In the world of precision machining, even the slightest vibrations can lead to significant imperfections on the workpiece surface. This can increase surface roughness, compromise dimensional accuracy, and even shorten tool life. Effective vibration control is crucial for maintaining high machining standards, and one of the most efficient solutions is the use of anti-vibration damping tool bars. In this article, we will explore the importance, functionality, and applications of anti-vibration damping tool bars, with a special focus on Halnn's innovative solutions.

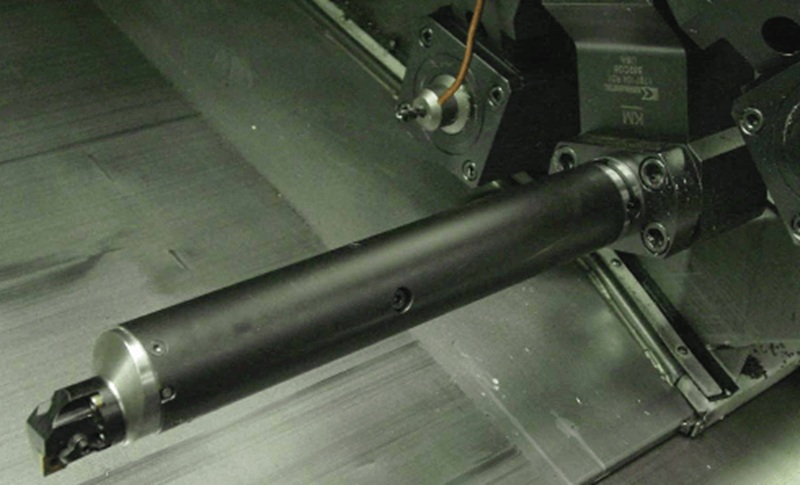

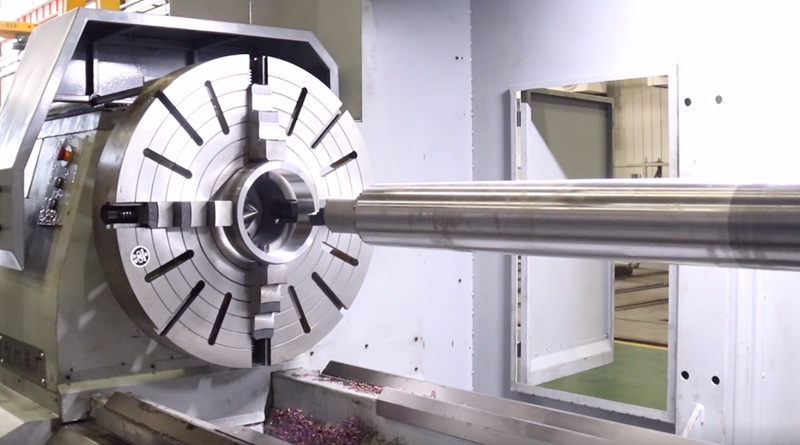

Anti-vibration damping tool bars are specialized tools designed to minimize the vibrations that occur during machining processes. These bars are constructed using advanced materials and engineering techniques that absorb and dissipate vibrational energy, ensuring smoother and more precise machining operations. Unlike standard tool bars, anti-vibration damping tool bars are specifically engineered to counteract the forces that cause tool chatter and instability.

Vibrations in machining can lead to several adverse effects, including:

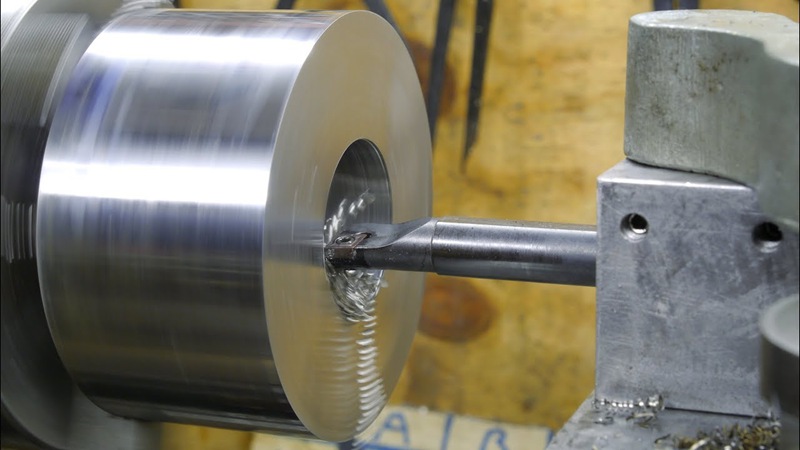

Poor Surface Finish: Vibrations cause irregularities on the machined surface, increasing roughness.

Reduced Dimensional Accuracy: Excessive vibrations can cause deviations from the desired dimensions.

Shortened Tool Life: Vibrations increase tool wear and can lead to premature tool failure.

Decreased Productivity: Unstable machining conditions can slow down operations and increase the likelihood of errors.

Improved Surface Finish: These tool bars significantly reduce vibrations, resulting in a smoother surface finish.

Enhanced Dimensional Accuracy: By stabilizing the cutting process, they ensure precise adherence to specified dimensions.

Extended Tool Life: Reducing vibrations minimizes tool wear, thereby extending the tool’s lifespan.

Increased Productivity: Stable machining conditions enable higher cutting speeds and feeds, improving overall productivity.

Anti-vibration damping tool bars incorporate advanced damping mechanisms that absorb and neutralize vibrational energy. These mechanisms typically involve the use of materials and designs that counteract the forces causing vibration. The damping materials, often viscoelastic or composite materials, are strategically placed within the tool bar to maximize their effectiveness. The design features, such as mass distribution and stiffness, are optimized to enhance vibration absorption.

Anti-vibration damping tool bars are invaluable in industries where precision and surface quality are paramount, including:

Aerospace: Precision components and complex geometries require high stability during machining.

Automotive: Critical parts like engine blocks and transmission housings benefit from reduced vibrations.

Heavy Machinery: Large, intricate parts require stable machining processes to ensure quality and accuracy.

Boring: Achieving tight tolerances and smooth finishes in deep boreholes.

Turning: Stabilizing the turning process to improve surface quality and dimensional accuracy.

Milling: Enhancing the performance of face milling and end milling operations.

When selecting an anti-vibration damping tool bar, consider the following factors:

Material Compatibility: Ensure the tool bar material is suitable for the workpiece material.

Size and Length: Match the tool bar size and length to the specific machining operation.

Damping Efficiency: Choose a tool bar with proven damping capabilities for optimal performance.

Consult Manufacturer Specifications: Review the technical specifications provided by the manufacturer.

Evaluate Application Needs: Consider the specific requirements of your machining operations.

Seek Expert Advice: Consult with tool manufacturers or industry experts for recommendations.

Proper maintenance is essential to ensure the longevity and performance of anti-vibration damping tool bars:

Regular Inspection: Check for signs of wear and damage regularly.

Cleaning: Keep the tool bars clean to prevent the buildup of debris and contaminants.

Proper Storage: Store the tool bars in a controlled environment to prevent damage.

Increased Vibrations: If vibrations increase, it may indicate wear or damage.

Surface Finish Deterioration: A decline in surface finish quality can signal the need for replacement.

Visible Damage: Inspect for cracks, chips, or other visible signs of damage.

Halnn, a leader in the machining tool industry, offers cutting-edge anti-vibration damping tool bars designed to meet the highest standards of precision and efficiency. Here’s why Halnn stands out:

Expertise and Innovation: With years of experience and a commitment to innovation, Halnn delivers top-quality solutions tailored to industry needs.

Comprehensive Product Range: Halnn provides a wide range of anti-vibration damping tool bars suitable for various applications.

Customer Satisfaction: Halnn’s dedication to customer satisfaction is reflected in the positive feedback and success stories from clients worldwide.

A1: An anti-vibration damping tool bar is a specialized machining tool designed to minimize vibrations during machining processes. It incorporates advanced damping materials and designs to absorb and dissipate vibrational energy, ensuring smoother and more precise operations.

A2: These tool bars work by using materials and internal structures that counteract the forces causing vibration. The damping materials, often viscoelastic or composite, absorb the vibrational energy, while the optimized design features help in stabilizing the cutting process.

A3: The benefits include improved surface finish, enhanced dimensional accuracy, extended tool life, and increased productivity. By reducing vibrations, these tool bars ensure stable machining conditions, leading to higher quality and efficiency.

A4: Anti-vibration damping tool bars are commonly used in aerospace, automotive, heavy machinery, and precision manufacturing industries. These sectors require high standards of machining precision and surface quality.

A5: Yes, they can be used for a variety of machining operations, including boring, turning, and milling. However, it's important to choose the right tool bar specific to the operation and material being machined.

A6: Consider factors such as material compatibility, size and length of the tool bar, and its damping efficiency. Review the technical specifications provided by the manufacturer and consult with experts if needed.

A7: Regular inspection for wear and damage, keeping the tool bars clean, and proper storage are essential maintenance practices. Additionally, monitoring for increased vibrations or deteriorating surface finish can indicate when replacement is needed.

A8: Increased vibrations, poor surface finish quality, and visible damage such as cracks or chips are common signs that a tool bar needs replacement. Regular maintenance and monitoring can help detect these issues early.

A9: Halnn offers cutting-edge anti-vibration damping tool bars designed to meet high precision and efficiency standards. With a commitment to innovation, comprehensive product range, and a focus on customer satisfaction, Halnn stands out as a trusted partner in the machining tool industry.

A10: For more information, you can contact Halnn directly or visit their website. Halnn provides detailed product information, technical support, and customer service to help you choose the best solution for your machining needs.

Anti-vibration damping tool bars are essential for achieving high precision, superior surface finish, and enhanced productivity in machining operations. Halnn’s expertise and innovative solutions make them a trusted partner for industries seeking to optimize their machining processes. By choosing Halnn’s anti-vibration damping tool bars, you can significantly improve your machining outcomes, reduce costs, and enhance overall efficiency.

For more information about Halnn’s anti-vibration damping tool bars, contact us today or visit our website. Let Halnn help you achieve unparalleled machining precision and performance.

Our website: https://www.halnncbn.com/

Email: halnntools@halnn-group.com

WhatsApp: +8615515925975

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone