical support, and customized solutions to optimize camshaft milling processes. We aim to help our clients achieve the best possible results with our high-quality tools.

For more information about Halnn camshaft milling tools or to inquire about our products, please visit our website at Halnn Website: https://www.halnncbn.com/ email us at halnntools@halnn-group.com, or contact us via WhatsApp at +8615515925975.

Camshaft milling is a critical process in the manufacturing of high-performance internal combustion engines. Halnn, with its extensive range of camshaft milling tools, offers reliable and efficient solutions to meet the demanding requirements of this process. By leveraging advanced materials and technologies, Halnn ensures that its tools provide superior precision, durability, and cost-efficiency. For more information or to inquire about our products, contact Halnn today.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone