In the realm of precision machining, vibration-damped boring bars have emerged as a revolutionary tool, addressing the common issue of chatter and vibration during the cutting process. This article delves into the specifics of vibration-damped boring bars, with a special focus on Halnn cutting-edge solutions. Whether you're dealing with deep hole boring or complex internal turning, understanding the benefits and applications of these advanced tools can significantly enhance your machining outcomes.

A vibration-damped boring bar, also known as a dampened boring bar or damped machining tool, is a specialized cutting tool designed to minimize vibrations during the boring process. These vibrations, often referred to as chatter, can lead to poor surface finish, reduced tool life, and inaccuracies in the machined part. Vibration-damped boring bars incorporate advanced damping mechanisms that absorb and dissipate these unwanted oscillations, ensuring a smoother, more stable cutting process.

The core of a vibration-damped boring bar is its internal damping system. This system typically consists of tuned mass dampers or other vibration-absorbing materials strategically placed within the bar. These components counteract the natural frequencies generated during cutting, effectively reducing the amplitude of vibrations.

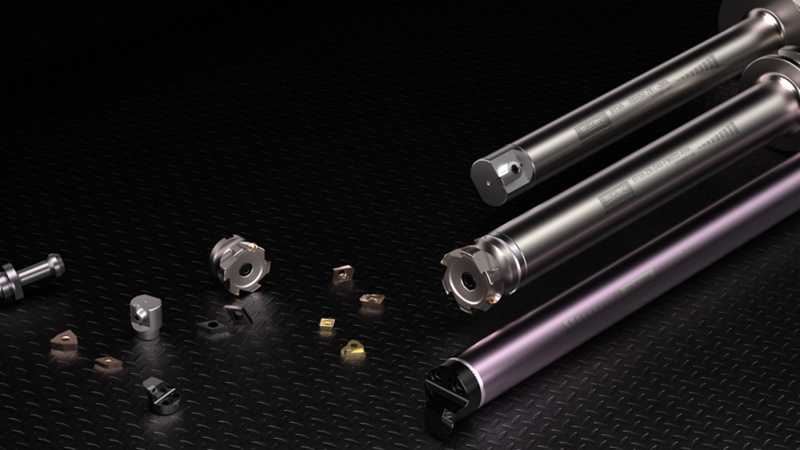

Halnn vibration-damped boring bars are crafted from high-strength alloy steel and advanced composites, which not only provide the necessary rigidity but also contribute to the overall damping effect. This combination of materials ensures that the boring bar can withstand the demanding conditions of deep hole and internal machining while maintaining high precision.

One of the most immediate benefits of using a vibration-damped boring bar is the improved surface finish of the machined part. By minimizing vibrations, these tools produce smoother surfaces with fewer defects, which is crucial in high-precision applications such as aerospace and automotive components.

Vibrations can cause premature wear and tear on cutting tools. Halnn vibration-damped boring bars extend tool life by maintaining stable cutting conditions, reducing the need for frequent tool changes and downtime.

Traditional boring bars struggle with maintaining accuracy at greater depth-to-diameter ratios. Vibration-damped boring bars excel in this aspect, allowing for deeper cuts without sacrificing precision, making them ideal for deep hole boring and other challenging applications.

Halnn offers a range of vibration-damped boring bars that can be customized to suit specific machining needs. Whether you require a solution for internal turning or complex boring operations, Halnn tools can be tailored to meet your exact requirements.

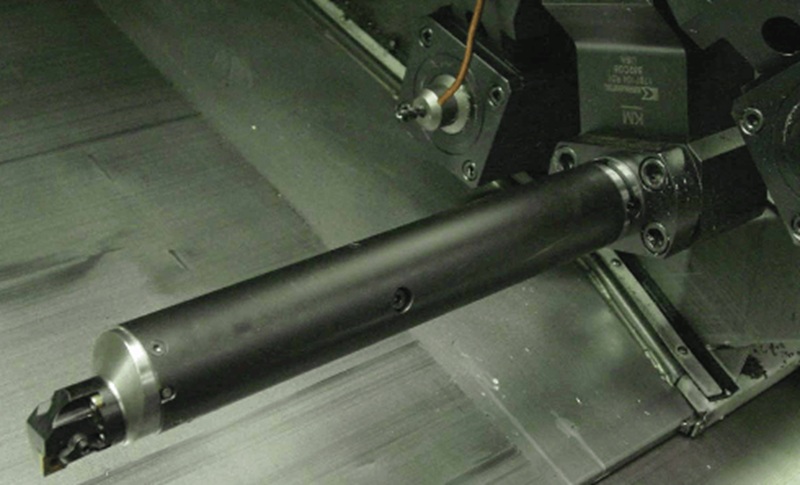

Deep hole boring is notoriously challenging due to the high risk of vibrations and chatter. Halnn vibration-damped boring bars are specifically designed to handle these conditions, providing stable, accurate cutting even at significant depths.

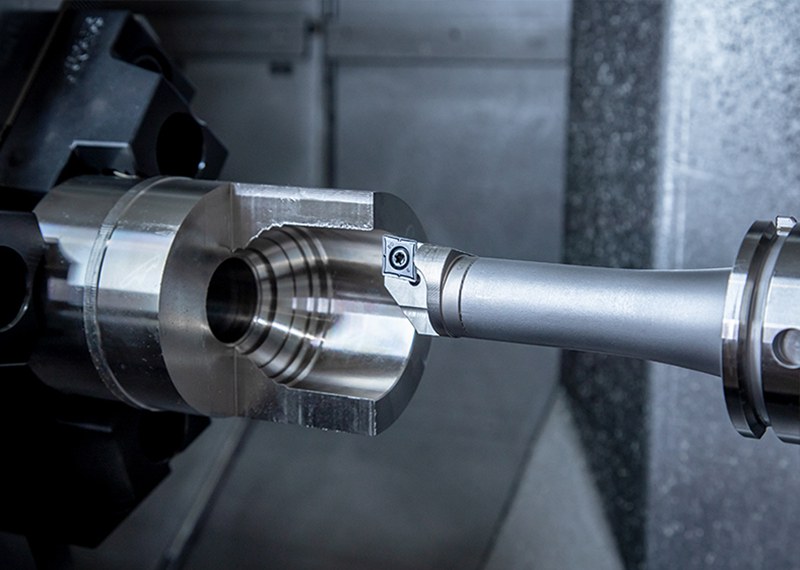

In internal turning operations, maintaining tool stability is critical. Vibration-damped boring bars from Halnn ensure consistent performance, allowing for precise machining of internal features without the risk of chatter-induced errors.

For heavy-duty machining tasks that involve large, high-strength materials, the robust construction and advanced damping capabilities of Halnn boring bars make them an indispensable tool in achieving high-quality results.

Component: Aerospace Engine Housing

Material: High-strength alloy steel, HRC48-54

Machine: Heavy-duty horizontal lathe

Tool Used: Halnn VH80 C130x2475VE.R-21090 Vibration-damped Boring Bar

Results: The machining process was stable, with no audible vibrations or chatter. The surface finish met the required Ra3.2 standard, and the tool life was significantly extended. The customer reported a marked improvement in machining efficiency and part accuracy.

A vibration-damped boring bar is a specialized cutting tool designed to minimize vibrations during the boring process. These tools incorporate advanced damping mechanisms to absorb and dissipate unwanted oscillations, ensuring a smoother and more stable cutting operation.

A vibration-damped boring bar works by using internal damping systems, such as tuned mass dampers or vibration-absorbing materials. These components counteract the natural frequencies generated during cutting, reducing the amplitude of vibrations and resulting in a more stable machining process.

Improved Surface Finish: Minimizes vibrations, leading to smoother surfaces with fewer defects.

Increased Tool Life: Reduces premature wear and tear on cutting tools, extending their lifespan.

Greater Depth-to-Diameter Ratios: Allows for deeper cuts without sacrificing precision.

Enhanced Machining Stability: Provides stable cutting conditions even in challenging applications.

Vibration-damped boring bars are typically made from high-strength alloy steel and advanced composites. These materials provide the necessary rigidity and contribute to the overall damping effect, ensuring the tool can withstand demanding machining conditions.

Yes, Halnn offers a range of vibration-damped boring bars that can be customized to suit specific machining needs. Whether you require a solution for internal turning or complex boring operations, Halnn tools can be tailored to meet your exact requirements.

Deep Hole Boring: Ideal for stable, accurate cutting at significant depths.

Internal Turning: Ensures consistent performance in internal machining operations.

Heavy-duty Machining: Suitable for machining large, high-strength materials.

By minimizing vibrations, vibration-damped boring bars reduce the stress and wear on cutting tools. This leads to longer tool life and reduces the need for frequent tool changes, enhancing overall productivity and efficiency.

Cutting parameters can vary based on the material and specific application. For example, in a heavy-duty machining task with Halnn VH80 C130x2475VE.R-21090 Vibration-damped Boring Bar, parameters might include a cutting speed (vc) of 60 m/min, feed rate (fn) of 0.2 mm/r, and cutting depth (ap) of 0.2 mm.

Choosing the right vibration-damped boring bar involves considering factors such as the material being machined, the required depth-to-diameter ratio, and the specific machining operation (e.g., deep hole boring or internal turning). Consulting with Halnn sales team can help you select the optimal tool for your needs.

Halnn vibration-damped boring bars are engineered with advanced damping technologies and high-quality materials, ensuring superior performance and reliability. Our commitment to innovation and customer satisfaction makes Halnn the ideal choice for precision machining solutions.

Halnn vibration-damped boring bars can achieve a maximum length-to-diameter ratio of up to 18 times, providing excellent stability and precision even in deep hole boring applications.

Vibration-damped boring bars represent a significant advancement in precision machining technology. Halnn commitment to innovation and quality ensures that their tools deliver superior performance in even the most challenging applications. By incorporating Halnn vibration-damped boring bars into your machining processes, you can achieve higher precision, better surface finishes, and increased tool life, ultimately leading to greater productivity and cost savings.

For more information on how Halnn vibration-damped boring bars can benefit your machining operations, contact our sales team today. Experience the Halnn difference in precision and performance.

Our website: https://www.halnncbn.com/

Email: halnntools@halnn-group.com

WhatsApp: +8615515925975

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone