In the world of machining, precision and efficiency are paramount. The right tool holder plays a crucial role in achieving these objectives. The PSC (Polygon Shank Coupling) tool holder, with its unique design and robust features, has become the go-to solution for many machining professionals. Halnn, a renowned name in the industry, offers top-of-the-line PSC tool holders that set the benchmark for quality and performance.

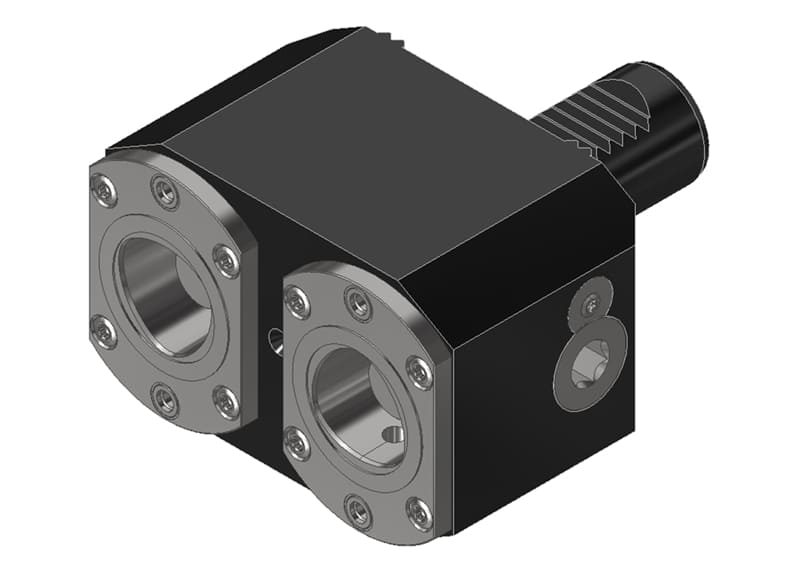

A PSC tool holder, or Polygon Shank Coupling tool holder, is an advanced tool holding system designed for high precision and stability. It features a polygonal taper interface and flange contact, ensuring a strong, rigid connection between the tool and the machine, minimizing deflection and vibration during machining operations.

The polygonal taper interface provides exceptional rigidity, reducing tool deflection and vibration, leading to superior surface finishes and enhanced machining accuracy.

PSC tool holders allow for rapid tool changes, significantly reducing downtime and increasing productivity. This quick-change feature ensures seamless operation transitions without compromising precision.

Consistent and repeatable tool positioning with PSC tool holders ensures high precision and accuracy in every machining operation, crucial for industries like aerospace, automotive, and medical device manufacturing.

The stability and precision offered by PSC tool holders minimize wear and tear, extending the tool life and reducing the frequency of replacements.

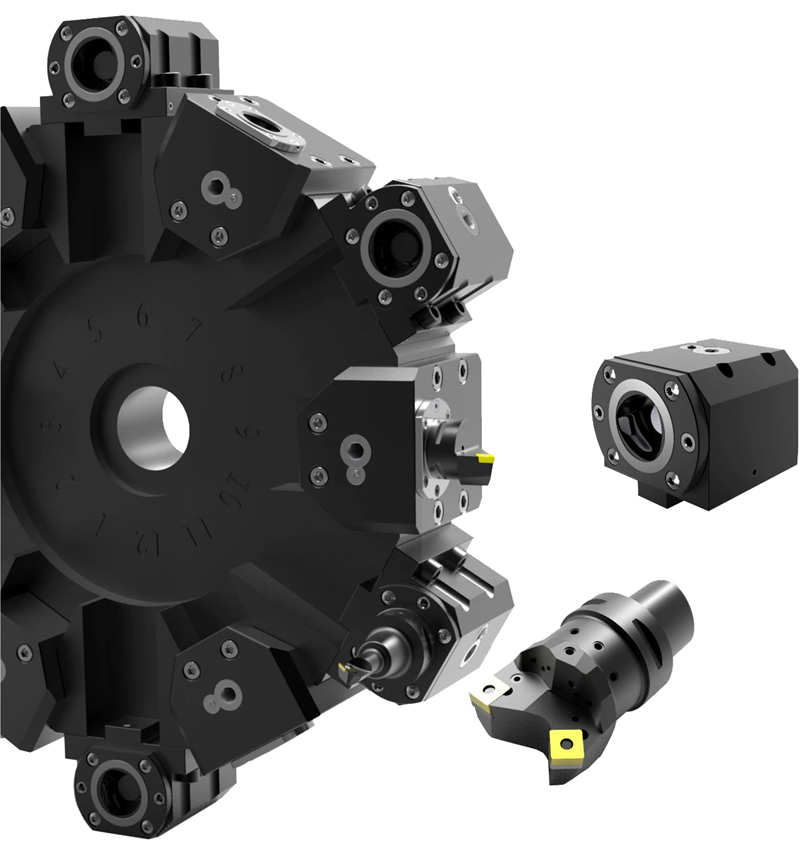

Halnn offers a comprehensive range of PSC tool holders, including turning, milling, boring, and drilling tool holders, making them suitable for a wide array of machining applications.

Designed for high-precision turning operations, these tool holders provide exceptional stability and accuracy.

Ideal for various milling operations, including slot milling, face milling, and contour milling.

Engineered for precision boring operations, ensuring consistent and accurate results.

Perfect for high-precision drilling tasks, providing excellent tool stability and longevity.

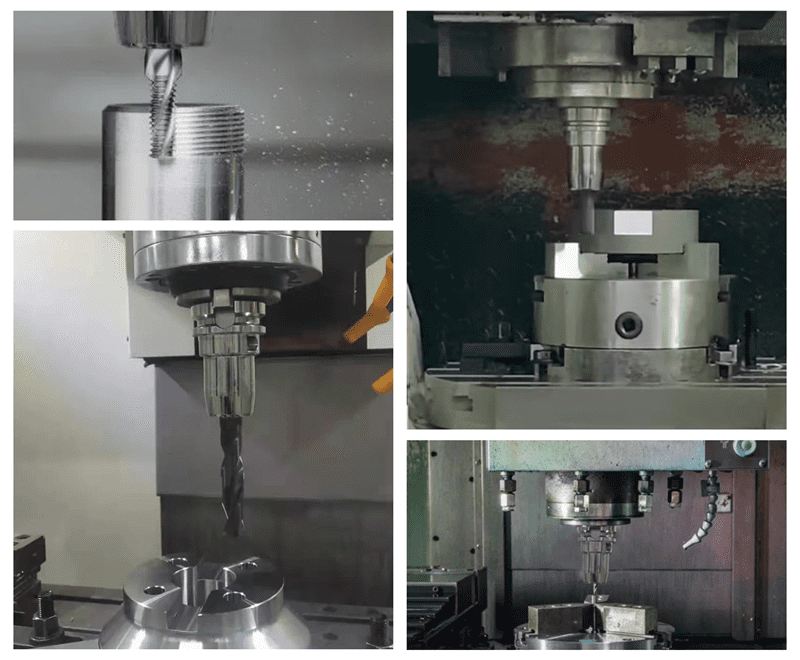

PSC tool holders are versatile and can be used in various machining operations, such as:

Turning Operations: External and internal turning, facing operations.

Milling Operations: Slot milling, face milling, contour milling.

Drilling Operations: High-precision drilling tasks.

Boring Operations: Precision boring for accurate results.

Multi-Tasking Machines: Combining turning and milling operations for enhanced efficiency.

Halnn offers a range of PSC tool holders designed to meet the highest standards of quality and performance. With unique features and innovations, Halnn's PSC tool holders provide unmatched rigidity, precision, and tool life. Case studies and success stories from satisfied customers highlight the exceptional performance of Halnn PSC tool holders in various applications.

Halnn PSC tool holders are manufactured using high-grade materials and advanced manufacturing techniques, ensuring top-notch quality and durability.

Halnn's innovative design and technological advancements provide unparalleled performance and reliability.

Halnn offers extensive support and services, including technical assistance, customization options, and prompt after-sales service.

By enhancing tool life and reducing downtime, Halnn PSC tool holders provide cost-effective machining solutions, delivering excellent value for investment.

Proper maintenance is crucial for ensuring the longevity and performance of PSC tool holders. Here are some tips for maintaining your PSC tool holders:

Regular Cleaning: Clean the tool holders regularly to prevent the buildup of debris and contaminants.

Proper Storage: Store the tool holders in a dry, clean environment to avoid corrosion and damage.

Timely Inspections: Conduct regular inspections to identify and address any signs of wear or damage.

Real-world feedback from satisfied Halnn customers underscores the performance and reliability of Halnn PSC tool holders. Success stories and performance highlights demonstrate how Halnn PSC tool holders have helped customers achieve superior machining results.

A PSC (Polygon Shank Coupling) tool holder is a tool holding system designed for high precision and stability in machining operations. It features a polygonal taper interface and flange contact, providing a strong, rigid connection between the tool and the machine.

PSC tool holders offer several benefits, including:

High rigidity and stability, reducing tool deflection and vibration.

Quick-change capability, minimizing downtime and increasing productivity.

Enhanced precision and accuracy in machining operations.

Improved tool life due to reduced wear and tear.

Versatility in various applications, including turning, milling, boring, and drilling.

The polygonal taper interface of the PSC tool holder provides exceptional rigidity and stability, which reduces tool deflection and vibration during machining. This results in superior surface finishes and enhanced machining accuracy.

Yes, PSC tool holders are versatile and can be used for various machining operations, including turning, milling, boring, and drilling. Halnn offers a comprehensive range of PSC tool holders suitable for different applications.

PSC tool holders are designed for rapid tool changes, significantly reducing downtime. The quick-change feature allows for seamless operation transitions without compromising precision, making it easier to switch tools quickly and efficiently.

Halnn offers a range of PSC tool holders, including:

PSC turning tool holders for high-precision turning operations.

PSC milling tool holders for various milling operations.

PSC boring tool holders for precision boring.

PSC drilling tool holders for high-precision drilling tasks.

The stability and precision offered by PSC tool holders minimize tool wear and tear, extending the tool life and reducing the frequency of replacements. This leads to cost savings and improved efficiency in machining operations.

Halnn PSC tool holders are manufactured using high-grade materials and advanced manufacturing techniques, ensuring top-notch quality and durability.

Yes, Halnn offers customization options for PSC tool holders to meet specific machining requirements. This ensures that the tool holders are tailored to provide optimal performance for various applications.

Proper maintenance is crucial for ensuring the longevity and performance of PSC tool holders. Regular cleaning, proper storage in a dry and clean environment, and timely inspections to identify wear or damage are recommended for maintaining PSC tool holders.

Halnn PSC tool holders stand out due to their superior quality, advanced design, and technological innovations. They offer exceptional rigidity, precision, and tool life, backed by comprehensive customer support and cost-effective machining solutions.

Halnn PSC tool holders can be purchased directly from Halnn's official website or through authorized distributors. For more information and to find a distributor near you, please visit the Halnn website or contact their sales team.

In the realm of machining, Halnn PSC tool holders represent the pinnacle of precision, efficiency, and reliability. Whether you are involved in high-precision turning, milling, drilling, or boring operations, Halnn’s PSC tool holders are designed to meet and exceed your expectations. Invest in Halnn PSC tool holders and experience a transformative improvement in your machining processes.

For more information about Halnn PSC tool holders and how they can benefit your operations, please visit our website or contact our sales team. Halnn is dedicated to providing cutting-edge solutions to meet your machining needs and drive your success.

Our website: https://www.halnncbn.com/

Mail address: halnntools@halnn-group.com

WhatsApp: +8615515925975

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone