In the precision machining industry, controlling vibrations is essential for achieving high-quality results. Long overhang machining, where tools are extended far from their support, presents unique challenges that can lead to increased vibrations, chatter, and tool deflection. To address these issues, dampened tools have become a critical solution. Halnn is proud to offer a range of high-quality dampened tools specifically designed for long overhang machining.

Dampened tools are specialized machining tools engineered to reduce vibrations during the machining process. These tools incorporate advanced technologies such as tuned mass dampers or viscoelastic materials to absorb and dissipate vibrational energy, ensuring smoother operation and higher precision. By minimizing vibrations, dampened tools enhance the overall performance and longevity of the machining process.

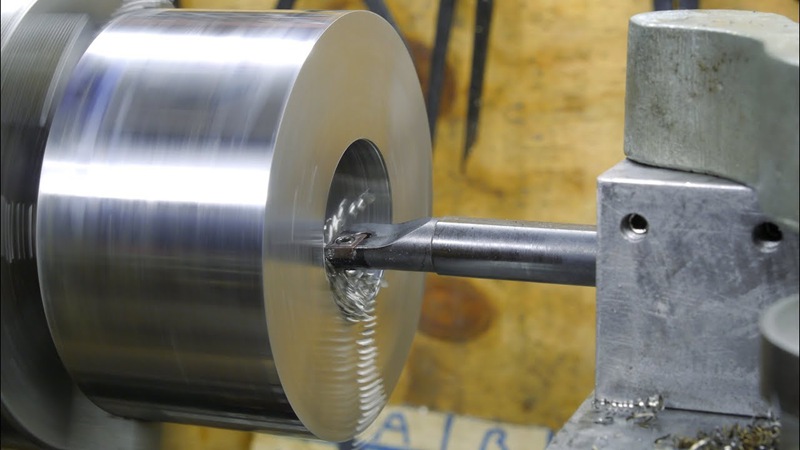

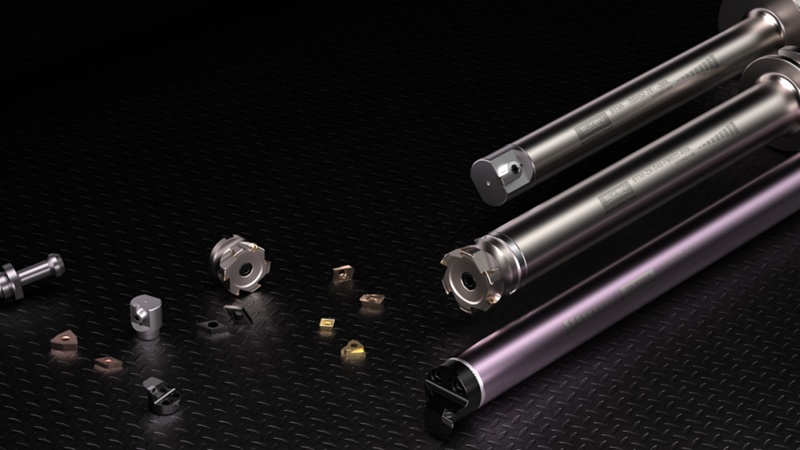

Turning Tools: Designed for precision turning operations, these tools maintain stability even with extended reach, ensuring high accuracy and surface finish.

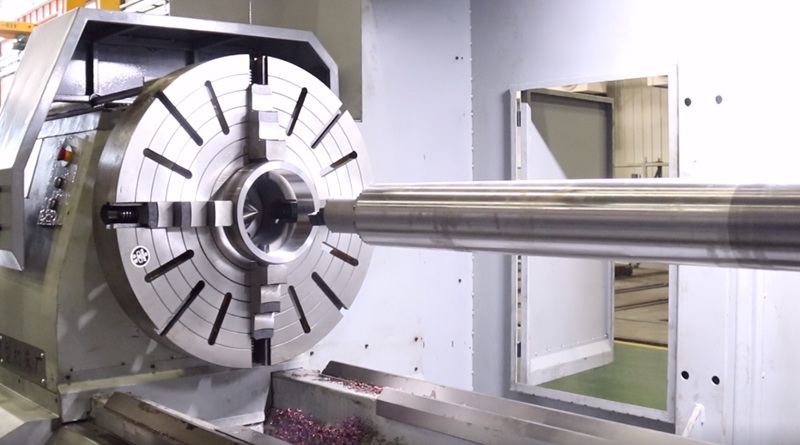

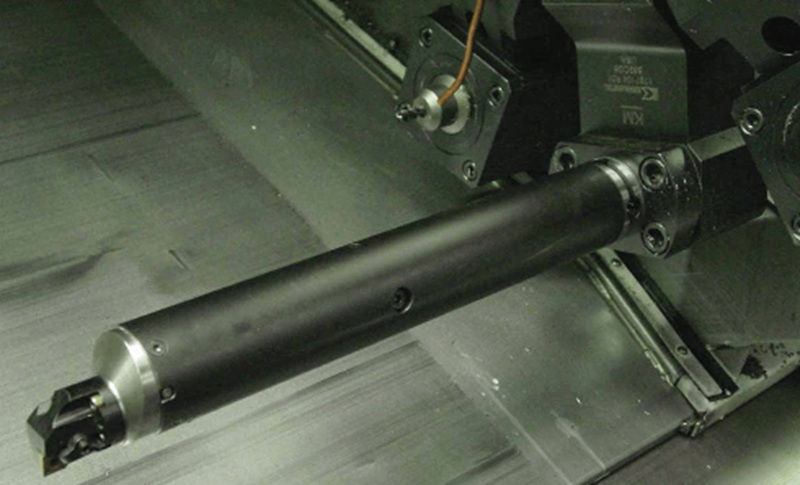

Boring Bars: Ideal for internal machining with long overhangs, dampened boring bars minimize deflection and vibration, crucial for maintaining tight tolerances.

Milling Cutters: Dampened milling cutters provide superior performance in various milling operations, ensuring a high-quality finish and extended tool life.

Long overhang machining involves using tools that extend significantly from their support, leading to increased flexibility and susceptibility to vibrations. These vibrations can cause a host of issues, including:

Poor surface finish

Reduced accuracy

Shortened tool life

Such challenges make it imperative to use specialized tools that can mitigate these problems and ensure optimal machining performance.

Dampened tools effectively counteract the oscillations caused by long overhangs through their built-in vibration-damping mechanisms. These tools work by:

Absorbing and dissipating vibrational energy

Providing stability during machining operations

Enhancing machining accuracy and surface finish

Several case studies have demonstrated the significant improvements achieved with dampened tools. For instance, using dampened boring bars in deep hole drilling operations resulted in reduced tool deflection and improved hole quality. Similarly, dampened turning tools have been shown to enhance surface finish and reduce machining time.

Using dampened tools in long overhang machining offers numerous benefits, including:

Enhanced Machining Accuracy: Reduced vibrations lead to more precise machining, maintaining tight tolerances.

Improved Surface Finish: Smoother operation results in better surface quality, essential for high-precision components.

Extended Tool Life: Minimized vibrations reduce wear and tear on the tools, prolonging their lifespan.

Reduced Machine Downtime: Fewer tool changes and adjustments translate to increased productivity and lower operational costs.

Selecting the appropriate dampened tool for your specific machining needs involves considering several factors:

Material Type: Different materials may require different types of dampened tools.

Machining Conditions: Assessing the specific conditions, such as speed and feed rates, to choose the right tool.

Overhang Length: The extent of the overhang will influence the type of dampened tool required.

Regularly inspect tools for wear and tear

Ensure proper tool setup and alignment

Follow recommended operating parameters

Halnn is a leader in precision machining tools, offering a comprehensive range of dampened tools designed to meet the highest standards. Our products are engineered for durability and performance, backed by customer testimonials and success stories. Our dampened tools are tailored to address the specific challenges of long overhang machining, providing the stability and precision needed for high-quality results.

Dampened tools are essential for overcoming the challenges of long overhang machining. By incorporating these tools into your operations, you can achieve greater precision, improved surface finishes, and extended tool life. Halnn is committed to providing the highest quality dampened tools to meet your machining needs. Contact us today to learn more about our range of dampened tools and how they can enhance your machining processes.

Dampened tools for long overhang machining are specialized machining tools designed to reduce vibrations that occur when the tool extends significantly from its support. These tools incorporate vibration-damping mechanisms to maintain stability, precision, and surface finish during machining operations.

Dampened tools work by incorporating advanced vibration-damping technologies, such as tuned mass dampers or viscoelastic materials, that absorb and dissipate vibrational energy. This helps to minimize oscillations and maintain tool stability, even in long overhang conditions.

Long overhang machining often leads to increased flexibility and susceptibility to vibrations, which can cause poor surface finish, reduced accuracy, and shortened tool life. Dampened tools address these issues by reducing vibrations, ensuring smoother operation and higher precision.

Various types of dampened tools are available, including:

Turning Tools: For precision turning operations.

Boring Bars: Ideal for internal machining with long overhangs.

Milling Cutters: Provide superior performance in milling operations.

By minimizing vibrations, dampened tools reduce the chances of tool deflection and chatter, leading to more precise machining and maintaining tight tolerances.

Yes, dampened tools can extend tool life by reducing the wear and tear caused by vibrations. This leads to fewer tool changes and adjustments, improving overall productivity.

The benefits include:

Enhanced machining accuracy

Improved surface finish

Extended tool life

Reduced machine downtime

Increased productivity

When selecting a dampened tool, consider factors such as:

Material Type: Different materials may require specific types of dampened tools.

Machining Conditions: Assess the specific conditions, such as speed and feed rates.

Overhang Length: The extent of the overhang will influence the type of dampened tool required.

Yes, to ensure optimal performance, regularly inspect tools for wear and tear, ensure proper tool setup and alignment, and follow the recommended operating parameters.

Halnn offers a comprehensive range of high-quality dampened tools designed for long overhang machining. Our products are engineered for durability and performance, ensuring high precision and superior surface finish.

For more information, visit Halnn's website: https://www.halnncbn.com/, or contact us at halnntools@halnn-group.com, WhatsApp: +8615515925975.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone