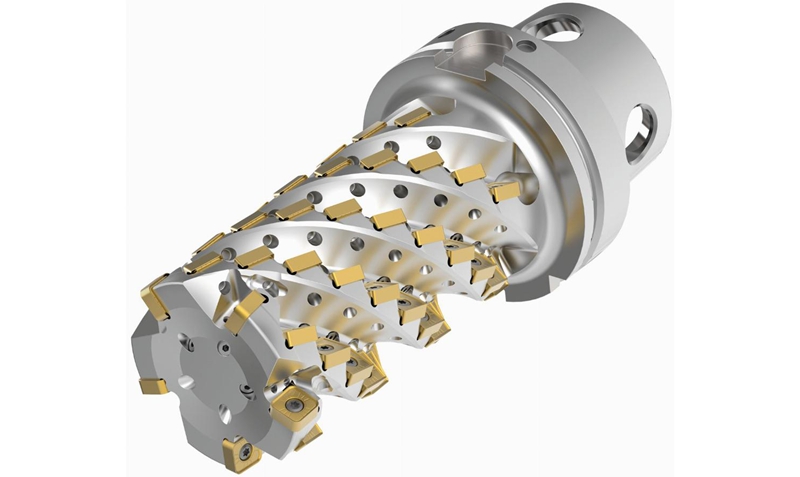

In the intricate world of gear manufacturing, precision and efficiency are paramount. Gear milling cutter inserts play a crucial role in achieving these goals. As an industry leader, Halnn offers a comprehensive range of high-quality gear milling cutter inserts designed to meet the diverse needs of manufacturers. This article explores the gear milling cutter inserts, their applications, and the advantages they bring to the gear production process.

A gear milling cutter insert is a replaceable cutting tool used in gear manufacturing to cut the precise shapes of gears. These inserts are essential for achieving the high levels of precision required in gear production. Unlike traditional gear cutting tools, which need frequent sharpening, gear milling cutter inserts can be easily replaced, ensuring consistent performance and reducing downtime.

Gear milling cutter inserts ensure high precision and accuracy, essential for producing gears that meet stringent quality standards.

These inserts are cost-efficient as they can be replaced individually, reducing the need for frequent sharpening and tool replacements.

Gear milling cutter inserts are versatile and can be used for various gear types and sizes, making them an excellent choice for manufacturers with diverse needs.

Replacing gear milling cutter inserts is straightforward, minimizing downtime and ensuring continuous production.

Gear milling cutter inserts are used across various industries, including automotive and heavy machinery. Their precision and efficiency make them ideal for producing high-quality gears essential for these sectors.

In the automotive industry, gear milling cutter inserts are used to produce gears for transmissions, differentials, and other critical components.

Heavy machinery manufacturers use these inserts to produce durable and reliable gears capable of withstanding harsh operating conditions.

Choosing the right gear milling cutter insert involves considering factors such as material, coating, and the specific application. It is essential to select an insert that offers the best balance of performance and cost-efficiency for the intended use.

Ensure the insert material matches the material being cut.

Use the appropriate coating for the application.

Follow manufacturer recommendations for speed and feed rates.

Using the wrong insert material for the application.

Ignoring recommended speed and feed rates.

Failing to replace worn inserts promptly.

Halnn offers a wide range of gear milling cutter inserts designed to meet the diverse needs of gear manufacturers. Our products are known for their precision, durability, and cost-efficiency. Whether you need carbide, CBN, or PCD inserts, Halnn has the right solution for you.

High precision and accuracy

Long lifespan and durability

Cost-effective solutions

Versatile applications

To maximize the lifespan of your gear milling cutter inserts, follow these maintenance and replacement tips:

Regularly inspect inserts for wear and damage.

Replace worn inserts promptly to maintain cutting performance.

Store inserts properly to prevent damage.

Gear milling cutter inserts are essential tools in the gear manufacturing process, offering precision, cost-efficiency, and versatility. Halnn range of high-quality inserts provides manufacturers with reliable solutions for producing high-quality gears. Contact Halnn today to learn more about our products and how they can benefit your operations.

A gear milling cutter insert is a replaceable cutting tool used in gear manufacturing to precisely shape gears. These inserts provide high precision and efficiency, making them essential for achieving consistent quality in gear production.

Gear milling cutter inserts are typically made from materials like carbide. Each material offers unique benefits in terms of hardness, wear resistance, and suitability for different types of gear materials.

Precision and Accuracy: Gear milling cutter inserts ensure high levels of precision and accuracy, which are critical for producing high-quality gears.

Cost-Efficiency: These inserts can be easily replaced, reducing the need for frequent sharpening and lowering overall production costs.

Versatility: They can be used for various gear types and sizes, making them adaptable to different manufacturing needs.

Ease of Replacement: The simple replacement process minimizes downtime and ensures continuous production.

Selecting the right insert involves considering factors such as:

The material of the gear being cut.

The desired coating on the insert for enhanced performance.

The specific requirements of your gear production process, such as speed, feed rates, and precision levels.

Gear milling cutter inserts are widely used in various industries, including:

Automotive: For manufacturing gears in transmissions, differentials, and other critical components.

Heavy Machinery: For creating durable and reliable gears capable of withstanding harsh operating conditions.

Match the insert material to the gear material being cut.

Use the appropriate coating for the application.

Follow the manufacturer’s recommendations for speed and feed rates.

Regularly inspect and replace worn inserts to maintain cutting performance.

Using the wrong insert material for the application.

Ignoring recommended speed and feed rates.

Failing to replace worn inserts promptly, leading to poor cutting performance and potential damage to the gear.

By offering high precision and reducing the need for frequent tool sharpening, gear milling cutter inserts lower overall production costs. Their ease of replacement also minimizes downtime, further contributing to cost savings.

Halnn provides a wide range of high-quality gear milling cutter inserts designed for precision, durability, and cost-efficiency. Our products cater to various gear manufacturing needs, ensuring reliable performance and superior results.

For more information about Halnn gear milling cutter inserts, or to request a quote, please visit our website or contact our sales team. Let Halnn help you achieve the precision and efficiency your gear manufacturing process demands.

Our website: https://www.halnncbn.com/

Mail address: halnntools@halnn-group.com

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone