In the rapidly evolving world of machining, the need for precision, efficiency, and versatility has never been greater. Enter the CAPTO tool system—a revolutionary approach to tool holding that is transforming the industry. At Halnn, we pride ourselves on offering top-tier CAPTO tool systems that meet the highest standards of performance and reliability. This article delves into the intricacies of the CAPTO tool system, highlighting its features, benefits, and applications, while showcasing why Halnn's offerings stand out in the market.

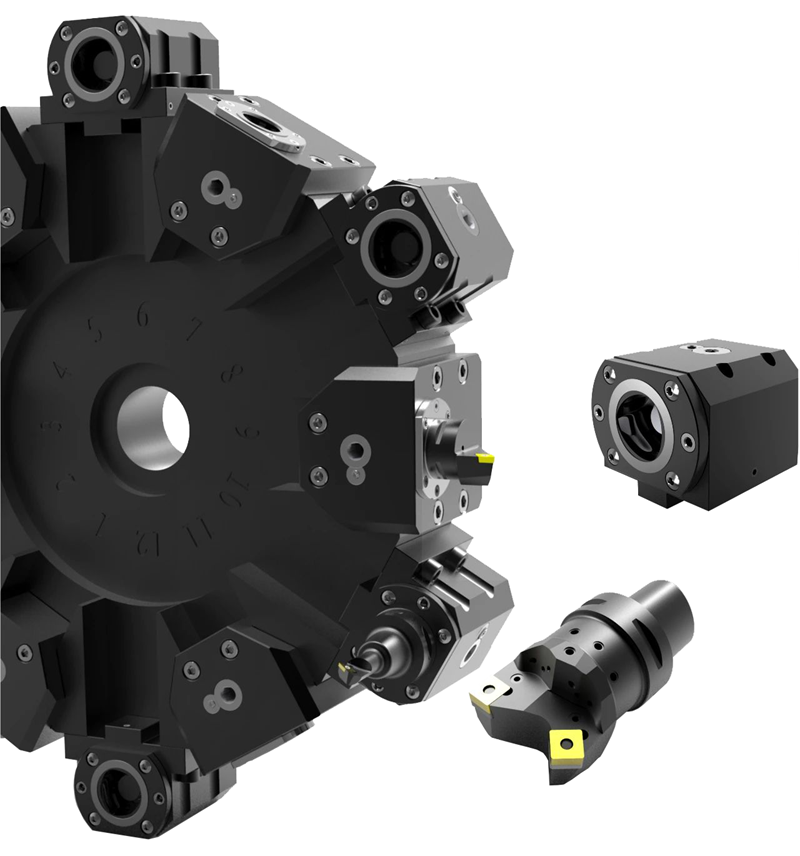

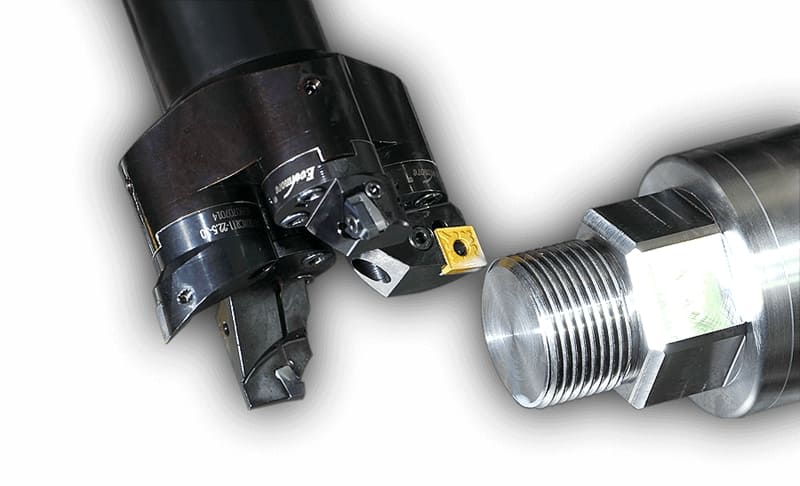

The CAPTO tool system is a modular tool holding system designed to optimize machining efficiency and accuracy. Developed with the aim of reducing tool change times and enhancing rigidity, CAPTO has become a staple in various high-precision industries. It combines a polygonal shank with a self-centering taper, ensuring superior stability and repeatability. The system's design allows for quick tool changes without sacrificing precision, making it ideal for modern manufacturing environments.

Polygonal Shank Coupling (PSC): The CAPTO system's polygonal shank provides high torque transmission and minimal radial runout.

Quick Change Capability: Reduces downtime significantly, enhancing overall productivity.

Versatility: Compatible with a wide range of machining operations and machine tools.

High Rigidity: Ensures stable and accurate machining, even under heavy loads.

The CAPTO tool system is known for its robust technical specifications. The tool holders are typically made from high-strength steel, ensuring durability and longevity. The self-centering taper and polygonal shank design provide a high level of precision and stability. CAPTO tool holders come in various sizes and configurations, making them suitable for different types of machining operations.

The polygonal shank and self-centering taper ensure that the tool holder remains stable during machining operations. This results in improved surface finish and dimensional accuracy of the workpiece.

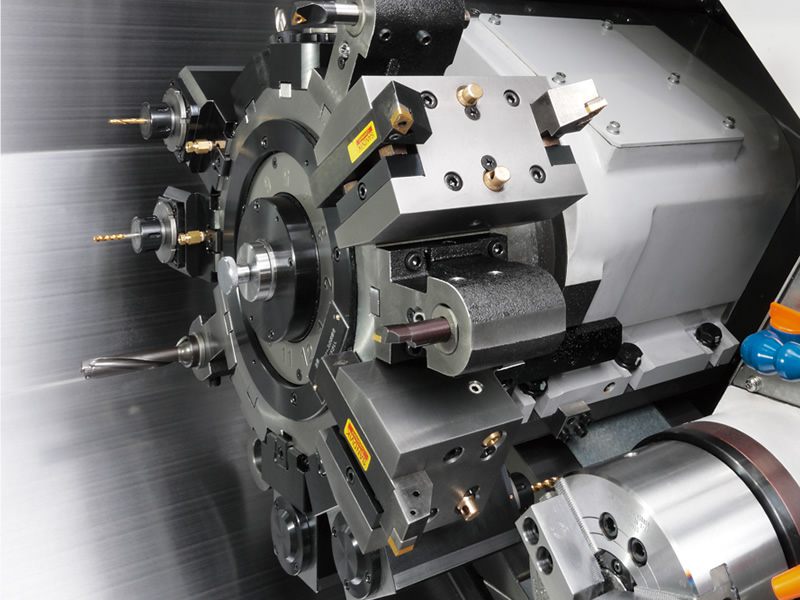

The modular design of the CAPTO tool system allows for rapid tool changes, minimizing machine downtime. This quick-change capability is particularly beneficial in high-production environments where time is critical.

The high repeatability of the CAPTO system ensures that each tool change maintains the same level of precision. This consistency is crucial for maintaining quality in high-precision machining applications.

The CAPTO tool system's versatility makes it suitable for a wide range of applications, from turning and milling to drilling and boring. Its compatibility with different machine tools further enhances its adaptability.

In the automotive industry, precision and efficiency are paramount. The CAPTO tool system is used extensively for machining engine components, transmission parts, and other critical components, ensuring high quality and reliability.

Aerospace components demand the highest levels of precision and consistency. The CAPTO tool system's stability and accuracy make it ideal for machining complex parts used in aircraft and spacecraft.

The medical device industry requires exacting standards of precision and cleanliness. The CAPTO tool system's repeatability and quick-change capability ensure that these standards are met, even in high-volume production environments.

From small machine shops to large manufacturing facilities, the CAPTO tool system provides the versatility and reliability needed for a variety of machining tasks. Its adaptability makes it a valuable asset in any machining operation.

At Halnn, we offer a comprehensive range of CAPTO tool systems designed to meet the diverse needs of our clients. Our products are engineered to provide maximum performance and reliability, backed by years of research and development.

Superior Material Quality: We use high-strength steel and advanced manufacturing processes to ensure the durability and performance of our CAPTO tool holders.

Innovative Design: Our tool holders are designed with the latest technological advancements to provide enhanced rigidity and precision.

Customer Testimonials: Our clients have consistently reported improved productivity and quality in their machining operations after switching to Halnn's CAPTO tool system.

When selecting a CAPTO tool system, consider factors such as the type of machining operations, machine tool compatibility, and specific requirements of your application. Halnn offers a variety of sizes and configurations to ensure you find the perfect match for your needs.

Regular Maintenance: Keep the tool holders clean and well-lubricated to maintain performance.

Proper Installation: Ensure that the tool holders are installed correctly to prevent runout and other issues.

Monitor Tool Wear: Regularly inspect the tool holders for signs of wear and replace them as needed to maintain precision.

Maintaining your CAPTO tool system is essential for ensuring long-term performance and reliability. Follow these best practices to keep your tool holders in top condition:

Clean Regularly: Remove any debris or coolant residue after each use.

Lubricate: Apply appropriate lubrication to prevent rust and ensure smooth operation.

Inspect for Wear: Regularly check for signs of wear or damage and replace components as necessary.

A1: The CAPTO tool system is a modular tool holding system designed to enhance machining precision, efficiency, and versatility. It features a unique polygonal shank and self-centering taper that ensures high rigidity and quick tool changes.

A2: The CAPTO tool system offers several benefits including quick tool changes, improved precision and accuracy, high rigidity and stability, and versatility across various machining applications.

A3: By allowing quick tool changes and maintaining high rigidity and precision, the CAPTO tool system reduces downtime and ensures consistent quality, thereby enhancing overall machining efficiency.

A4: The CAPTO tool system is widely used in the automotive, aerospace, medical device manufacturing, and general machining industries due to its precision and versatility.

A5: The CAPTO tool system features a polygonal shank and self-centering taper design, which provides high torque transmission, minimal radial runout, and superior stability during machining operations.

A6: Yes, the CAPTO tool system is compatible with a wide range of machine tools, making it a versatile choice for various machining applications.

A7: Regular maintenance is essential for optimal performance. This includes cleaning the tool holders, lubricating them to prevent rust, and inspecting for wear to ensure longevity and reliability.

A8: Halnn's CAPTO tool system is known for its superior material quality, innovative design, and proven performance. Our tool holders are engineered for maximum durability and precision, backed by extensive research and development.

A9: Yes, the CAPTO tool system is available in various sizes and configurations to meet the specific needs of different machining operations and applications.

A10: The high rigidity and precision of the CAPTO tool system ensure stable and accurate machining, resulting in improved surface finish and dimensional accuracy of the workpieces.

A11: Yes, the CAPTO tool system is designed to maintain stability and accuracy even under heavy machining loads, making it suitable for demanding applications.

A12: The quick-change capability significantly reduces machine downtime during tool changes, enhancing productivity and efficiency in high-production environments.

The CAPTO tool system represents a significant advancement in machining technology, offering unparalleled precision, efficiency, and versatility. At Halnn, we are committed to providing top-quality CAPTO tool systems that meet the highest standards of performance and reliability. Whether you're in the automotive, aerospace, medical device, or general manufacturing industry, our CAPTO tool systems can help you achieve your machining goals with ease and confidence.

For more information or to purchase Halnn's CAPTO tool system, contact us today. Our team of experts is ready to assist you in selecting the right tool system for your needs.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone