In the dynamic world of precision machining, having the right tools can significantly impact efficiency and product quality. The Capto cutting tool holder stands out as a versatile and reliable solution for various machining operations. This comprehensive guide will delve into the features, benefits, and applications of Capto cutting tool holders, emphasizing why Halnn's offerings are the best in the market.

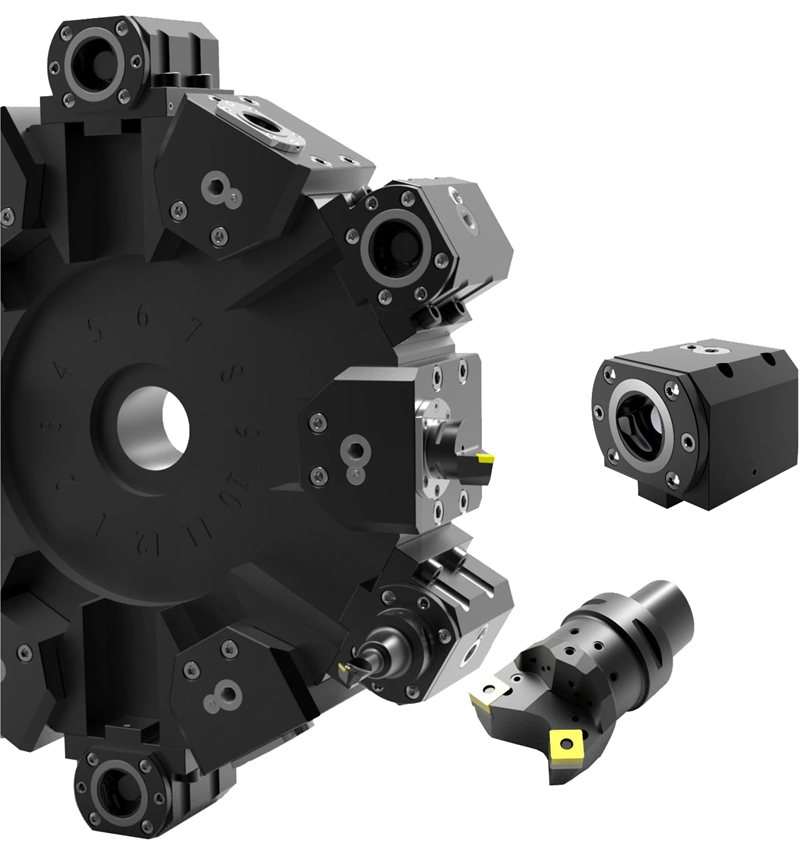

A Capto cutting tool holder is a modular tool system designed to enhance the performance of machining operations. Known for its high rigidity and precision, the Capto system facilitates quick tool changes, minimizes downtime, and ensures consistent quality in machining tasks. Halnn, a leading name in the industry, manufactures top-of-the-line Capto tool holders tailored to meet the rigorous demands of modern machining.

Capto tool holders are renowned for their robust design, which significantly reduces tool deflection and vibration. This stability ensures precise and high-quality machining, even under challenging conditions.

The exceptional clamping force and stability of Capto holders enhance the accuracy of machining operations. This precision is crucial for industries requiring tight tolerances and superior surface finishes.

The modular design of Capto tool holders allows for rapid tool changes, minimizing downtime and increasing productivity. This feature is particularly beneficial in high-mix, low-volume production environments.

Capto tool holders are compatible with a wide range of machining operations, from turning and milling to drilling. This versatility makes them an invaluable asset in any machine shop.

Capto tool holders feature a polygonal coupling interface, providing a secure and precise connection between the tool holder and the machine spindle. This design minimizes runout and ensures consistent performance. The quick-change capability of Capto holders allows for seamless transitions between different tools, enhancing overall efficiency.

Halnn offers a diverse range of Capto cutting tool holders to cater to various machining needs. These include:

CAPTO Turning Tool Holders: Ideal for turning operations, these holders provide exceptional stability and precision.

CAPTO Milling Tool Holders: Designed for milling applications, ensuring high accuracy and efficient material removal.

CAPTO Drilling Tool Holders: Suitable for drilling tasks, offering reliable performance and ease of use.

Each type is available in various sizes and configurations to meet specific requirements. Halnn also offers customization options to tailor the tool holders to unique machining challenges.

Capto tool holders are widely used across multiple industries due to their versatility and reliability. Common applications include:

Aerospace: Precision machining of complex components with tight tolerances.

Automotive: Efficient production of high-quality parts.

Energy: Machining of robust materials for power generation equipment.

General Engineering: Versatile applications in various machining tasks.

A notable example of Halnn's expertise is the successful implementation of Capto tool holders in an aerospace company. The client reported a significant reduction in setup times and enhanced machining precision, leading to improved overall productivity and product quality.

Selecting the appropriate Capto tool holder involves considering several factors:

Material: The type of material being machined impacts the choice of tool holder.

Machining Process: Different processes require specific tool holder designs.

Machine Compatibility: Ensuring the tool holder is compatible with the existing machine setup.

Halnn's experts are available to provide personalized recommendations based on your unique needs.

Proper maintenance is essential for maximizing the lifespan and performance of Capto tool holders. Best practices include:

Regular Cleaning: Remove debris and contaminants to prevent wear and tear.

Lubrication: Apply appropriate lubricants to moving parts to reduce friction.

Inspection: Periodically check for signs of damage or wear and replace parts as needed.

Halnn is dedicated to delivering the highest quality products, utilizing advanced manufacturing techniques and rigorous quality control processes.

Halnn’s Capto tool holders have received positive feedback from customers across various industries, highlighting their reliability and performance.

Halnn’s Capto tool holders offer superior performance compared to competitors, backed by exceptional customer support and expertise.

A Capto cutting tool holder is a modular tool holding system known for its versatility, rigidity, and precision. It is used in various machining operations, including turning, milling, and drilling.

The benefits include:

Enhanced rigidity and stability

Improved machining accuracy

Quick and easy tool changes

Versatility in different machining applications

The Capto system allows for rapid tool changes, minimizing downtime. Its high stability reduces tool deflection and vibration, leading to consistent and high-quality machining.

Capto tool holders are designed to be compatible with most modern machining centers and lathes. However, it's essential to check for specific compatibility with your machine setup.

Halnn’s Capto tool holders are known for their superior quality, precision, and durability. Halnn employs advanced manufacturing techniques and rigorous quality control to ensure top performance.

Yes, Halnn offers various types of Capto cutting tool holders, including those for turning, milling, and drilling. Each type is available in multiple sizes and configurations to meet specific machining needs.

Regular maintenance involves:

Cleaning to remove debris and contaminants

Lubricating moving parts to reduce friction

Inspecting for signs of wear or damage and replacing parts as needed

Capto cutting tool holders are suitable for machining a wide range of materials, including metals like steel, aluminum, and titanium, as well as composites and plastics.

Consider factors such as the material being machined, the specific machining process, and machine compatibility. Halnn’s experts can provide personalized recommendations based on your unique requirements.

Yes, Halnn offers customization options to tailor Capto cutting tool holders to unique machining challenges, ensuring optimal performance and efficiency.

Capto tool holders are widely used in industries such as aerospace, automotive, energy, and general engineering due to their precision and versatility.

You can purchase Halnn’s Capto cutting tool holders directly from Halnn’s website or through authorized distributors. Contact Halnn for more details and assistance.

Capto tool holders offer a unique combination of modularity, high rigidity, and quick-change capabilities, making them more versatile and efficient compared to many traditional tool holding systems.

While the initial investment might be higher, the efficiency, reduced downtime, and improved machining quality provided by Capto cutting tool holders make them a cost-effective choice in the long run.

Halnn offers comprehensive support and technical assistance for all their products. You can contact Halnn’s customer service or technical support team for help.

Capto cutting tool holders are an essential component for achieving high precision and efficiency in modern machining. With Halnn’s expertise and commitment to quality, you can trust our Capto tool holders to meet your most demanding machining needs. Contact Halnn today to learn more about our products and how we can help optimize your machining operations.

Our website: https://www.halnncbn.com/

Email: halnntools@halnn-group.com

WhatsApp: +8615515925975

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone