In the world of gear manufacturing, precision and efficiency are paramount. One essential tool that stands out in this industry is the gear hob cutting tool. At Halnn, we are committed to providing top-tier gear hob cutting tools that meet the diverse needs of various industries, ensuring high-quality output and optimal performance.

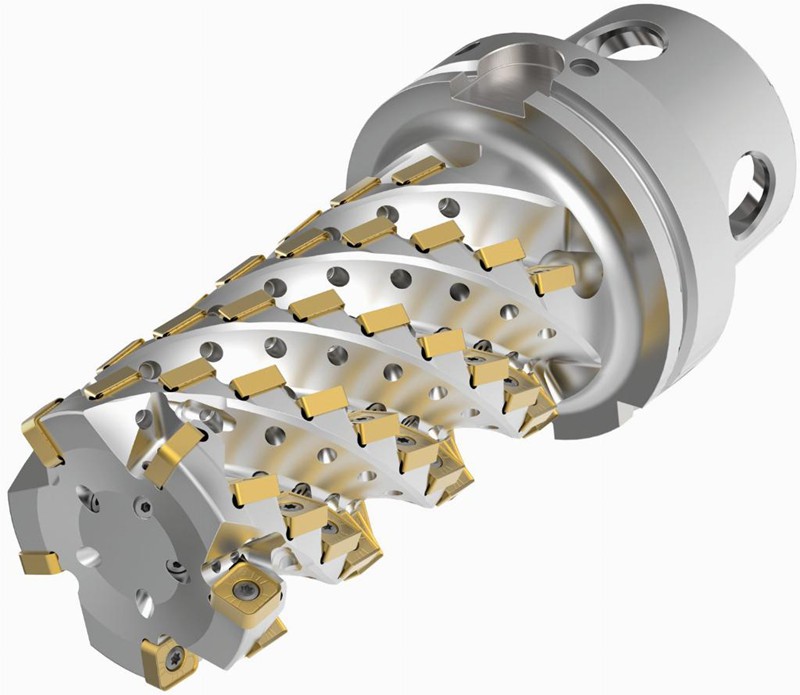

A gear hob cutting tool is a cylindrical tool used in the process of gear cutting, where it systematically removes material to shape the teeth of gears. This tool is integral to the hobbing process, a continuous cutting operation that produces precise and uniform gear teeth. Gear hob cutting tools come in various types, including solid hobs, indexable insert gear hobs, and hobs with indexable carbide inserts.

Gear hob cutting tools are indispensable in various industries due to their precision and efficiency. Key applications include:

Automotive Industry: Essential for manufacturing gears used in vehicle transmissions and drivetrains.

Heavy Machinery: Necessary for creating robust gears that can withstand heavy loads and harsh conditions.

Energy Sector: Critical for producing gears in wind turbines and other energy-generating machinery.

Choosing the right gear hob cutting tool can significantly enhance your manufacturing process. The key advantages include:

Precision and Accuracy: Ensures each gear tooth is cut to exact specifications.

Efficiency and Productivity: Reduces production time and increases throughput.

Cost-Effectiveness: Long-lasting tools reduce the need for frequent replacements.

Longevity and Durability: High-quality materials and coatings extend the tool's life.

At Halnn, we pride ourselves on offering a comprehensive range of gear hob cutting tools designed to meet the highest standards of quality and performance. Here’s what sets our tools apart:

Our gear hob cutting tools are crafted from high-quality carbide, providing superior durability and cutting efficiency. The addition of advanced coatings such as TiN, TiAlN, and others enhances the tool's performance by reducing wear and increasing heat resistance.

Halnn's gear hob cutting tools incorporate the latest technological advancements to ensure precise cutting and long tool life. Our indexable insert gear hobs and hobs with indexable carbide inserts are designed for easy maintenance and cost-effective operation, making them an excellent choice for modern manufacturing processes.

Our commitment to quality and innovation has helped numerous clients achieve their production goals. For instance, a leading automotive manufacturer significantly improved their gear production efficiency and precision using Halnn indexable insert gear hobs, resulting in reduced downtime and lower operational costs.

Selecting the appropriate gear hob cutting tool for your needs involves several considerations:

Material Compatibility: Ensure the tool material is suitable for the gear material being cut.

Application Requirements: Consider the specific requirements of your application, such as the gear size and precision needed.

Machine Compatibility: Verify that the tool is compatible with your gear cutting machinery.

Proper maintenance is crucial to extending the life of your gear hob cutting tools. Regular inspection and timely replacement of inserts can prevent wear and ensure consistent performance. Additionally, following best practices for tool storage and handling can further enhance durability.

A gear hob cutting tool is a cylindrical tool used in the gear manufacturing process. It systematically removes material to shape the teeth of gears, ensuring precision and uniformity in gear tooth profiles.

The main types of gear hob cutting tools include:

Solid Hobs: Made from high-speed steel or carbide, used for high-precision cutting.

Indexable Insert Gear Hobs: Feature replaceable inserts for cost-effective and easy maintenance.

Hobs with Indexable Carbide Inserts: Known for durability and high-speed cutting capabilities.

Gear hob cutting tools are typically made from high-speed steel (HSS) or carbide. These materials are chosen for their durability, cutting efficiency, and ability to withstand high temperatures.

Gear hob cutting tools are used in various industries, including:

Automotive: For manufacturing gears in transmissions and drivetrains.

Heavy Machinery: For creating robust gears that can endure heavy loads.

Energy: For gears used in wind turbines and other energy-generation machinery.

The key benefits of using gear hob cutting tools include:

Precision and Accuracy: Ensures exact specifications in gear teeth.

Efficiency and Productivity: Reduces production time and increases throughput.

Cost-Effectiveness: Durable tools lower the need for frequent replacements.

Longevity and Durability: Advanced materials and coatings extend tool life.

Indexable insert gear hobs have replaceable cutting inserts, making them cost-effective and easier to maintain. Solid hobs, on the other hand, are made from a single piece of material, usually high-speed steel or carbide, and are typically used for applications requiring high precision.

When selecting a gear hob cutting tool, consider the following factors:

Material Compatibility: The tool material should be suitable for the gear material being cut.

Application Requirements: Specific needs of your application, such as gear size and required precision.

Machine Compatibility: Ensure the tool fits your gear cutting machinery.

To extend the life of your gear hob cutting tool:

Regular Inspection: Check for signs of wear and tear regularly.

Timely Replacement of Inserts: Replace inserts before they become too worn.

Proper Storage and Handling: Store tools in a clean, dry environment and handle them with care.

Yes, gear hob cutting tools can be used for both rough and finish machining. However, the choice of tool and insert type, as well as machining parameters, will vary depending on the specific requirements of the roughing or finishing operation.

Halnn is dedicated to providing high-quality gear hob cutting tools designed to meet the highest standards of precision and performance. Our tools are crafted from advanced materials, incorporate the latest technologies, and are tailored to meet the diverse needs of various industries. We offer a range of products, including solid hobs, indexable insert gear hobs, and hobs with indexable carbide inserts, ensuring we have the right solution for your gear manufacturing needs.

In conclusion, gear hob cutting tools are vital for achieving precision and efficiency in gear manufacturing. Halnn is dedicated to providing high-quality gear hob cutting tools that cater to the needs of various industries, ensuring superior performance and cost-effectiveness. Whether you need solid hobs, indexable insert gear hobs, or hobs with indexable carbide inserts, Halnn has the expertise and innovation to meet your requirements. Contact us today to learn more about our products and how we can help optimize your gear manufacturing.

Our website: https://www.halnncbn.com/

Mail address: halnntools@halnn-group.com

WhatsApp: +8615515925975

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone